The Cold Standing Seam Making Machine Revolutionizing Metal Roofing

In recent years, the construction and roofing industries have witnessed a significant evolution in technology, particularly when it comes to the tools that professionals use. Among these innovations, the cold standing seam making machine has emerged as a groundbreaking piece of equipment in the realm of metal roofing. This specialized machine is designed to produce standing seam roofing panels efficiently and with precision, elevating the quality and durability of roofing systems.

Understanding Cold Standing Seam Roofing

Cold standing seam roofing is a type of metal roofing that involves vertical seams that are raised above the flat surface of the panels. The seams are mechanically locked and do not require any welding or heat, which is particularly advantageous in various construction scenarios. Cold standing seam roofs are highly regarded for their strength, leak resistance, and aesthetic appeal. They are often made from materials like aluminum, steel, and copper, providing a versatile option for both residential and commercial applications.

The Role of the Cold Standing Seam Making Machine

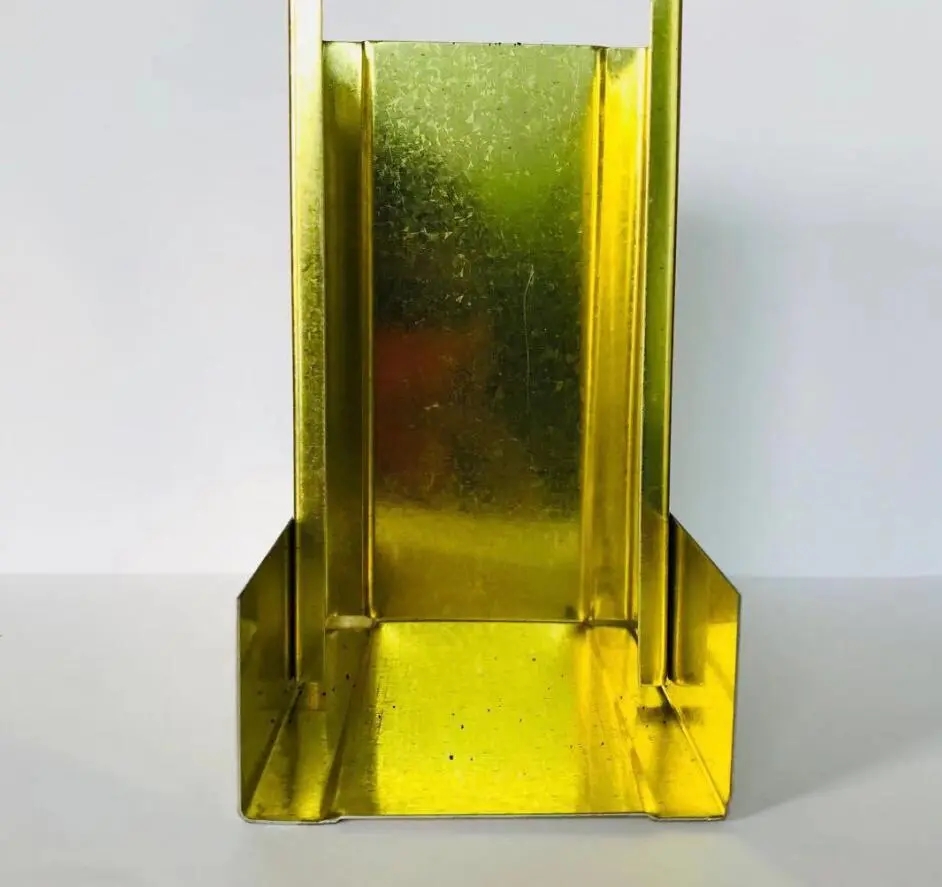

The cold standing seam making machine is crucial in the manufacturing process of these roofing panels. This machine operates by taking flat metal sheets and shaping them into standing seam profiles that can be seamlessly installed on rooftops. The benefits of using this machine are numerous

1. Precision Engineering The machine ensures that each seam is formed accurately, which is essential for effective installation and long-lasting performance. Accurate seams help prevent leaks, enhancing the roof's ability to withstand various weather conditions.

2. Efficiency Traditional methods of seam making can be time-consuming and labor-intensive. The cold standing seam making machine automates this process, significantly increasing production speed while reducing labor costs. This efficiency allows contractors to complete projects in a timely manner, meeting tight deadlines without compromising quality.

3. Versatility Cold standing seam making machines can be adjusted to create different widths and profiles of seams, facilitating customization for specific projects. This adaptability not only allows for unique architectural designs but also accommodates the varying preferences of clients.

4. Quality Control With advanced technology incorporated into these machines, manufacturers can maintain high standards of quality. The machines are often equipped with sensors and monitoring systems that detect any discrepancies in the manufacturing process, ensuring that only the best products reach the market.

5. Reduced Waste The precise cutting and shaping capabilities of these machines result in minimal waste during production. This not only reduces costs but also aligns with environmentally friendly practices by promoting the efficient use of materials.

Conclusion

As the construction industry continues to adapt to modern demands, the cold standing seam making machine stands out as a vital tool that enhances both productivity and quality in metal roofing. Its capacity to produce durable, aesthetically pleasing roofing solutions quickly and efficiently speaks to the needs of today’s builders and homeowners alike. With an increasing focus on sustainability and efficiency, the adoption of such innovative machinery is likely to increase, further transforming the landscape of roofing technology. The cold standing seam making machine is not just a piece of equipment; it is a significant leap toward a more efficient and reliable construction future.