High-Speed Roller Door Panels Forming Machine Revolutionizing Industrial Efficiency

In today’s fast-paced industrial landscape, efficiency and durability are paramount. One of the innovations contributing to this need is the high-speed roller door panels forming machine. This advanced technology not only streamlines the manufacturing process but also enhances the quality of the products, making it a critical investment for businesses aiming to optimize their operations.

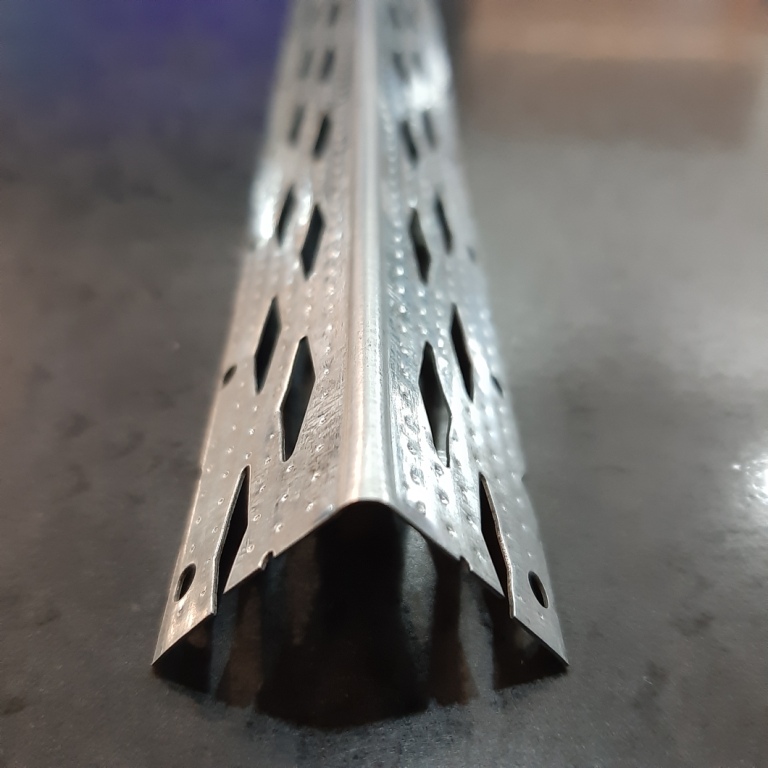

The high-speed roller door panels forming machine is designed to produce roller door panels with remarkable speed and precision. These machines utilize cutting-edge forming technology that allows for rapid production without compromising on quality. The primary function of these machines is to transform raw materials, typically steel or aluminum, into fully functional door panels. By employing automated processes, manufacturers can significantly reduce labor costs and minimize human error, leading to a more efficient production line.

One of the standout features of high-speed roller door panels forming machines is their capability to produce a variety of panel sizes and styles to meet diverse market demands. These machines can be easily adjusted to create different profiles and thicknesses of panels, offering manufacturers greater flexibility. This adaptability is crucial in an era where custom solutions are increasingly sought after by clients. Whether it's for commercial, industrial, or residential applications, these machines can cater to specific requirements, helping businesses maintain a competitive edge.

Moreover, the efficiency of these machines extends to their energy consumption. Modern high-speed forming machines are engineered with energy-saving technologies, making them not only cost-effective but also environmentally friendly. This is an important consideration for manufacturers looking to reduce their carbon footprint and comply with increasingly stringent environmental regulations. The integration of energy-efficient motors and intelligent control systems allows for a reduced energy load while maximizing output, fostering sustainable manufacturing practices.

Quality control is yet another area where high-speed roller door panels forming machines excel. Equipped with advanced sensors and automated inspection systems, these machines ensure that every panel produced meets stringent quality standards. By detecting defects in real time, manufacturers can minimize waste and ensure that only the best products reach the market. This commitment to quality can enhance brand reputation and customer satisfaction, further solidifying a company’s position in a competitive industry.

Furthermore, the overall design of high-speed roller door panels forming machines facilitates ease of use and maintenance. With user-friendly interfaces, operators can easily manage the production process, making it accessible even for those with minimal technical expertise. Regular maintenance is simplified, which reduces downtime and enhances productivity. As a result, businesses can focus on growth rather than being bogged down by machinery issues.

In conclusion, the high-speed roller door panels forming machine represents a significant advancement in manufacturing technology. By enhancing speed, flexibility, energy efficiency, and quality control, these machines are reshaping how businesses approach production. Investing in such technology not only contributes to operational efficiency but also positions companies to meet the evolving demands of the market. As industries continue to innovate, the role of high-speed forming machines will undoubtedly become more central, paving the way for a future defined by excellence in manufacturing.