Understanding Highway Guardrail Making Machines A Key to Road Safety

Highway safety is a paramount concern in modern transportation, and one of the critical components ensuring this safety is the guardrail. These barriers are designed to prevent vehicles from veering off the road and to minimize damage during collisions. Behind the production of these essential safety features lies a vital piece of machinery the highway guardrail making machine.

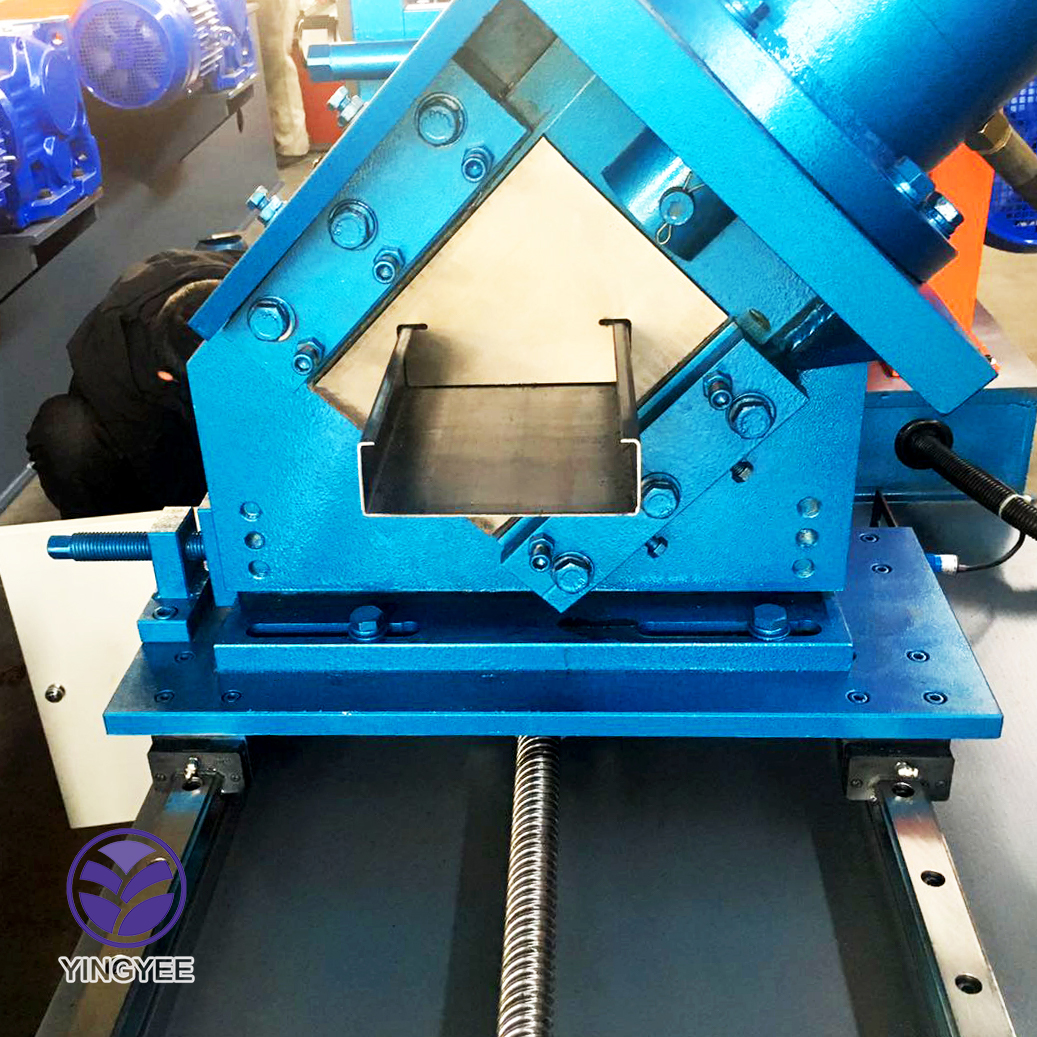

What is a Highway Guardrail Making Machine?

A highway guardrail making machine is an industrial device specifically designed to fabricate guardrails from various materials, primarily steel. These machines are equipped to perform processes such as cutting, bending, and welding to produce the necessary components of guardrails. Their advanced technology ensures that the products meet stringent safety standards while maintaining efficiency in production.

The Manufacturing Process

The manufacturing process typically begins with high-quality raw materials. Steel coils are commonly used due to their strength and durability. The guardrail making machine first unrolls and cuts these coils into manageable lengths. Each length is then shaped and bent into the required profile. This profile often includes a wave-like pattern that helps absorb impact and redirect vehicles safely back onto the road.

Once the bending is accomplished, the machine engages in welding. Automated welding processes ensure that joints are robust and resistant to wear. Finally, the guardrails undergo finishing processes, which may include galvanizing to protect against corrosion. Quality control checks are crucial at every stage to ensure that the guardrails are capable of withstanding the various forces they might encounter in real-world scenarios.

Importance of Quality and Standards

The effectiveness of guardrails directly correlates with their quality. High-quality guardrails save lives, and the machines that create them must adhere to rigorous safety standards set by government regulations. Manufacturers often work with engineering teams to develop guardrails that respond effectively to specific crash test criteria. This collaboration ensures that each product not only meets but exceeds safety expectations.

Technological Advancements

Recent advancements in technology have transformed highway guardrail making machines. Automation and robotics have greatly increased precision and efficiency, reducing the likelihood of human error. Additionally, computer-aided design (CAD) software allows for customizable guardrail designs, catering to specific geographical and environmental conditions. This adaptability is crucial, as different regions may require different types of guardrails based on their traffic patterns and accident statistics.

Sustainability in Production

As environmental concerns continue to grow, manufacturers are increasingly focusing on sustainable practices. Modern guardrail making machines can often utilize recycled materials, contributing to a circular economy. Moreover, energy-efficient technologies are being incorporated to reduce the carbon footprint associated with production processes.

Conclusion

Highway guardrail making machines play a crucial role in the safety of our roadways. By utilizing advanced technology and adhering to strict quality standards, these machines help ensure that the guardrails produced can withstand the rigors of everyday traffic and protect lives. As the industry evolves, so too will the machines and practices that create these vital safety barriers, leading to even safer roads for everyone. The intersection of technology, engineering, and safety exemplifies the importance of investing in quality machinery to safeguard our highways.