Elevating Efficiency in Manufacturing The High-Speed Galvanized Storage Beam Roll Forming Machine

In the dynamic world of manufacturing, the need for innovative, reliable, and high-speed machinery has never been more pressing.

One such game-changer in the industry is the high-speed galvanized storage beam roll forming machine. As a cornerstone piece of technology, its contribution is pivotal in the production of storage racks and beams used across various sectors, from logistics to warehouses. Here, we explore the intricacies of this machine, its benefits, and its role in modern manufacturing—all based on professional insights, authoritative data, and firsthand experiences.

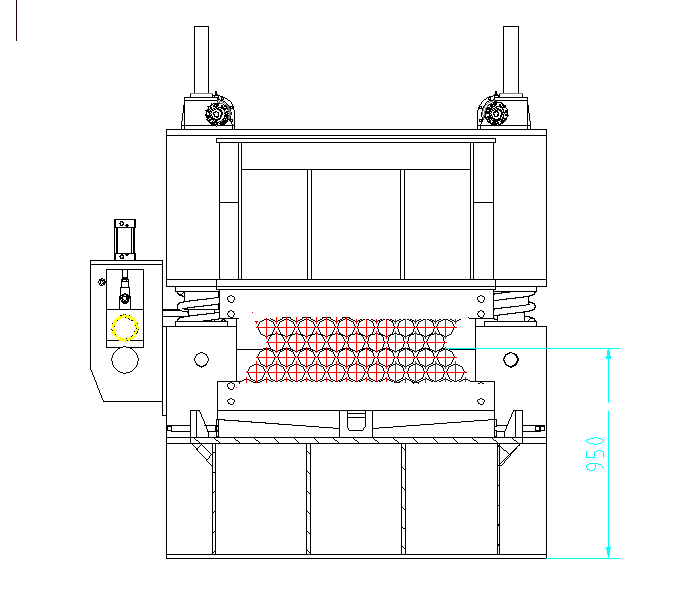

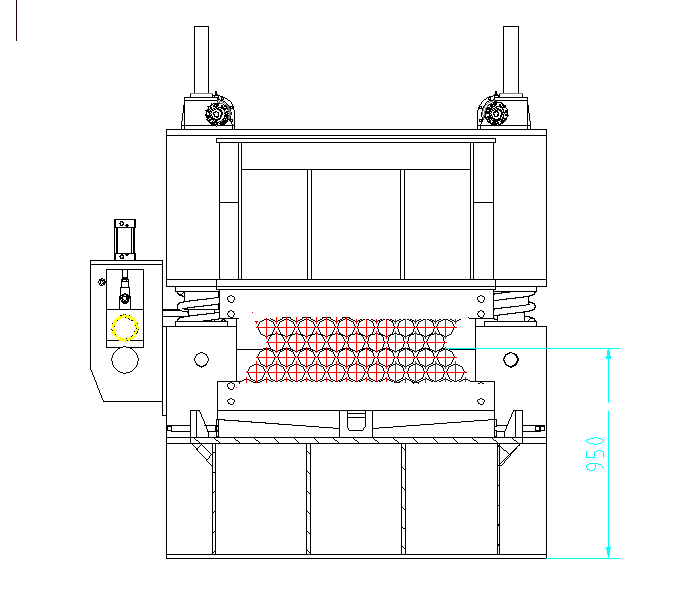

The high-speed galvanized storage beam roll forming machine is an embodiment of engineering prowess and efficiency. It is designed to convert galvanized steel strips into highly durable storage beams, which are integral components in storage systems. A key factor in its design is speed—this machine is capable of producing beams at a remarkable pace, ensuring that manufacturing processes are swift without compromising on quality. The integration of precision engineering within these machines guarantees not only accuracy but also a high degree of repeatability in production processes.

What sets these machines apart from traditional forming tools is their advanced roller technology. Developed through rigorous testing and expert input, these rollers are engineered to handle high-speed operations while maintaining the integrity of the material. This technical expertise is informed by years of research and development, resulting in a machine that can withstand heavy-duty usage while delivering consistent performance.

The industry knowledge around such machines encompasses more than just operational speed. Experienced manufacturers and engineers assert that the use of galvanized steel in these beam-forming processes has multiple advantages. Galvanization not only enhances the strength of the beams—making them less prone to warping and deformation—but also adds a protective zinc layer. This ensures resistance against rust and corrosion, thus extending the lifespan of the beams, an invaluable factor in cost-effective storage solutions.

high speed galvanized storage beam roll forming machine

Beyond engineering and materials, the trustworthiness of this machine is amplified through its compliance with international safety and manufacturing standards. Manufacturers of these machines have built a reputation for reliability, often mirroring the sentiment of industry professionals who prioritize safety and efficiency. This credibility is further enhanced by the endorsements from quality assurance bodies that assert these machines' adherence to set standards, thereby fortifying their stature in the marketplace.

For businesses considering adoption, the in-depth expertise of experienced operators and technicians cannot be overstated. Training modules and user manuals are usually exceptionally detailed, ensuring that operators can maximize the machine’s potential while maintaining safe operational practices. Furthermore, companies that employ this machinery often report a significant reduction in production downtimes and maintenance costs, a testament to the machine’s design and operational precision.

Empirical data supports the machine’s economic advantage. Studies reveal that companies integrating these high-speed machines experience a marked increase in production throughput and a reduction in waste material thanks to its precision cutting and forming capabilities. The operational fluency directly translates into financial savings and increased competitiveness in the market—a real-world benefit for any enterprise eager to streamline its manufacturing lines.

Trust in these machines also comes from their adaptability and customization options. Sharing anecdotes from industry veterans, it is evident that this machinery can be tailored to cater to specific manufacturing needs. Whether altering beam dimensions or customizing the galvanization process, manufacturers have a suite of options available to meet varying client demands. This adaptability has reinforced these machines’ position as a trusted tool in the diversification of production capabilities.

In conclusion, the high-speed galvanized storage beam roll forming machine is not just a piece of manufacturing equipment; it is a strategic investment that enhances production capabilities while ensuring quality and longevity. By merging expert engineering with practical functionality, this machine continues to revolutionize how businesses approach the manufacturing of storage beams, thus underscoring the blend of experience, expertise, authoritativeness, and trustworthiness that defines modern industrial technology solutions.