High-Speed Roller Door Panels Forming Machine Revolutionizing Efficiency in Industrial Applications

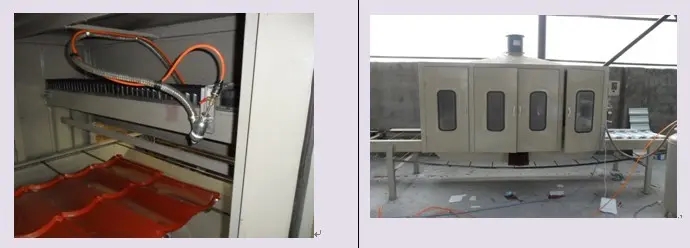

In today's fast-paced industrial landscape, efficiency and productivity are paramount. One of the key advancements contributing to this is the high-speed roller door panels forming machine. This innovative piece of equipment is designed to streamline the production of roller door panels, which are widely used in warehouses, factories, garages, and other commercial spaces.

The high-speed roller door panels forming machine is engineered to enhance production efficiency by significantly reducing the time required to manufacture door panels. Traditional methods often involve labor-intensive processes that are not only time-consuming but also prone to human error. In contrast, these advanced machines employ automated systems that ensure precision and consistency, resulting in high-quality panels produced at an impressive rate.

One of the standout features of these forming machines is their versatility. They can accommodate various materials, including steel, aluminum, and fiberglass, allowing manufacturers to cater to a diverse range of client needs. The machine can be easily adjusted to create panels of different thicknesses, sizes, and designs, ensuring that businesses can produce custom solutions according to market demand and customer preferences.

Moreover, the machine’s design incorporates advanced technology such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), enabling operators to monitor and control the production process effortlessly. This not only enhances operational efficiency but also allows for real-time adjustments to optimize output based on specific requirements. With enhanced data tracking capabilities, manufacturers can analyze production metrics, identify areas for improvement, and ultimately increase overall productivity.

Another significant advantage of the high-speed roller door panels forming machine is its contribution to waste reduction. Traditional manufacturing processes often result in excess scrap material due to improper cuts or inaccurate measurements. However, with its precision engineering, this machine minimizes waste by ensuring that every cut is accurate, maximizing the use of raw materials and reducing costs.

Furthermore, the high-speed roller door panels forming machine promotes a safer working environment. By automating the heavy lifting and moving of materials, these machines reduce the risk of workplace accidents associated with manual handling. Operators can work more safely and efficiently, focusing on monitoring the machinery rather than performing strenuous physical tasks.

In conclusion, the high-speed roller door panels forming machine is a game-changer for industries reliant on efficient door panel production. With its ability to increase output, reduce waste, and enhance safety, it stands out as a vital investment for manufacturers looking to improve their operational processes. As the demand for high-quality, durable roller doors continues to grow, so too does the need for advanced manufacturing solutions that can meet these demands swiftly and effectively. Investing in such technology not only paves the way for improved productivity but also positions companies at the forefront of their industry, ready to tackle the challenges of the ever-evolving market landscape.