Understanding Hydraulic Thread Rolling Machines A Comprehensive Guide to Suppliers

In the modern manufacturing landscape, precision and efficiency are paramount. Thread rolling, a method used for producing threads on cylindrical workpieces, has gained widespread attention due to its numerous advantages over traditional cutting methods. Among the various technologies employed for this process, hydraulic thread rolling machines stand out. This article delves into the significance of these machines, their operational advantages, and what to consider when selecting a supplier.

The Mechanics of Hydraulic Thread Rolling Machines

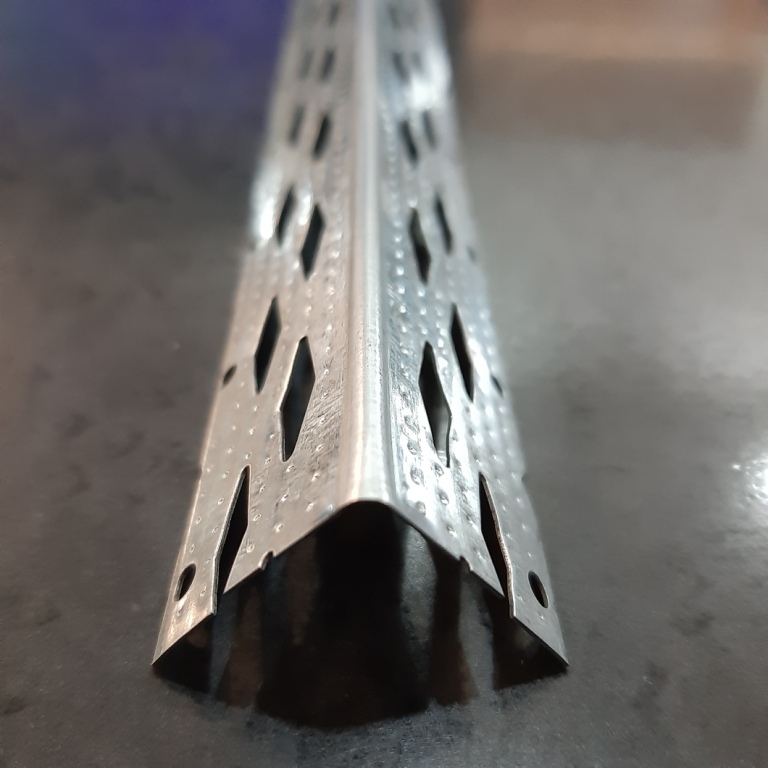

Hydraulic thread rolling machines utilize hydraulic pressure to deform the material, creating threads through a process that is both efficient and cost-effective. Unlike traditional cutting methods that remove material to form threads, thread rolling is a cold working process that reshapes the workpiece. This enables the production of stronger threads with improved fatigue resistance and surface finish.

The machinery employs steel rolls that are pressed against the workpiece, rotating the latter to form the desired thread profile. The hydraulic system provides the necessary force, allowing for the manipulation of various materials, from aluminum to high-strength steel. The result is a range of products with high dimensional accuracy and excellent surface quality.

Advantages of Hydraulic Thread Rolling

1. Enhanced Strength The cold working process increases the grain structure of the metal, resulting in threads that can support greater loads. This characteristic is particularly beneficial in applications where strength is crucial, such as in automotive and aerospace industries.

2. Improved Surface Finish Thread rolling typically produces smoother threads compared to cutting methods. This not only enhances the aesthetic quality of the products but also reduces friction, improving the performance of the threads during use.

3. Material Efficiency Since thread rolling does not remove material but rather redistributes it, there is less waste generated during manufacturing. This aspect makes it a more sustainable option in an era where companies are increasingly held accountable for their environmental impact.

4. Cost-Effectiveness Although the initial investment for hydraulic thread rolling machines may be higher than conventional machines, the overall cost of production can decrease due to lower material waste, faster production rates, and the elimination of secondary finishing processes.

Choosing the Right Supplier

Selecting the right supplier for hydraulic thread rolling machines is critical to ensuring that you achieve the desired outcomes for your production needs. Here are several factors to consider when making your choice

1. Experience and Reputation Look for suppliers with a proven track record in the industry. Research their history, customer reviews, and case studies to assess their reliability and quality of service.

2. Customization Options Every manufacturing operation is unique, and the ability to customize machines to meet specific needs can significantly impact production efficiency. A good supplier will offer machines that can be tailored to fit specific thread profiles and material requirements.

3. Technical Support and Training The complexity of hydraulic machines requires adequate support and training for operators. Ensure that the supplier offers comprehensive training programs and readily available technical support to help your team get the most out of the equipment.

4. After-Sales Service Quality after-sales service is essential for maintaining the machinery over time. Inquire about warranty policies, spare parts availability, and maintenance services to ensure long-term operational efficiency.

5. Technological Advancements The manufacturing sector is continually evolving, with new technologies emerging that can enhance productivity. Work with suppliers who are committed to innovation and can provide the latest advancements in hydraulic thread rolling technology.

Conclusion

Hydraulic thread rolling machines have revolutionized the way threads are manufactured, offering a range of benefits that improve product quality and reduce costs. When selecting a supplier, consider factors such as experience, customization capabilities, support services, and commitment to innovation. By doing so, you can ensure that your manufacturing processes are efficient, economical, and aligned with your production goals. Embracing this technology will not only enhance your product offerings but also position your business favorably in a competitive marketplace.