Enhancing Roofing Solutions The IBR Roofing Sheet Making Machine

In the realm of construction and architecture, roofing plays a critical role in ensuring the durability and aesthetic appeal of buildings. Among various roofing options available, IBR (Industrial and Building Roofing) sheets have gained significant popularity due to their unique blend of strength, versatility, and cost-effectiveness. At the heart of manufacturing these durable roofing solutions lies the innovative IBR roofing sheet making machine, which streamlines production and enhances the quality of roofing materials.

Understanding IBR Roofing Sheets

IBR roofing sheets are characterized by their distinctive profile, featuring a series of trapezoidal or curved designs that provide not only aesthetic appeal but also superior structural integrity. These sheets are widely used in both residential and industrial applications, owing to their ability to withstand harsh weather conditions while being lightweight and easy to install.

The IBR sheets can be made from various materials, including galvanized steel, aluminum, and even plastic composites, catering to a wide range of preferences and requirements. Their resistance to rust and corrosion significantly extends their lifespan, making them a favored choice for architects and builders alike.

The Role of IBR Roofing Sheet Making Machines

The transition from raw materials to finished products is crucial in the manufacturing process of IBR roofing sheets. This is where the IBR roofing sheet making machine comes into play. These machines are designed to produce roofing sheets efficiently while maintaining high-quality standards.

1. Automated Production Modern IBR roofing sheet making machines are equipped with advanced automation technology. This ensures that the production process is streamlined, minimizing human error and maximizing output. The automation also allows for continuous production, which is essential in meeting large-scale construction demands.

2. Customizable Specifications One of the standout features of these machines is their ability to produce sheets of various thicknesses, lengths, and profiles. This level of customization ensures that builders and architects can obtain specific products tailored to their project needs, enhancing the application and aesthetic of the roofs being constructed.

3. Energy Efficiency With global attention increasingly shifting towards sustainability, energy-efficient machinery has become a priority in the manufacturing sector. IBR roofing sheet making machines are designed to consume less energy while delivering optimal performance. This not only reduces operational costs but also aligns with environmentally friendly practices.

4. Robust Construction and Longevity The machines are built to handle tough operational demands, producing durable IBR sheets consistently. High-quality components, such as steel frames and advanced gear systems, contribute to the longevity of the machinery, making it a worthwhile investment for manufacturers.

The Manufacturing Process

The manufacturing process of IBR roofing sheets involves several key steps, all facilitated by the IBR roofing sheet making machine

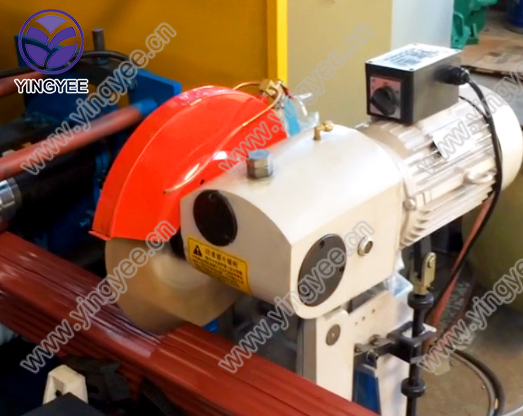

1. Coil Preparation Raw material coils, usually galvanized steel, are made ready for processing. These coils are unwound and fed into the machine. 2. Forming The machine then passes the unwound coils through a series of rollers that progressively form the IBR profile. This shaping process is critical as it determines the strength and integrity of the final product. 3. Cutting Once the desired length is achieved, the continuous sheet is cut to size. The cutting mechanism on the machine ensures precise dimensions, which is vital for construction application.

4. Quality Inspection After forming and cutting, the sheets undergo a quality inspection process to ensure they meet industry standards. This step is crucial in maintaining the reputation of manufacturers and the safety of end-users.

Conclusion

As the demand for durable and efficient roofing solutions continues to rise, the role of the IBR roofing sheet making machine becomes increasingly significant. By combining advanced technology, customization options, and energy efficiency, these machines play a crucial role in revolutionizing the roofing industry. For manufacturers and builders, investing in an IBR roofing sheet making machine not only enhances their production capabilities but also positions them competitively in a rapidly evolving market. The future of roofing solutions looks bright, with IBR sheets leading the way in innovation and sustainability.