The Hydraulic Automatic CZ Purlin Touch Screen Forming Machine Revolutionizing Steel Fabrication

In the realm of modern construction and structural engineering, efficiency and precision are paramount. The hydraulic automatic CZ purlin touch screen forming machine has emerged as a game-changer in the fabrication of purlins, which are vital components used in the construction of steel buildings. These machines combine advanced technology with user-friendly interfaces to enhance productivity and streamline operations.

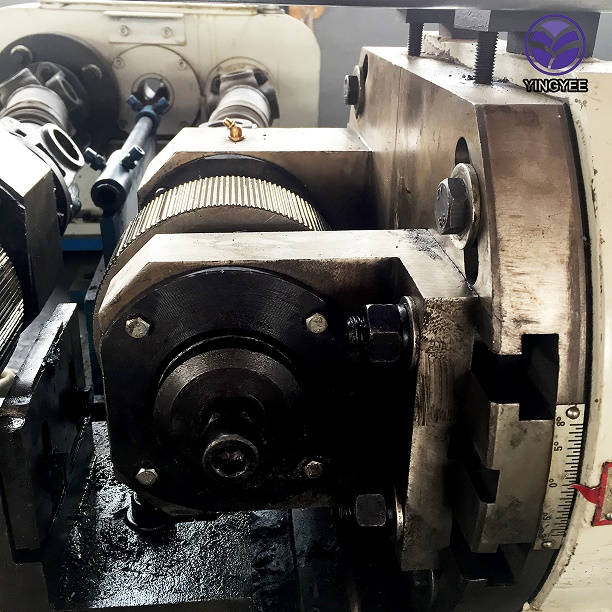

At the core of this innovative equipment is its hydraulic system, which provides exceptional strength and stability during the forming process. Unlike traditional machines that rely on mechanical systems, the hydraulic system ensures smooth operation and precise control, allowing for the production of high-quality steel purlins with various specifications. This adaptability is crucial as the demand for customized steel components continues to rise in the construction industry.

One of the standout features of the hydraulic automatic CZ purlin machine is its touch screen interface. This modern control system simplifies operations, enabling operators to easily adjust settings and monitor the forming process in real-time. The touch screen display allows for intuitive interaction, reducing the learning curve for new operators and minimizing the risk of human error. Users can input specific dimensions and requirements directly, making the transition from design to production seamless and efficient.

Furthermore, this machine is capable of producing both C and Z shaped purlins - hence the term CZ purlin. This flexibility makes it an ideal choice for various construction applications, including roofing, wall framing, and other structural support systems. The ability to switch between different shapes without significant downtime enhances production capacity and allows manufacturers to meet diverse client needs.

Another significant advantage of the hydraulic CZ purlin forming machine is its automated processes. The integration of automation not only speeds up production but also ensures consistent quality across all products. This is particularly important in construction, where structural integrity is non-negotiable. Automatic cutting, stacking, and even packaging systems mean that once the fabrication is set in motion, operators can focus on other essential tasks without constant supervision.

Moreover, the incorporation of energy-efficient hydraulic systems helps reduce operational costs, making the investment in such machinery economically viable for fabricators. The durability of hydraulic components also means less maintenance and longer operational life, further driving down costs over time.

As the construction industry continues to evolve, the demand for innovative solutions becomes increasingly vital. The hydraulic automatic CZ purlin touch screen forming machine embodies the convergence of technology and practicality, offering a robust solution for steel fabrication. Its advanced features, including hydraulic power, user-friendly touch screen controls, and versatile production capabilities, position it as an invaluable tool for manufacturers seeking to enhance efficiency and quality in their operations.

In conclusion, the hydraulic automatic CZ purlin touch screen forming machine is setting new standards in the construction industry. By combining cutting-edge technology with user-friendly design, it not only boosts productivity but also ensures that high-quality steel components are produced to meet the ever-growing demands of modern construction. As this technology continues to advance, it will undoubtedly play a crucial role in shaping the future of structural engineering.