High-Speed Galvanized Storage Beam Roll Forming Machine Revolutionizing Storage Solutions

In the modern industrial landscape, efficiency and durability are paramount. The high-speed galvanized storage beam roll forming machine has emerged as a pivotal player in optimizing the production of storage beams, which are essential components for modern warehouses and storage facilities. By leveraging advanced technology, this machine not only enhances production speed but also ensures the structural integrity and longevity of the storage beams.

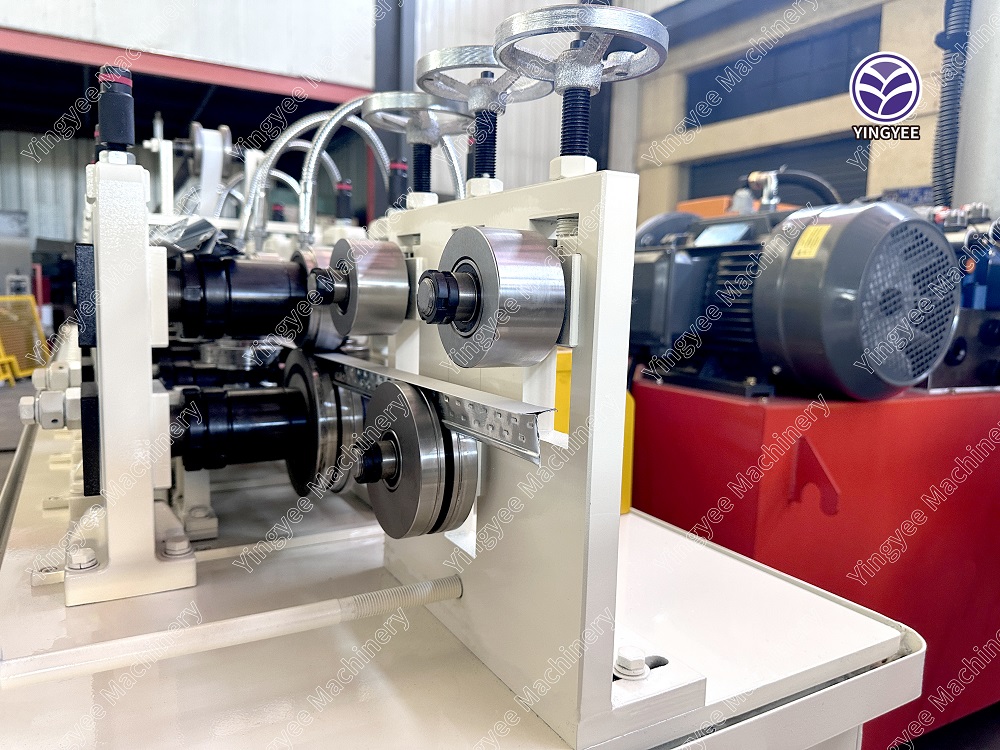

The core function of the high-speed roll forming machine is to convert flat steel coils into precisely shaped beams. This is achieved through a series of rollers, which gradually shape the material into the desired profiles. Featuring high-speed operations, these machines can produce a significant number of beams in a short period, meeting the demands of large-scale construction and storage projects. The ability to manufacture at high speeds while maintaining quality makes this machine an invaluable asset for manufacturers looking to reduce lead times and operational costs.

One of the standout features of these roll forming machines is their capability to produce galvanized beams. Galvanization involves applying a protective zinc coating to the steel, which acts as a barrier against rust and corrosion. This is particularly important in environments where humidity and other factors can lead to metal degradation. Storage beams manufactured with this process not only provide structural support but also ensure longevity, making them suitable for both indoor and outdoor use.

Additionally, the versatility of high-speed galvanized storage beam roll forming machines allows for customization. Manufacturers can adjust the design parameters to create beams that meet specific load-bearing requirements or conform to unique architectural designs. This flexibility is crucial in a market where customization is increasingly demanded by clients seeking tailored solutions for their storage needs.

Moreover, advancements in automation and technology have enhanced the operational efficiency of these machines. Features such as automatic cutting, and integrated quality control systems ensure consistent output and minimize waste. The capability to monitor production metrics in real-time allows operators to swiftly address any issues that may arise, further boosting productivity.

In conclusion, the high-speed galvanized storage beam roll forming machine represents a significant advancement in the manufacturing of storage solutions. It combines speed, efficiency, and durability, addressing the contemporary needs of the storage and logistics industry. As businesses continue to expand and require more sophisticated storage options, the role of this machine will only grow, making it an essential tool for manufacturers aiming to stay competitive in a dynamic marketplace. This technology not only supports the structural needs of warehouses but also contributes to sustainable practices through its efficient use of materials and energy.