The Significance of IBR Roofing Sheet Making Machines in Modern Construction

In the ever-evolving landscape of construction, efficiency and durability are paramount. One key innovation that has gained prominence in the building materials sector is the IBR roofing sheet making machine. IBR, which stands for Inverted Box Rib, refers to a specific profile of metal roofing sheets that are renowned for their strength, aesthetic appeal, and ease of installation. This article explores the significance of IBR roofing sheet making machines, their operational advantages, and their role in modern construction practices.

Understanding IBR Roofing Sheets

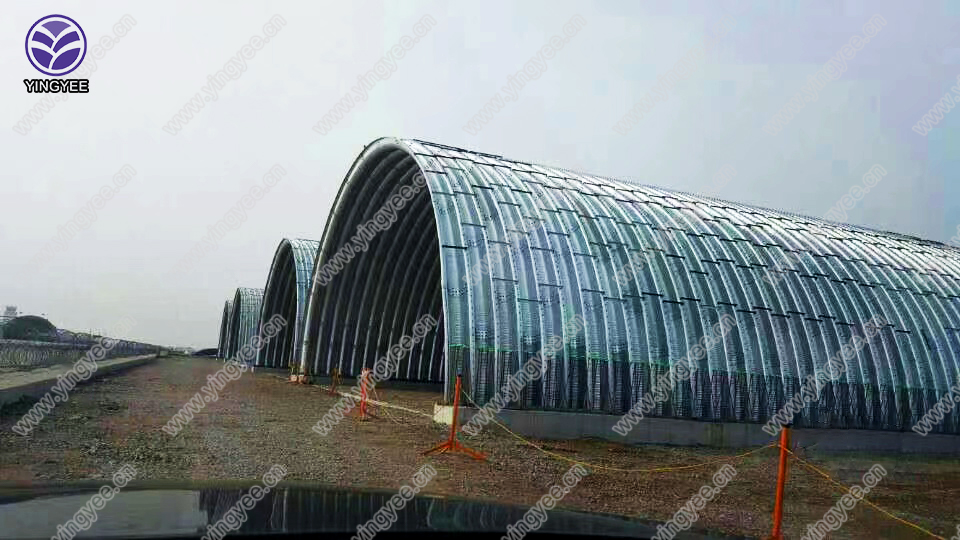

IBR roofing sheets are designed with a unique ribbed profile that enhances their structural integrity. This design allows these sheets to bear heavy loads while providing excellent resistance against harsh weather conditions, such as heavy rain, hail, and strong winds. Additionally, IBR sheets are lightweight, making them easier to handle and install compared to traditional roofing materials. Their modern aesthetic appeal has made them a popular choice for residential, commercial, and industrial buildings.

The Role of IBR Roofing Sheet Making Machines

IBR roofing sheet making machines are specialized equipment designed to manufacture these robust roofing sheets efficiently. The production process usually involves feeding metal coils into the machine, where they undergo several steps, including shearing, rolling, and cutting. The technology incorporated in these machines allows for precision engineering, ensuring that each sheet produced meets stringent quality standards.

One of the significant advantages of using IBR roofing sheet making machines is their capacity to produce sheets at a rapid pace. This rapid production is crucial in meeting the growing demands of the construction industry. In addition to high output, these machines also offer customization options. Manufacturers can adjust the thickness, length, and color of the sheets, catering to specific customer requirements and preferences.

Energy Efficiency and Cost-effectiveness

Modern IBR roofing sheet making machines are designed with energy efficiency in mind. They typically consume less power than older models, reducing operational costs for manufacturers. Furthermore, the machines are built for longevity with minimal maintenance needs, ensuring that investment costs are kept low in the long run. This reduction in operational costs allows manufacturers to offer competitive pricing to customers, making IBR sheets more accessible within the market.

Eco-friendliness and Sustainability

In today's environmentally conscious world, utilizing eco-friendly materials and processes is more critical than ever. IBR roofing sheets are often made from recyclable materials, contributing to sustainability in construction. Furthermore, the energy-efficient production methods employed by modern IBR sheet making machines minimize waste and reduce the carbon footprint associated with manufacturing.

Conclusion

The advent of IBR roofing sheet making machines has significantly transformed the construction materials landscape, offering a perfect blend of durability, aesthetics, and efficiency. As the demand for high-quality roofing solutions continues to rise, these machines will play a crucial role in meeting industry needs. Their ability to produce customizable, energy-efficient, and eco-friendly roofing sheets positions them as an essential asset for manufacturers in the construction sector. As technology advances, we can expect further enhancements in these machines, leading to even greater innovations in building materials. In conclusion, investing in IBR roofing sheet making machines is not just a production choice; it is a commitment to quality, efficiency, and sustainability in the modern construction industry.