Understanding IBR Roll Forming Machines A Comprehensive Overview

Roll forming technology has revolutionized the manufacturing industry by providing a highly efficient method for producing metal profiles with uniformity and precision. Among the various applications of roll forming, the IBR (Inverted Box Rib) profile is particularly noteworthy due to its robustness and versatility in construction applications. This article delves into the intricacies of IBR roll forming machines, highlighting their design, operation, and benefits.

What is IBR Roll Forming?

IBR profiles are specifically designed metal sheets characterized by their inverted box ribs. These profiles are commonly used in roofing and wall cladding applications due to their structural integrity and aesthetic appeal. The IBR design enhances the strength of the sheets while allowing for quick drainage of water, thereby preventing potential water pooling and damage. The unique rib pattern also contributes to the overall rigidity of the material, making it an ideal choice for various building structures.

The Mechanism Behind IBR Roll Forming Machines

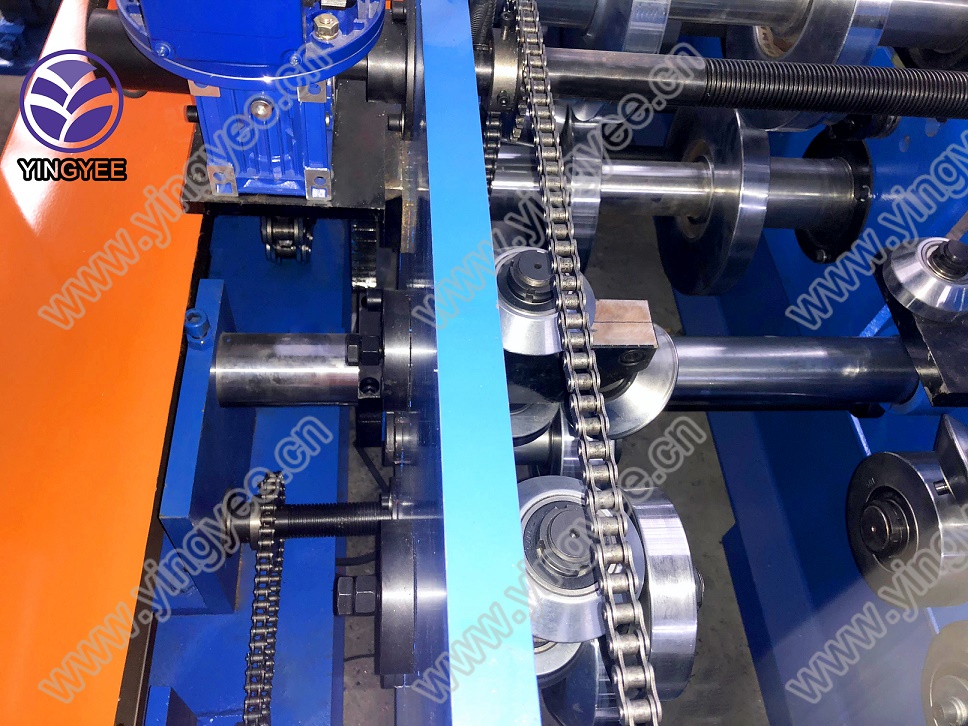

IBR roll forming machines are specialized equipment that convert flat metal sheets into the desired IBR profile through a continuous bending process

. The core components of these machines include1. Feeding System This component guides the flat metal sheet into the rollers. The machine can handle different widths and thicknesses of metal sheets, accommodating various production needs.

2. Rollers The heart of the roll forming machine consists of multiple sets of rollers that progressively shape the metal. Each roller station is designed to impart a specific bend or contour. The precision of these rollers is crucial for achieving consistent profiles.

3. Cutting Mechanism After the metal has been shaped into the IBR profile, the machine requires a cutting mechanism to produce sheets of specific lengths. This can be done using either a mechanical or hydraulic cutter, depending on the machine’s design.

4. Control System Modern IBR roll forming machines are equipped with advanced control systems, often featuring PLC (Programmable Logic Controller) technology. This allows for precise adjustments of speed, temperature, and cutting length, ensuring optimal performance and product quality.

Benefits of Using IBR Roll Forming Machines

1. Efficiency IBR roll forming machines are designed for high production rates. The automated nature of the process reduces labor costs and minimizes human error, making it an efficient manufacturing solution.

2. Consistency and Precision One of the most notable advantages of roll forming is its ability to produce uniform profiles. The continuous process ensures that every sheet maintains the same dimensions and quality, which is essential in construction applications.

3. Material Utilization Roll forming produces minimal waste since the metal is shaped rather than cut away. This is particularly advantageous in large-scale production runs, where material costs can significantly impact profitability.

4. Versatility IBR roll forming machines can be customized to produce various profiles beyond the traditional IBR shape. This flexibility allows manufacturers to adapt to changing market demands and offer diverse product lines.

5. Strength The IBR profile is known for its enhanced structural strength, making it suitable for roofing systems that must withstand heavy loads, such as snow or potential impact forces.

Conclusion

In conclusion, IBR roll forming machines are a vital tool in the modern manufacturing landscape, offering efficiency, precision, and versatility for producing metal profiles. The IBR profile itself is a testament to the advancements in roll forming technology, providing a solution that meets the demands of the construction industry. As demand for durable and efficient building materials continues to rise, the importance of IBR roll forming machines in manufacturing processes will only increase, shaping the future of construction materials with their innovative designs and robust performance. Investing in such machines not only enhances production capabilities but also ensures that manufacturers remain competitive in a rapidly evolving market.