High-Speed Galvanized Storage Beam Roll Forming Machine Revolutionizing Storage Solutions

In the ever-evolving world of manufacturing and logistics, efficiency and durability are paramount. One significant innovation in this space is the high-speed galvanized storage beam roll forming machine. This advanced piece of machinery is designed to produce galvanized storage beams with exceptional precision, speed, and reliability, vastly improving the efficiency of storage systems in various industries.

Understanding Roll Forming Technology

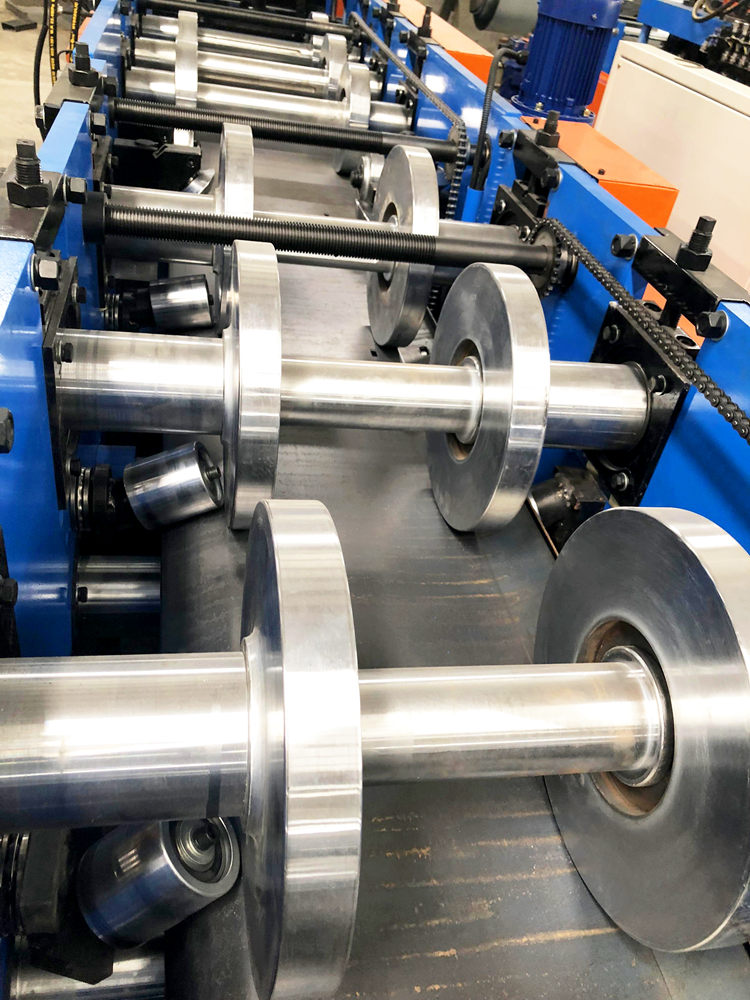

Roll forming is a continuous bending process in which a long strip of metal is passed through consecutive pairs of rollers, gradually shaping it into a desired cross-section. This technique is particularly advantageous for producing beams and other structural components since it allows for high volume production and maintains uniformity in shape and quality.

When it comes to galvanized materials, the benefits are amplified. Galvanization involves applying a protective zinc coating to steel to prevent rust and corrosion, significantly enhancing the longevity and durability of structures built with these materials. The combination of roll forming and galvanization thus creates a powerful synergy that meets the demands of modern storage needs.

Features of High-Speed Machines

High-speed galvanized storage beam roll forming machines are equipped with several advanced features that distinguish them from traditional manufacturing methods

1. Speed and Efficiency These machines are designed for rapid production, capable of producing large quantities of beams in a short time. This speed not only reduces labor costs but also shortens lead times, allowing businesses to meet urgent storage needs without delay.

2. Precision Engineering The high-tech rollers are engineered to ensure precise dimensions and uniformity of the beams produced. This precision is crucial for ensuring compatibility with existing shelving and racking systems, minimizing the need for additional adjustments or modifications.

3. Automation Modern roll forming machines incorporate advanced automation technologies, including automatic feeding, cutting, and stacking systems. This reduces manual intervention, increases safety, and enhances overall productivity.

4. Customization Capability Many high-speed roll forming machines offer customization options. Businesses can produce beams in various sizes and shapes to suit their unique storage requirements, whether it's for pallet racking, shelving units, or other industrial applications.

5. Eco-Friendly Operations The production process of these machines is designed to minimize waste, maximally utilize raw materials, and typically requires less energy compared to older manufacturing techniques. This aligns with the growing emphasis on sustainability across industries.

Applications Across Industries

The versatility of high-speed galvanized storage beam roll forming machines makes them suitable for a wide range of applications. Industries such as manufacturing, logistics, warehousing, and retail benefit significantly from the use of storage beams produced by these machines.

In manufacturing environments, efficient storage systems help streamline operations by providing accessible and organized storage for raw materials and finished products. Similarly, logistics and warehousing operations rely on robust storage solutions for effective inventory management. Retailers can also utilize these beams for creating attractive display structures that enhance customer experience while ensuring durability.

Conclusion

Investing in a high-speed galvanized storage beam roll forming machine can profoundly impact the efficiency and effectiveness of storage systems in diverse industrial applications. With its high production rates, precision, and durability, this technology not only improves the operational efficiency of businesses but also enhances overall safety and organization within warehouses and storage facilities.

As industries continue to adapt to the changing demands of the market, embracing advanced manufacturing technologies such as high-speed roll forming will be essential. These machines not only represent a significant leap forward in storage solutions but also align with the goals of sustainability and efficiency that modern businesses strive to achieve. By selecting a high-speed galvanized storage beam roll forming machine, companies can position themselves at the forefront of innovation, better equipped to meet the challenges and opportunities of the future.