The Benefits of Using IBR Roof Sheet Making Machines

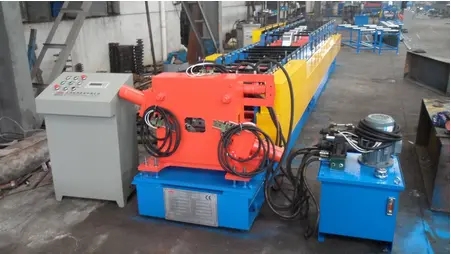

In the construction and building industry, the quality and durability of roofing materials play a crucial role in ensuring the longevity and safety of structures. One innovative solution that has gained significant traction in recent years is the IBR (Inverted Box Rib) roof sheet making machine. This advanced machinery is designed for producing high-quality IBR roof sheets, which are widely used in commercial and residential roofing projects. In this article, we explore the benefits of using IBR roof sheet making machines and their impact on the construction sector.

High Efficiency and Automation

IBR roof sheet making machines are engineered for high efficiency and automation, significantly reducing the time and labor required for production. With automated controls and precise engineering, these machines can convert raw materials, typically galvanized steel or aluminum coils, into uniform, ready-to-install roof sheets quickly. This efficiency is especially vital for large-scale construction projects where time is often of the essence.

Cost-Effective Production

The Benefits of Using IBR Roof Sheet Making Machines

Durability and Strength

IBR roof sheets are known for their strength and durability. The design of the IBR profile provides superior structural integrity compared to traditional flat sheets. This design enables the roof to withstand various weather conditions, including heavy rain, strong winds, and even hail. When produced using high-quality materials and machinery, IBR roof sheets can offer long-lasting performance, making them a reliable choice for both builders and owners.

Versatility in Application

Another significant advantage of IBR roof sheet making machines is their versatility. IBR roof sheets are suitable for a wide range of applications, from industrial warehouses and commercial buildings to residential homes and agricultural structures. The ability to customize sheet lengths, colors, and coatings according to specific project requirements means that builders can cater to diverse architectural styles and functional needs.

Eco-Friendly Option

In today’s environmentally-conscious market, sustainability is a key consideration for many construction projects. IBR roof sheets, particularly when made from recycled materials, can be a more eco-friendly roofing option. Moreover, their longevity and durability reduce the need for frequent replacements, contributing to less waste over time. Investing in energy-efficient machinery also means that manufacturers can lessen their carbon footprint during the production process.

Conclusion

In summary, IBR roof sheet making machines are revolutionizing the roofing industry by providing efficient, cost-effective, and durable roofing solutions. Their ability to automate production and customize outputs caters to the various needs of the construction market, making them an invaluable asset for businesses looking to elevate their offerings. As the demand for high-quality roofing materials continues to grow, the use of IBR roof sheet making machines is likely to expand, solidifying their place as a cornerstone of modern construction practices. By embracing this technology, builders can not only enhance their efficiency but also contribute to sustainable development in the construction industry.