The Innovations in IBR Roofing Sheet Making Machines

In the realm of construction and building materials, the importance of roofing systems cannot be overstated. Among the different types of roofing sheets available in the market, IBR (Inverted Box Profile) roofing sheets have gained popularity due to their distinct advantages. To cater to the rising demand for IBR roofing sheets, manufacturers have developed specialized machines known as IBR roofing sheet making machines. These machines play a vital role in producing high-quality roofing sheets efficiently and effectively.

Understanding IBR Roofing Sheets

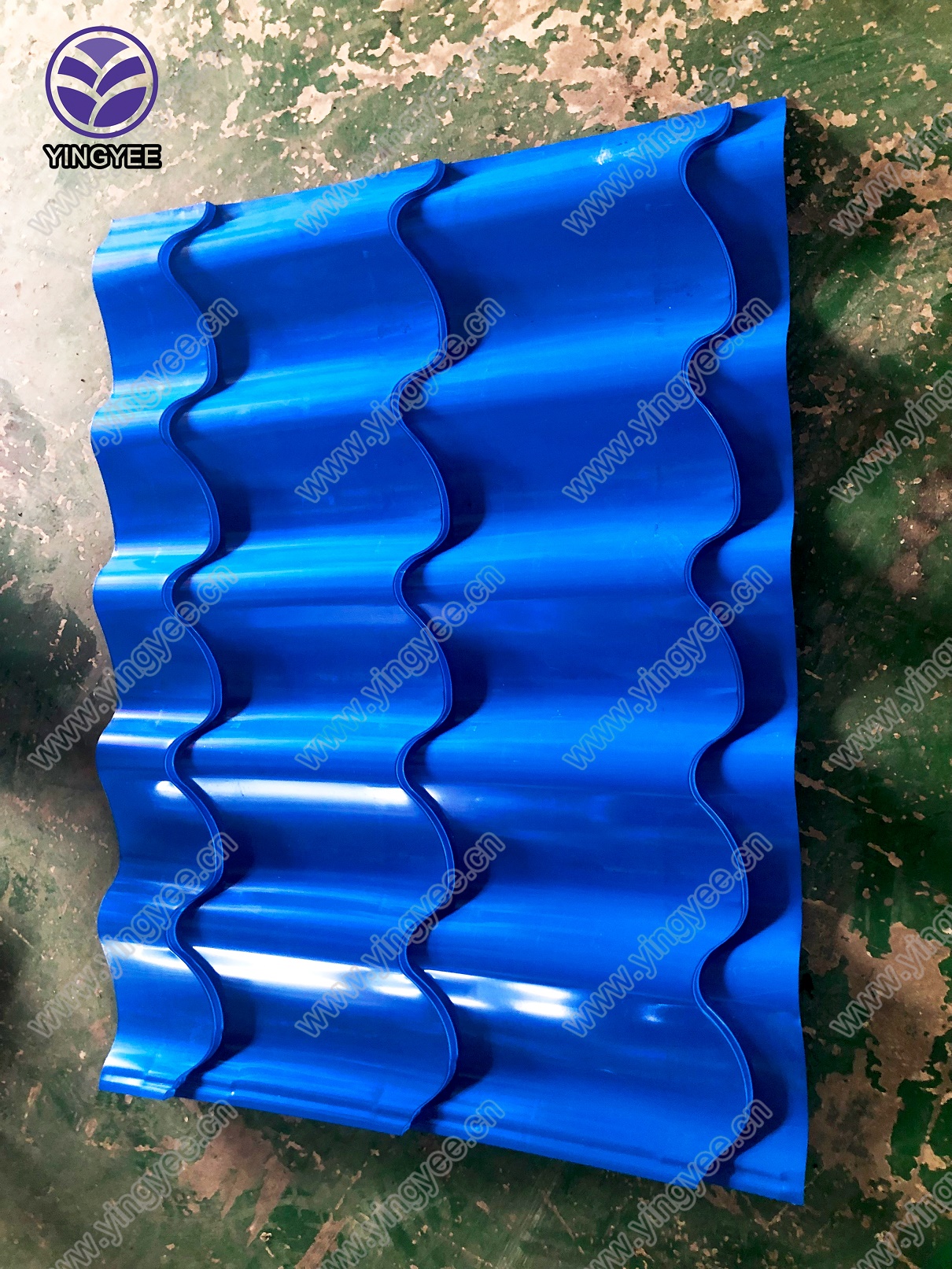

IBR roofing sheets are characterized by their unique inverted box shape, which provides enhanced strength and durability. The design allows for better load distribution and improves water run-off, making these sheets ideal for regions prone to heavy rainfall. IBR sheets come in varying thicknesses and lengths, suitable for various applications, including industrial buildings, warehouses, and residential homes.

The Role of IBR Roofing Sheet Making Machines

The IBR roofing sheet making machine is a state-of-the-art equipment that automates the production process of these roofing sheets

. The machine can efficiently convert raw materials, typically galvanized steel or aluminum, into precisely shaped and cut roofing sheets, optimizing both time and labor resources.Key features of these machines typically include

1. High Production Capacity Modern IBR roofing sheet making machines are designed for high output without compromising quality. They can produce extensive lengths of sheets in a short period, making them perfect for large-scale projects.

2. Customization Options Many machines are equipped with adjustable parameters, allowing manufacturers to customize sheet dimensions and thicknesses. This versatility is crucial for meeting various customer requirements.

3. Durability and Reliability These machines are built to withstand rigorous working conditions. Their robust construction ensures longevity and reliability, essential for any manufacturing setup.

4. User-Friendly Operation Contemporary IBR roofing sheet making machines often feature advanced control systems, enabling operators to manage the process with minimal training. This increases productivity and ensures quality control.

5. Cost Efficiency The automation of the production process reduces labor costs and minimizes human error. Additionally, modern machines utilize materials efficiently, reducing wastage and thereby lowering production costs.

Technological Advancements

The advent of technology has further enhanced the capabilities of IBR roofing sheet making machines. Incorporating computer numerical control (CNC) technology and advanced software, operators can achieve precise measurements and uniformity in production. Additionally, features like remote monitoring and maintenance alerts ensure that machines operate at optimal efficiency.

Moreover, with the growing focus on sustainability, manufacturers are now producing machines that require less energy and generate minimal waste during production. These eco-friendly innovations resonate with current industry trends prioritizing environmental responsibility.

Conclusion

The IBR roofing sheet making machine is an indispensable tool in the production of high-quality roofing materials. Its ability to create durable, efficient, and cost-effective roofing solutions has made it a standard in the construction industry. As technology continues to evolve, we can expect further enhancements that will improve efficiency and sustainability in production processes.

With the increasing demand for robust roofing solutions across various sectors, investing in advanced IBR roofing sheet making machines is not just a necessity but a strategic move for manufacturers looking to stay competitive in the market. Ultimately, these machines are not just about producing roofing sheets; they symbolize progress and innovation within the construction industry, paving the way for safer and more durable building structures around the world.