Understanding the Hydraulic Automatic CZ Purlin Touch Screen Forming Machine

The construction industry is experiencing rapid development, leading to the increasing demand for innovative machinery that can optimize production processes. Among these advancements is the hydraulic automatic CZ purlin touch screen forming machine, a cutting-edge solution designed to enhance the manufacturing of purlins efficiently and effectively.

What is a CZ Purlin?

Before diving into the machine's features, it’s essential to understand what a CZ purlin is. Purlins are horizontal structural members used to support roofing and walls in construction projects. The C and Z shapes of purlins are named after their respective cross-sectional profiles, which give them specific load-bearing properties. These shapes make CZ purlins ideal for various applications, including metal buildings, warehouses, and other industrial structures, due to their strength and ease of installation.

The Role of the Touch Screen Forming Machine

The hydraulic automatic CZ purlin forming machine is designed to produce purlins seamlessly and with high precision. One of its standout features is the touch screen interface, which allows operators to easily control and monitor the machine's functions. This user-friendly control panel simplifies operations, making it accessible even for those with minimal technical expertise.

With the touch screen, users can select various purlin sizes, thicknesses, and lengths, adjusting settings on the fly based on production needs. This adaptability is crucial in a dynamic market where customization and quick turnaround times are vital for business success.

Hydraulic System Advantages

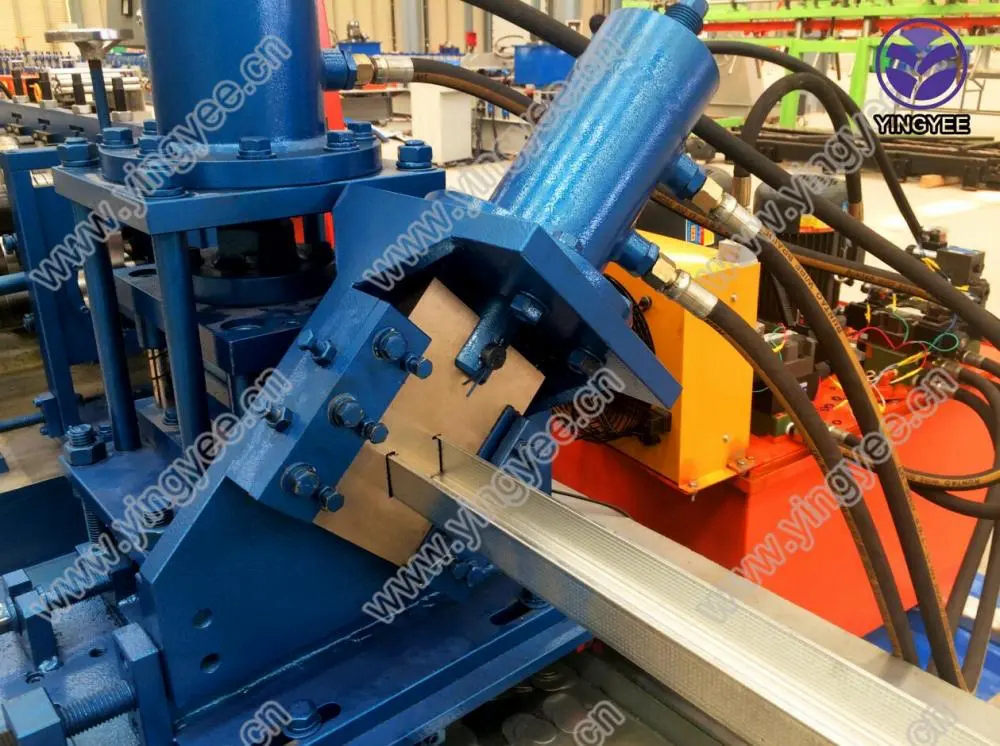

The hydraulic system in this machine plays a significant role in its efficiency and effectiveness. Hydraulic drives offer numerous advantages, including powerful force application, smooth operation, and enhanced energy efficiency. These systems enable the machine to achieve precise bending and shaping of metal sheets, resulting in high-quality purlins with minimal waste material.

Furthermore, hydraulic machines often require less maintenance compared to mechanical systems, which reduces operational downtime and contributes to a more effective production line. The robust hydraulic components ensure longevity and reliability, making the investment in such a machine worthwhile for manufacturers.

The Efficiency of the Automatic Feature

Automation is a game-changer in manufacturing processes. The hydraulic automatic CZ purlin forming machine is built with an automatic feeding and cutting system, which drastically reduces manual labor and increases productivity. With this feature, the machine can continuously produce purlins without the need for constant human intervention, allowing for higher output rates and reduced labor costs.

Integrated with advanced sensors, the machine can also detect material consistency and feed accordingly, further optimizing the production process and ensuring that each purlin meets strict quality specifications.

Conclusion

The hydraulic automatic CZ purlin touch screen forming machine represents a significant advancement in the field of construction machinery. With its user-friendly interface, powerful hydraulic capabilities, and automated features, it enhances manufacturing efficiency and product quality. As the construction industry continues to evolve, investing in such advanced machinery will be imperative for companies looking to remain competitive, meet customer demands, and produce high-quality structures that stand the test of time.

In summary, this machine not only streamlines the production of essential building materials but also paves the way for a more innovative and efficient future in construction. As technology continues to advance, the potential for further improvements and enhancements in such machinery is limitless, promising exciting developments for manufacturers and builders alike.