The Importance of Highway Guardrail Machines in Modern Infrastructure

Highway guardrails are essential components of road safety systems, designed to protect vehicles from collisions with obstacles and to prevent vehicles from veering off the road. The manufacturing of highway guardrails has evolved significantly over the years, thanks in large part to the development of specialized machinery dedicated to their production. This article explores the importance of highway guardrail machines, their functionality, and the impact they have on modern infrastructure.

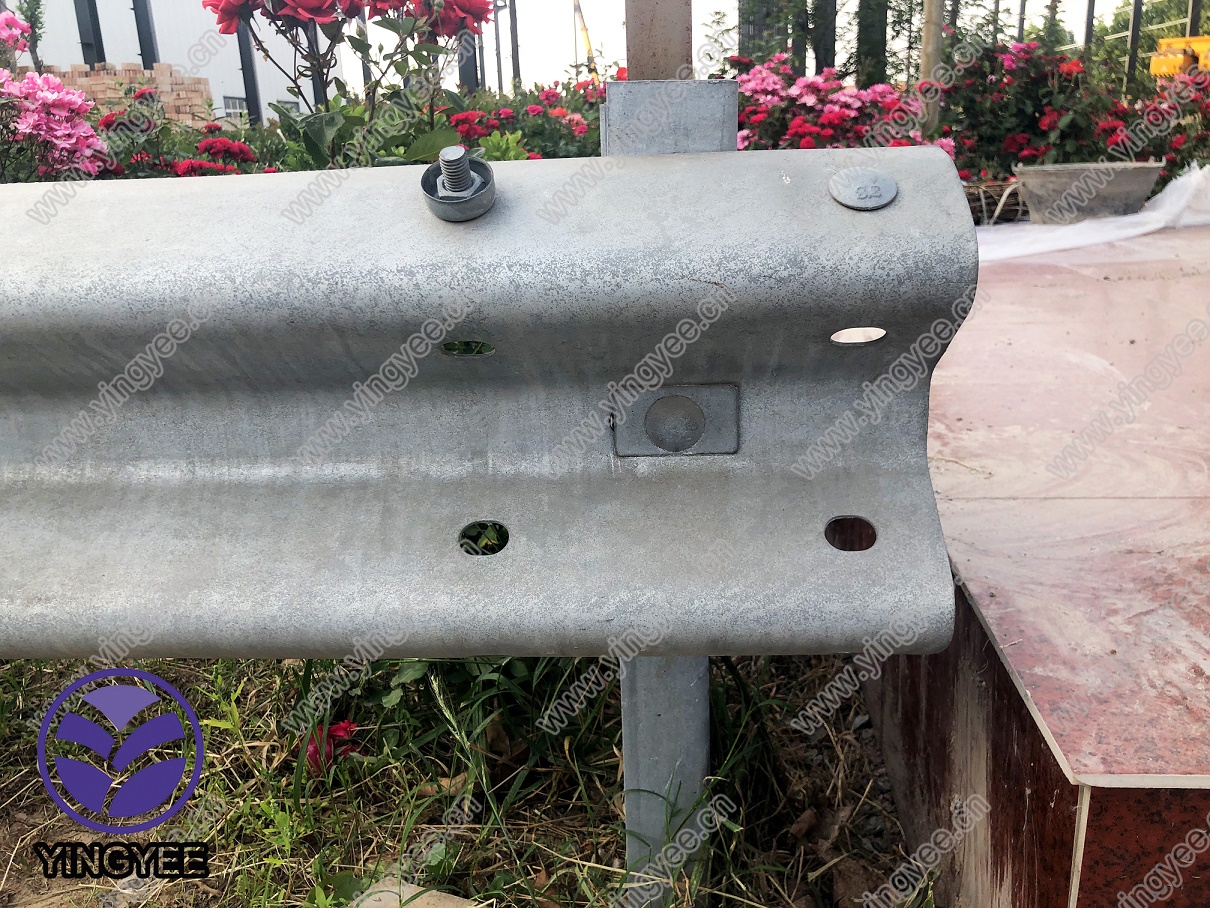

Highway guardrail machines are specifically engineered to manufacture guardrails with precision and efficiency. These machines can perform various tasks, including cutting, shaping, and welding materials to create durable and effective guardrails. The use of automated machinery in guardrail production not only speeds up the manufacturing process but also ensures consistent quality and adherence to safety standards, which are critical for public safety.

One of the primary advantages of highway guardrail machines is their ability to produce guardrails in large quantities

. This mass production capability is vital, especially during road construction projects that require extensive safety measures. By utilizing advanced technology, manufacturers can streamline the production process, reducing lead times and ensuring that projects stay on schedule. Additionally, the automated systems reduce the likelihood of human error, which can lead to costly mistakes or failures in safety performance.

The materials used in guardrail production typically include steel and aluminum, both known for their strength and durability. Highway guardrail machines are designed to handle these materials effectively, ensuring that the final products can withstand significant impact forces. This resistance is crucial in protecting drivers and passengers from accidents, minimizing injuries, and saving lives.

Furthermore, highway guardrail machines contribute to the ongoing development of innovative designs and technologies. Manufacturers are continuously improving guardrail systems to enhance safety features, including energy absorption mechanisms that reduce the impact forces during collisions. This innovation is supported by the capabilities of modern machinery, which allows for experimentation with new materials and designs that can further improve the effectiveness of guardrails.

The environmental impact of highway guardrail machines is also an important consideration. Many manufacturers are now focused on sustainability, seeking methods to recycle materials and reduce waste during production. Advances in technology allow for the production of guardrails that are not only safer but also more environmentally friendly, aligning with global efforts to protect our planet.

In conclusion, highway guardrail machines play a crucial role in the manufacturing of road safety equipment. Their ability to produce high-quality guardrails efficiently and in large volumes enhances road safety for everyone. As technology continues to advance, so too will the capabilities of these machines, leading to even safer and more effective highway systems. Investing in the latest guardrail manufacturing technologies is essential for maintaining and improving the safety of our roads and highways, ensuring that they meet the demands of a growing population and evolving transportation needs.