The Evolution and Impact of IBR Making Machines

The construction industry is continuously evolving, seeking efficient, cost-effective solutions to meet the growing demands of urbanization and infrastructure development. One notable innovation in this field is the Interlocking Brick (IBR) making machine. This invention not only revolutionizes the way bricks are produced but also contributes significantly to sustainable building practices.

Understanding IBR Manufacturing

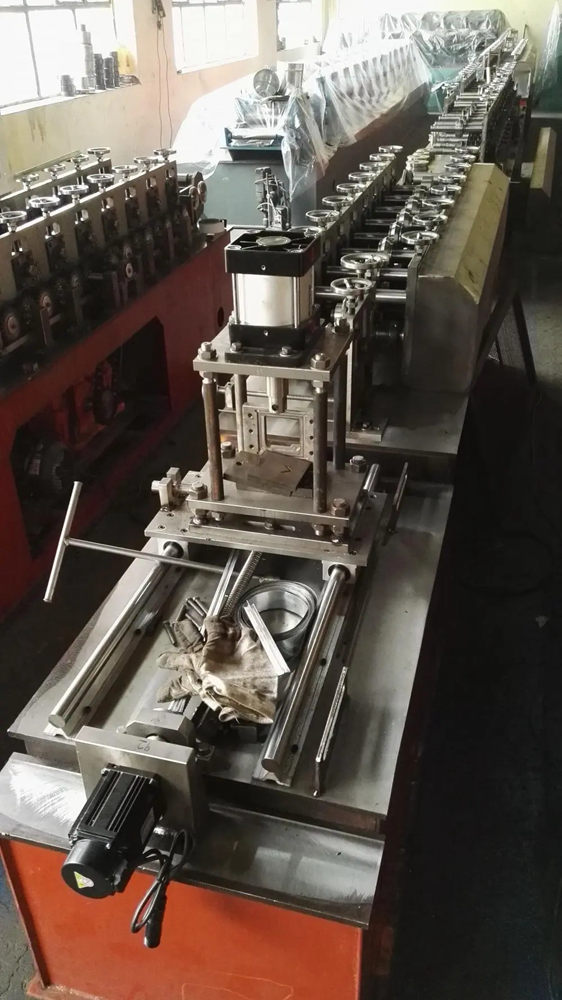

Interlocking bricks are unique because they do not require mortar for construction. Instead, their design allows them to fit snugly together, creating stable and robust structures. The IBR making machine produces these innovative bricks using a mix of soil, sand, and cement, which can be shaped into various forms and sizes to cater to diverse construction needs.

The process begins with the selection of suitable raw materials. The combination of soil and sand ensures the strength and durability of the bricks. The machine then compresses this mixture under high pressure, forming bricks that can withstand the rigors of construction and adverse weather conditions. The technological advancement in IBR making machines has allowed for the production of high-quality bricks at a much faster rate than traditional methods.

Advantages of IBR Making Machines

1. Cost-effectiveness One of the primary benefits of using IBR making machines is their cost efficiency. The materials used are often locally sourced, reducing transportation costs. Moreover, the interlocking design diminishes the amount of mortar needed, further lowering construction expenses.

2. Sustainability As the world grapples with environmental challenges, the quest for sustainable building materials has gained momentum. The use of soil-based bricks significantly reduces reliance on conventional fired bricks, which require high amounts of energy for production. By utilizing local soil and reducing waste, IBR making machines contribute to a more sustainable construction process.

3. Speed and Efficiency Traditional brick manufacturing is labor-intensive and time-consuming. In contrast, IBR making machines automate much of the process, drastically increasing production speed. This efficiency not only meets the demands of rapid urbanization but also allows builders to complete projects on time and within budget.

4. Versatility IBR making machines can adapt to various designs, producing bricks in different shapes and sizes. This versatility caters to unique architectural needs and preferences, making it easier for builders to implement creative designs without compromising strength or stability.

The Role of IBR Making Machines in Modern Construction

IBR making machines have become increasingly popular in developing countries, where rapid urban growth often outpaces traditional construction methods. These machines promote local entrepreneurship by allowing small businesses to produce bricks on-site, providing employment opportunities and supporting local economies.

Moreover, the adoption of interlocking brick technology contributes to disaster-resilient building practices. The interlocking design ensures better seismic stability, particularly crucial in earthquake-prone regions. Structures built with IBRs exhibit enhanced durability and resistance to natural disasters, empowering communities to build safer homes.

Challenges and Considerations

Despite the numerous advantages, the widespread adoption of IBR making machines is not without challenges. Initial investment costs can be a barrier for many small-scale builders. Additionally, the quality of the soil used must be carefully evaluated to ensure that the bricks produced meet necessary standards.

Furthermore, there remains a level of skepticism regarding the structural integrity of interlocking bricks compared to traditional bricks. It is essential to educate builders and consumers about the reliability and benefits of using IBRs to facilitate their acceptance.

Conclusion

The IBR making machine is a significant advancement in the construction industry, offering a sustainable, cost-effective, and efficient alternative to traditional methods. As urbanization continues to rise, the importance of innovative solutions like IBRs will only grow. By harnessing the power of technology and sustainable practices, the construction industry has the opportunity to build not just structures, but resilient communities equipped for the future.