High Precision Straightening Machines The Future of Leveling Technology

In the manufacturing and metalworking industries, the demand for high precision straightening machines has become increasingly important. These machines, often referred to as leveling machines, play a crucial role in ensuring that materials and components meet the stringent quality standards required for various applications. As technology advances, the importance of precision in the manufacturing process cannot be overstated.

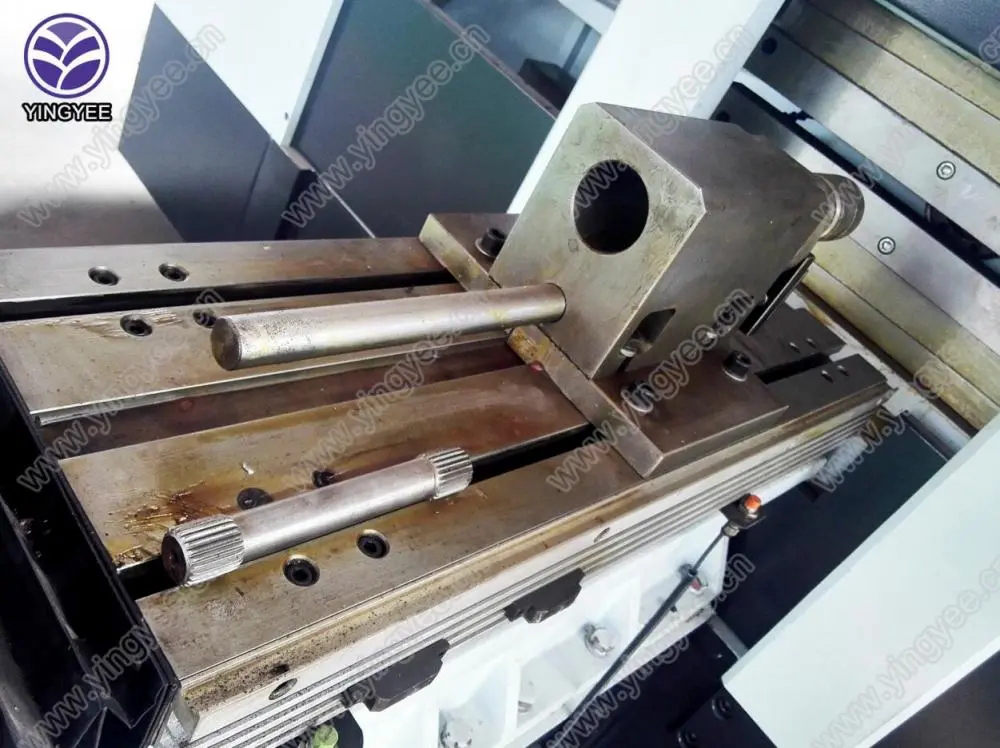

High precision straightening machines are designed to correct distortions in metal sheets, bars, and other materials resulting from processes like rolling, welding, or machining. The objective is to achieve a flat and smooth surface that not only meets aesthetic requirements but also enhances performance in subsequent manufacturing stages. These machines utilize a combination of mechanical and hydraulic systems to apply controlled forces that straighten and level the material with incredible accuracy.

One of the defining features of high precision straightening machines is their ability to handle a variety of materials, including steel, aluminum, and other alloys. This versatility makes them indispensable in industries such as automotive, aerospace, and construction, where precision and reliability are paramount. With the increasing complexity of engineering designs, the demand for materials that are not only strong but also uniformly flat and defect-free is higher than ever. Therefore, investing in advanced straightening technologies is critical for manufacturers aiming to maintain a competitive edge.

Modern straightening machines are equipped with sophisticated controls and sensors that allow for real-time monitoring of the leveling process. This ensures that the desired specifications are achieved consistently, reducing the likelihood of defects and material waste. Automation plays a significant role in these machines, enhancing their efficiency and productivity. Operators can set parameters and monitor the straightening process from a distance, which improves safety and reduces human error.

The benefits of high precision straightening machines extend beyond improved product quality. They also contribute to cost savings by minimizing the need for rework and reducing material waste. Moreover, by delivering components and materials that meet stringent tolerance standards, manufacturers can improve their overall production efficiency and throughput.

As industries evolve, the importance of high precision straightening machines will only grow. Manufacturers are not just looking for machines that can get the job done; they need solutions that can adapt to changing requirements and provide consistent results. Innovations in technology, including the integration of artificial intelligence and machine learning, are paving the way for even more advanced straightening machines that can predict issues before they occur, thus further enhancing efficiency.

In conclusion, high precision straightening machines are pivotal in the leveling process across various industries. Their ability to deliver precise and consistent results enables manufacturers to improve product quality, increase efficiency, and reduce costs. As manufacturers continue to prioritize precision, investing in these advanced machines will be essential for staying at the forefront of the competitive landscape. The future of manufacturing is undoubtedly intertwined with the evolution of high precision straightening technology.