The Essential Role of Highway Fence Guardrail Roll Forming Machines

In today's rapidly developing world, the safety and security of roadways have become a priority for governments and construction companies alike. Among the various safety measures employed on highways, guardrails play an indispensable role in protecting vehicles from veering off the road and reducing the severity of accidents. As the demand for effective road safety solutions continues to rise, advanced machinery has been developed to enhance the production of fence guardrails. One such innovation is the highway fence guardrail roll forming machine.

Understanding Roll Forming Technology

Roll forming is a manufacturing process that involves shaping metal sheets or strips into specific profiles using a series of rollers. This process is particularly effective for producing long lengths of uniform shapes, which is essential for highway guardrails. The advantages of roll forming include high efficiency, minimal waste, and the ability to produce complex shapes with precise specifications. A highway fence guardrail roll forming machine uses this technology to create guardrails that meet stringent safety standards while ensuring durability and longevity.

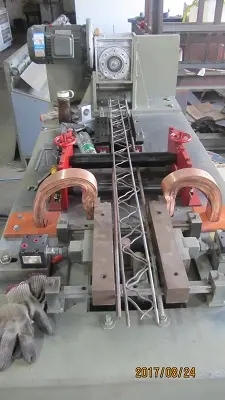

The Components of a Roll Forming Machine

A typical highway fence guardrail roll forming machine consists of several key components

1. Feed Mechanism This part feeds metal strips into the rollers at a controlled rate, ensuring a consistent and uninterrupted production process.

2. Roll Forming Stations These stations house the rollers that shape the metal. Each station is designed to perform a specific part of the shaping process, gradually transforming flat metal strips into the desired guardrail profile.

3. Cutting Unit Once the guardrails have been formed, they need to be cut to specific lengths. The cutting unit can operate either manually or automatically, depending on the machine's design.

4. Control Panel Modern machines come with sophisticated control panels that allow operators to manage the entire production process easily. This includes adjusting the speed, thickness, and profile of the guardrails being produced.

5. Stacking System After the guardrails are cut, a stacking system is used to neatly organize the finished products for easy transportation and installation.

Advantages of Highway Fence Guardrail Roll Forming Machines

1. High Efficiency These machines have the ability to produce large quantities of guardrails in a relatively short time, helping to meet the increasing demand for road safety products.

2. Customization With advanced technology, manufacturers can easily adjust the machine settings to create various guardrail profiles, allowing for customization based on specific project requirements.

3. Quality Assurance The precision of roll forming ensures that each guardrail meets quality standards. This reduces the likelihood of defects and increases the safety of the final product.

4. Cost-Effectiveness While the initial investment in a roll forming machine can be significant, the efficiency and reduction in waste lead to long-term cost savings for manufacturers. Additionally, roll forming reduces labor costs, as the process can often be automated.

5. Durability Guardrails produced by roll forming are designed to withstand harsh environmental conditions. The use of high-quality materials ensures longevity, thereby enhancing road safety over time.

Conclusion

The highway fence guardrail roll forming machine represents a critical advancement in roadway safety technology. As it continues to evolve with modern engineering practices, it plays a vital role in ensuring that highways and roads remain safe for all users. By producing durable and reliable guardrails, manufacturers contribute significantly to accident prevention and the overall improvement of highway safety.

As nations invest in infrastructure and prioritize road safety, the importance of automated machinery like the highway fence guardrail roll forming machine will only grow. Policymakers, manufacturers, and engineers must collaborate to embrace these innovations, ensuring that safety standards are met and that the roads remain safe for future generations. In this ever-evolving landscape, the commitment to quality and innovation in guardrail production will define the future of highway safety.