Horizontal Large Span Roll Forming Machine An Overview

In the realm of modern manufacturing, roll forming has emerged as a pivotal process for creating a variety of metal products with consistent quality and precision. Among the various types of roll forming machines available, the horizontal large span roll forming machine stands out due to its ability to produce wide components that cater to the diverse needs of industries such as construction, automotive, and aerospace.

What is a Horizontal Large Span Roll Forming Machine?

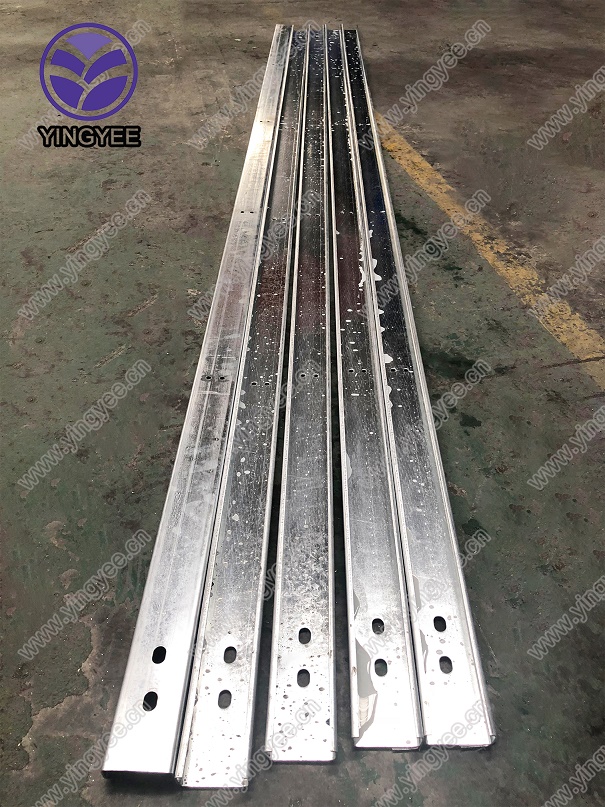

A horizontal large span roll forming machine is specifically designed to shape metal sheets into long channels, beams, and other components with large spans. Unlike traditional vertical roll forming machines, which typically work with narrower products, horizontal machines can handle wider strips of metal, making them ideal for producing materials like roofing sheets, floor decking, and structural frames.

Key Features and Advantages

1. Robust Structure One of the defining features of horizontal large span roll forming machines is their robust construction. These machines are built to withstand high levels of mechanical stress while maintaining stability and precision throughout the forming process.

2. Wide Product Range The horizontal design allows for the production of a wider range of profiles. This versatility is crucial for industries that require customized solutions for different applications, from heavy-duty construction beams to lightweight panels.

3. Efficiency and Speed Modern horizontal roll forming machines are equipped with advanced technologies that enhance their operational efficiency. Automated feeding systems, high-speed rollers, and precision controls all contribute to faster production rates while ensuring high-quality outputs.

4. Energy Savings The design and operation of these machines often incorporate energy-saving mechanisms. By optimizing the process and reducing waste during forming, manufacturers can achieve significant cost savings while also adhering to environmental standards.

5. Ease of Operation With user-friendly interfaces and automated controls, horizontal large span roll forming machines are relatively easy to operate. This reduces the need for extensive training and allows for quick adjustments during production runs.

6. Durability and Maintenance Built with high-quality materials and precision engineering, these machines require minimal maintenance and are designed to last longer. This durability translates into lower operational costs over time.

Applications of Horizontal Large Span Roll Forming Machines

The applications of horizontal large span roll forming machines are vast and varied. In the construction industry, they are utilized to create structural components for buildings, bridges, and other infrastructure projects. In the automotive sector, these machines can produce components such as chassis and body panels. Additionally, they are used in manufacturing roofing sheets and wall panels, which are essential for both residential and commercial buildings.

Conclusion

The horizontal large span roll forming machine is a game-changer in the manufacturing sector, combining efficiency, versatility, and precision. As industries continue to evolve and demand more customized solutions, the importance of such advanced machinery will only grow. Investing in a horizontal large span roll forming machine not only enhances production capabilities but also positions manufacturers to meet the challenges of a competitive marketplace. As technology advances further, these machines will likely incorporate even more sophisticated features, further revolutionizing the roll forming process.