Hydraulic Thread Rolling Machine Revolutionizing Precision Manufacturing

In the world of manufacturing, precision and efficiency are paramount. Among the various techniques employed to achieve these attributes, thread rolling has emerged as a significant process. A hydraulic thread rolling machine is at the forefront of this technology, providing manufacturers with a reliable method for producing high-quality threaded components.

What is Thread Rolling?

Thread rolling is a cold-forming process used to create external threads on a workpiece. Unlike traditional cutting methods that remove material, thread rolling displaces the material, resulting in threads that possess greater strength and a finer finish. This technique reduces the risk of metal fatigue, making the components more durable under stress.

The Role of Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines utilize hydraulic power to apply the pressure necessary for the thread-forming process. These machines convert hydraulic energy into rotary motion, allowing them to apply force efficiently and uniformly across the workpiece. The advantages of hydraulic machines over mechanical ones include better control, smoother operation, and the ability to handle a wider range of materials and shapes.

Key Features of Hydraulic Thread Rolling Machines

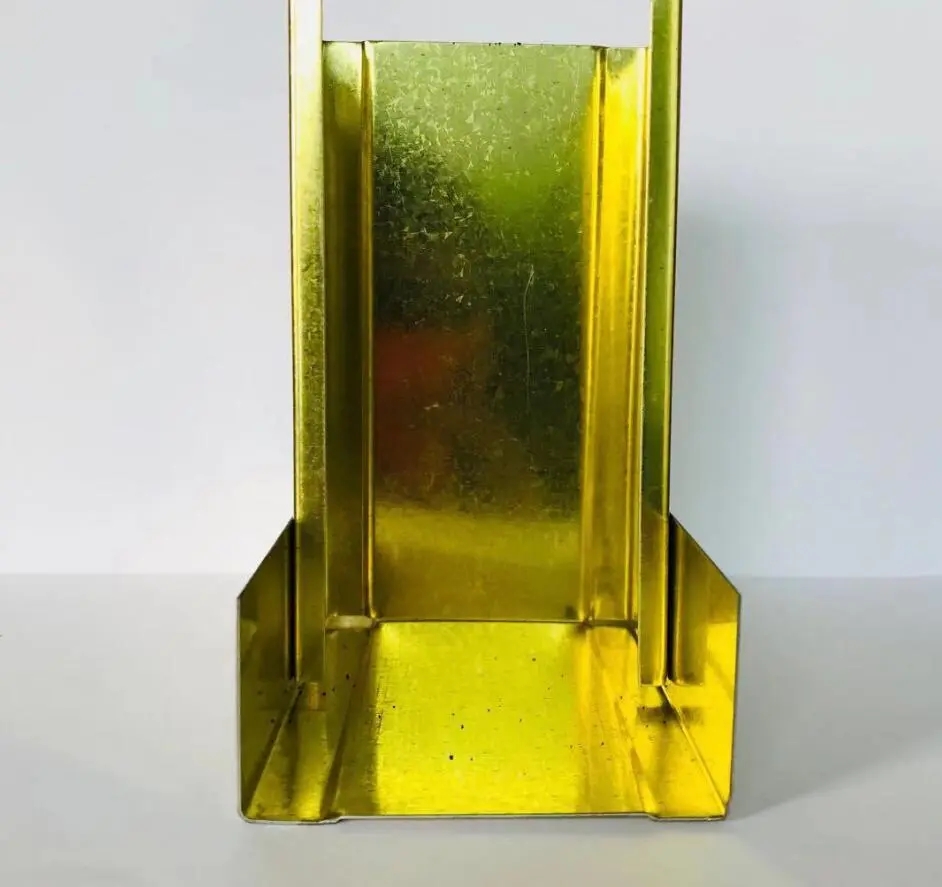

1. Hydraulic System The hydraulic system is the heart of the machine, offering adjustable pressure and stroke length. This adaptability allows manufacturers to work with various materials, from softer metals like aluminum to harder alloys like steel, ensuring versatility in production.

2. Precision Control Modern hydraulic thread rolling machines are equipped with advanced control systems, including numerical control (NC) and computer numerical control (CNC). These systems facilitate precise adjustments to speed, pressure, and feed rates, ensuring that each threaded component meets stringent specifications.

3. Quick Setup and Operation One of the significant advantages of hydraulic thread rolling machines is their quick setup time. Operators can easily switch between different thread sizes and pitches, contributing to increased production efficiency. With fewer tool changes required compared to cutting methods, downtime is minimized.

4. High Production Rates The cold-forming nature of thread rolling allows for high production rates. Since the process does not involve cutting, it generates less waste material, maximizing yield and reducing costs. Manufacturers can produce thousands of components with consistent quality, making it ideal for high-volume applications.

5. Enhanced Surface Finish The rolling process results in threads with superior surface finishes compared to traditional cutting methods. This is particularly important in industries where component appearance and function are critical, such as automotive and aerospace manufacturing.

Applications of Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines find applications across various industries. In the automotive sector, they are used to produce bolts, screws, and other fasteners that are critical for vehicle assembly. The aerospace industry benefits from these machines in the production of high-strength components that must withstand extreme conditions. Additionally, the construction and energy sectors utilize thread rolling for manufacturing parts that require enhanced durability and corrosion resistance.

Future Trends in Thread Rolling Technology

As technology continues to advance, hydraulic thread rolling machines are expected to evolve alongside it. Innovations such as artificial intelligence (AI) and machine learning are beginning to play a role in optimizing production processes. Smart machines equipped with sensors may soon be able to monitor performance in real-time, automatically adjusting parameters to ensure optimal results.

Moreover, as sustainability becomes increasingly important in manufacturing, thread rolling machines will likely incorporate eco-friendly practices. This includes using energy-efficient hydraulic systems and reducing waste through improved process design.

Conclusion

Hydraulic thread rolling machines represent a significant advancement in precision manufacturing. With their ability to produce high-quality threaded components efficiently and economically, they have become indispensable in various industries. As technology progresses and demand for high-performance parts continues to grow, these machines will play a crucial role in shaping the future of manufacturing. The combination of innovation, efficiency, and precision makes hydraulic thread rolling machines an essential asset for any manufacturing operation looking to thrive in a competitive marketplace.