Understanding IBR Profiles for Double Layer Roofing Forming Machines

In the construction and building industry, the importance of durable and efficient roofing solutions cannot be overstated. One of the most innovative methods to achieve this is through the use of IBR (Inverted Box Rib) profiles, particularly with double layer roofing forming machines. This advanced technology enhances the design, robustness, and installation efficiency of roofing materials.

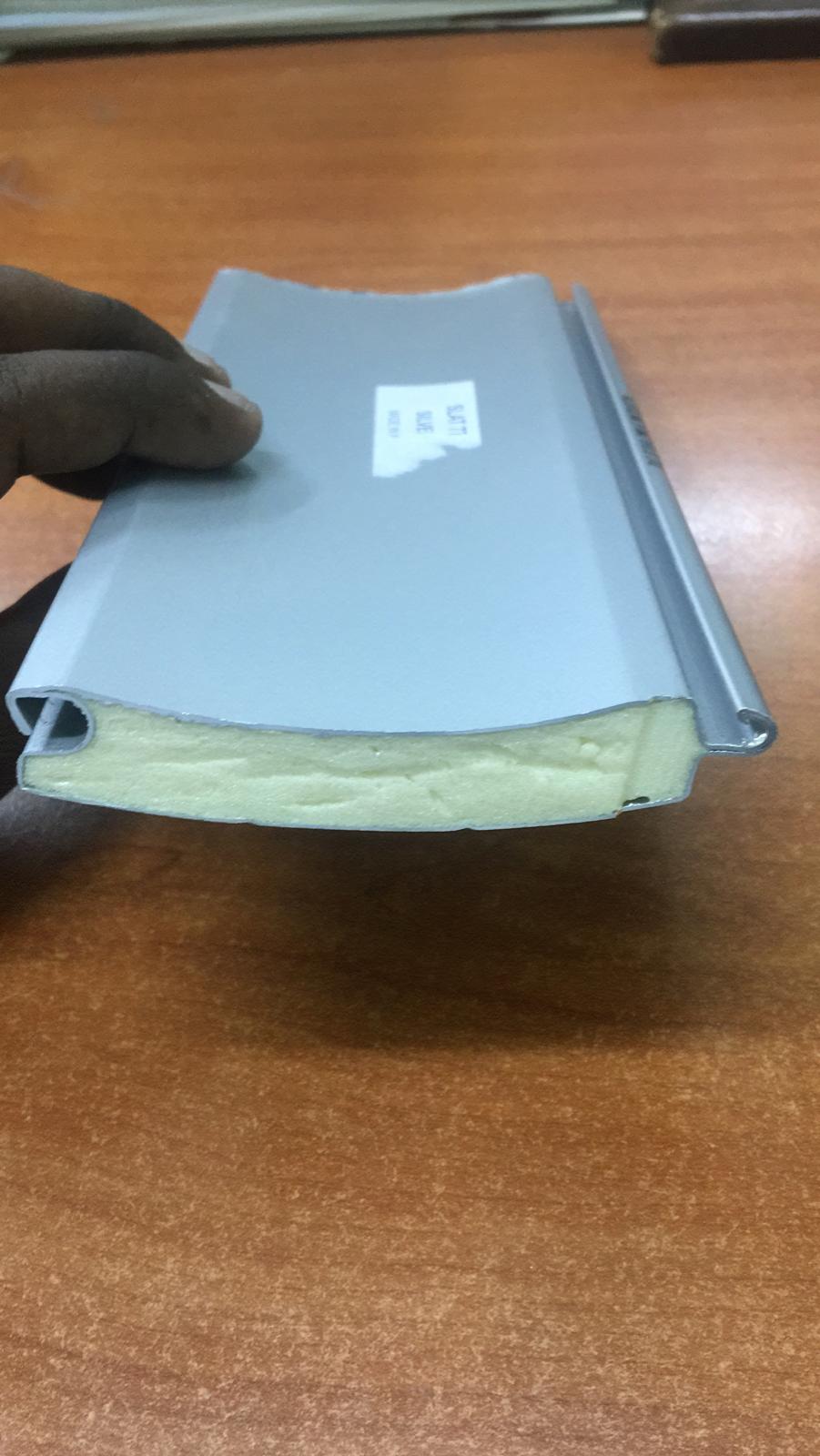

IBR panels are characterized by their unique ribbed design, which not only adds aesthetic value but also provides superior strength and rigidity. When utilized in double layer roofing systems, these profiles create an effective barrier against environmental elements while also allowing for enhanced insulation properties. The double layer architecture typically involves one layer of IBR roofing acting as the outer shell, while the second layer functions as insulation, ensuring that buildings remain well-ventilated and energy-efficient.

Double layer roofing forming machines are specially designed to create these complex profiles with high precision. The machines combine advanced technology with robust engineering to produce consistent and high-quality roofing sheets. An IBR profile machine generally includes various components such as a decoiler, roll forming system, cutting mechanism, and a control panel, making it easier for manufacturers to produce panels of different lengths and thicknesses based on their specific needs.

Additionally, the versatility of IBR profiles makes them suitable for a wide range of applications, from residential homes to large industrial facilities. By utilizing double layer IBR roofing, builders can achieve a greater level of customization in their designs, as these panels can be manufactured in varying colors and finishes. This not only boosts the aesthetic appeal but also allows for better integration with the overall architectural design of a structure.

Moreover, the installation of IBR roofing systems is relatively straightforward due to their lightweight nature. This ease of handling reduces labor costs and installation time, contributing to more efficient project timelines. As sustainability becomes increasingly crucial in construction, the durability and energy efficiency of IBR double layer roofing systems position them as a valuable choice for modern building needs.

In conclusion, IBR profiles utilized in double layer roofing forming machines represent a cutting-edge solution in the roofing industry. Their blend of strength, aesthetic appeal, and energy efficiency makes them an ideal choice for a variety of construction projects, ensuring long-lasting performance and contributing to sustainable building practices.