Understanding the pricing of hydraulic thread rolling machines requires a deep dive into several factors that can influence costs and ultimately impact purchasing decisions. These machines are vital for precise thread formation, enhancing both the efficiency and quality of manufacturing processes across various industries. Below, we delve into the intricacies of these machines' pricing and provide insights to guide an informed purchase, drawing from experience, expertise, authoritativeness, and trustworthiness.

Price Variability Factors

The price of a hydraulic thread rolling machine can vary widely due to several determinants. An essential factor is the machine's capacity, measured by the threading diameter it can handle. Machines designed for larger diameters naturally command higher prices due to the increased material and engineering precision required. Additionally, machine speed, measured in revolutions per minute (RPM), can significantly influence price. Machines with higher RPMs allow for faster processing times, which can be crucial for high-volume production lines, justifying their higher cost.

Furthermore, the degree of automation incorporated within the machine plays a pivotal role in pricing. Fully automated machines with advanced control systems and minimal operator intervention are generally more expensive. This higher cost is offset by the benefits of increased efficiency, reduced labor costs, and consistent threading quality, which are crucial for large-scale operations.

Brand Reputation and After-Sales Support

The brand and manufacturer of a hydraulic thread rolling machine significantly influence its price. Established brands known for reliability and durability tend to price their machines higher. These brands often have a robust reputation backed by years of experience and positive customer testimonials, providing an assurance of quality.

Another crucial aspect tied to brand reputation is the availability and quality of after-sales support, including training, maintenance services, and the availability of spare parts. Investing in a machine with strong after-sales support can be crucial, as breakdowns can lead to costly downtimes. The peace of mind that comes with reliable support often justifies paying a premium for machines from reputable brands.

Material and Build Quality

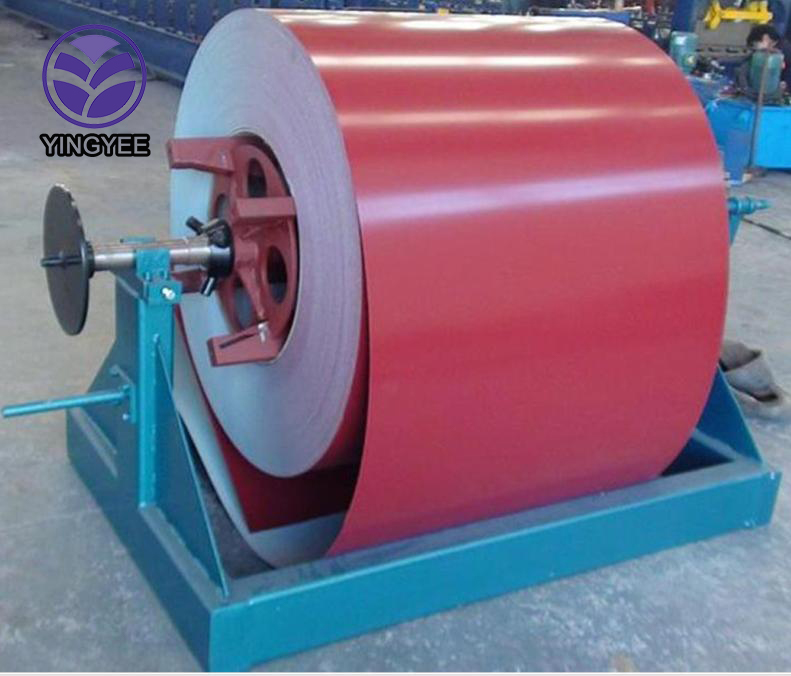

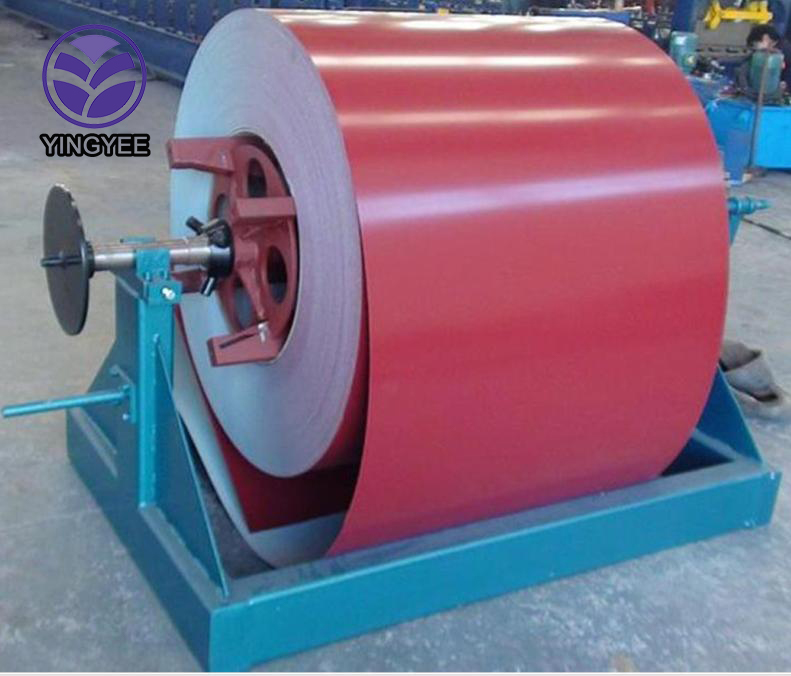

hydraulic thread rolling machine price

The materials used in constructing the machine also affect its price. Machines built with high-grade steel and durable components not only ensure longevity and consistent performance but also have a higher upfront cost. These materials are essential for minimizing wear and tear over time, leading to reduced maintenance costs in the long run.

Market Dynamics and Economic Conditions

It’s essential to consider the broader economic environment when evaluating prices. Factors such as raw material costs, technological advancements, and supply chain efficiencies can influence pricing strategies in the industry. In periods of economic stability, prices may remain relatively constant, whereas during economic unrest or high inflation periods, prices might increase due to rising production costs.

Investment Considerations

When assessing whether to invest in a hydraulic thread rolling machine, consider the total cost of ownership rather than just the initial purchase price. This includes maintenance, energy consumption, expected lifespan, and potential productivity gains. Evaluating these factors can provide a more comprehensive understanding of the machine’s value proposition.

Conclusion

Navigating the pricing landscape of hydraulic thread rolling machines involves a careful consideration of various factors, including machine specifications, brand reputation, material quality, and market conditions. Potential buyers are encouraged to not only focus on the upfront cost but to also weigh the long-term benefits and savings. By considering these factors, one can make a well-informed investment that enhances production capabilities and ensures operational efficiency.