Understanding IBR Profiles and Double Layer Roofing Forming Machines

In the realm of construction and roofing, IBR (Inverted Box Rib) profiles have gained prominence due to their strong structural integrity and aesthetic appeal. Commonly used in industrial, commercial, and residential buildings, these profiles offer excellent durability, making them ideal for various roofing solutions. Their unique ribs not only contribute to strength but also facilitate efficient water runoff, ultimately extending the lifespan of roofing systems.

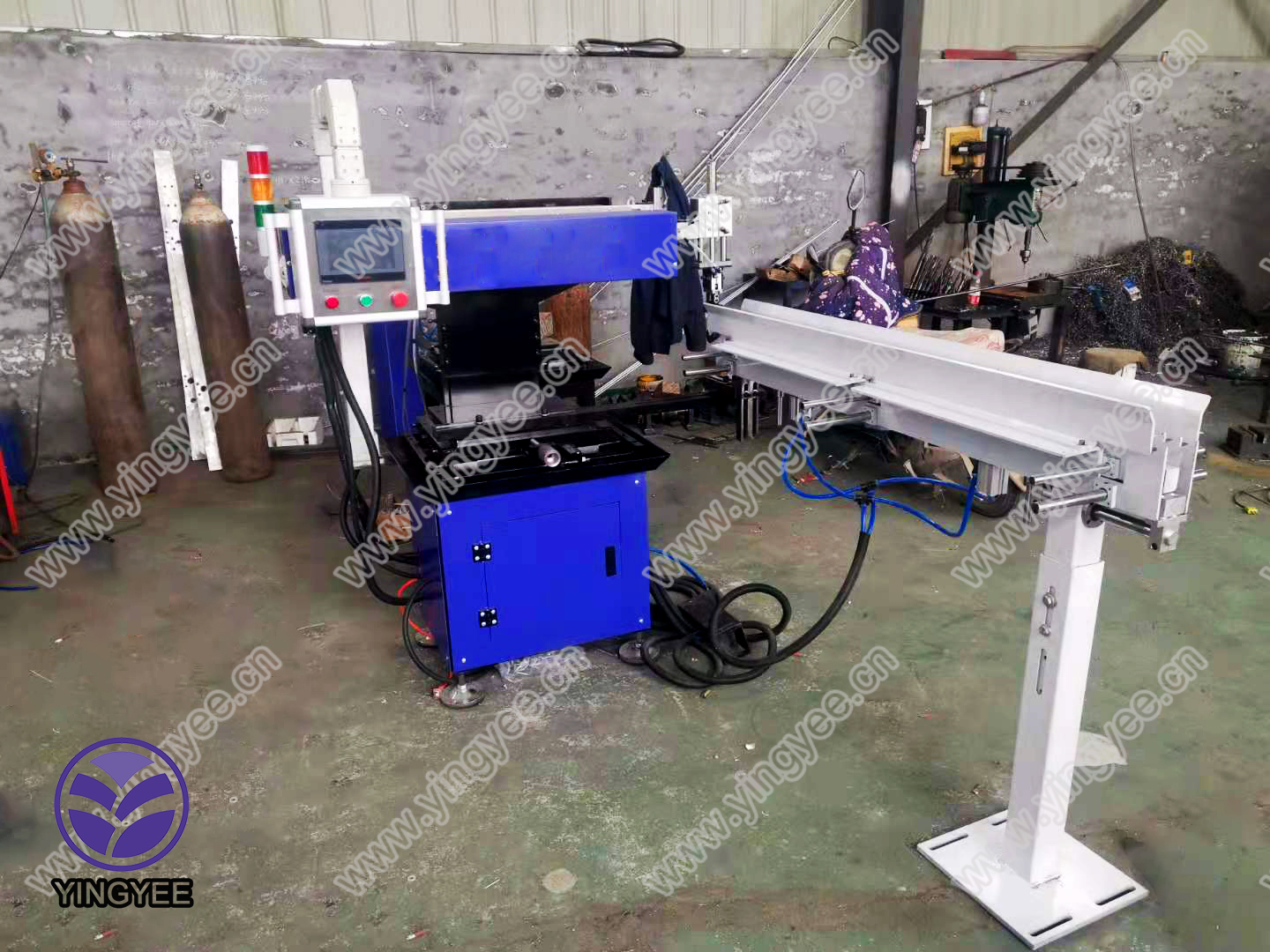

To efficiently produce IBR profiles, manufacturers often rely on advanced machinery, specifically double layer roofing forming machines. These machines are designed to create different profiles simultaneously, thereby increasing production efficiency and reducing the need for multiple equipment types. The dual-layer capability of these machines allows for the creation of two different profile types in one continuous process, thereby saving on production costs and time.

How Double Layer Roofing Forming Machines Work

The operation of a double layer roofing forming machine involves several steps. Initially, coils of metal are fed into the machine. The machine employs a series of rollers that shape the metal sheets into the desired profiles. Because it can produce two layers or types of profiles—such as IBR and trapezoidal profiles—it provides significant versatility for manufacturers. This versatility is invaluable in meeting varying customer demands without necessitating extensive changes in equipment or processes.

Moreover, these machines are equipped with computerized control systems that enhance precision and quality. The automated nature of the machines means that each profile can be manufactured to exact specifications, ensuring consistency across production runs. This is particularly important for construction projects where uniformity and reliability are critical.

Benefits of Using Double Layer Roofing Forming Machines

Investing in a double layer roofing forming machine offers numerous advantages. Firstly, it enhances productivity by allowing manufacturers to produce multiple profiles in a single pass, significantly reducing downtime. Secondly, the machine's ability to handle varying profiles without the need for extensive reconfiguration leads to lower operational costs and increased efficiency.

Additionally, the quality of the finished products is superior, thanks to the precision engineering involved in the forming process. This results in reduced waste materials and increased profitability for manufacturers.

In conclusion, IBR profiles are a key component in modern roofing solutions, and double layer roofing forming machines play a crucial role in their production. With their ability to produce multiple profiles efficiently and with high quality, these machines offer significant benefits to manufacturers, ensuring they meet the demands of a competitive market while maintaining cost-effectiveness.