In the ever-evolving landscape of industrial machinery, the high precision straightening machine leveling machine stands out as a vital tool for ensuring the utmost in product quality and manufacturing efficiency. These machines play a crucial role in a wide range of industries, ranging from automotive to aerospace, where the precision of metal parts is paramount.

The experience of utilizing high precision straightening machines can significantly enhance the quality of production lines. These machines boast the ability to correct even the most minuscule deviations in metal components, ensuring that all parts meet the stringent tolerance levels required by modern industry standards. The precision with which they operate often leads to a reduction in material waste, optimizing overall production costs and minimizing the need for costly rework of defective parts. Companies have reported substantial improvements in their production efficiency and product quality metrics by integrating these machines into their workflows.

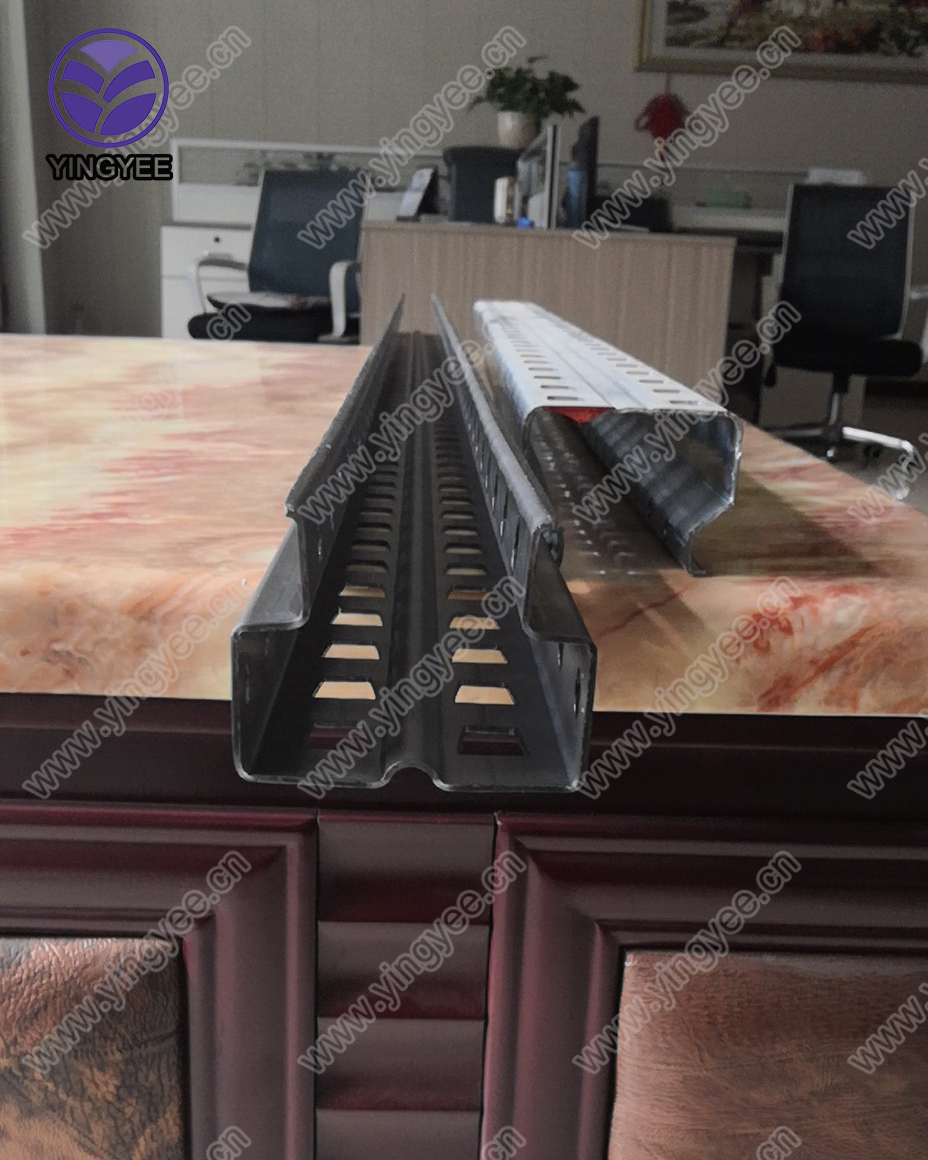

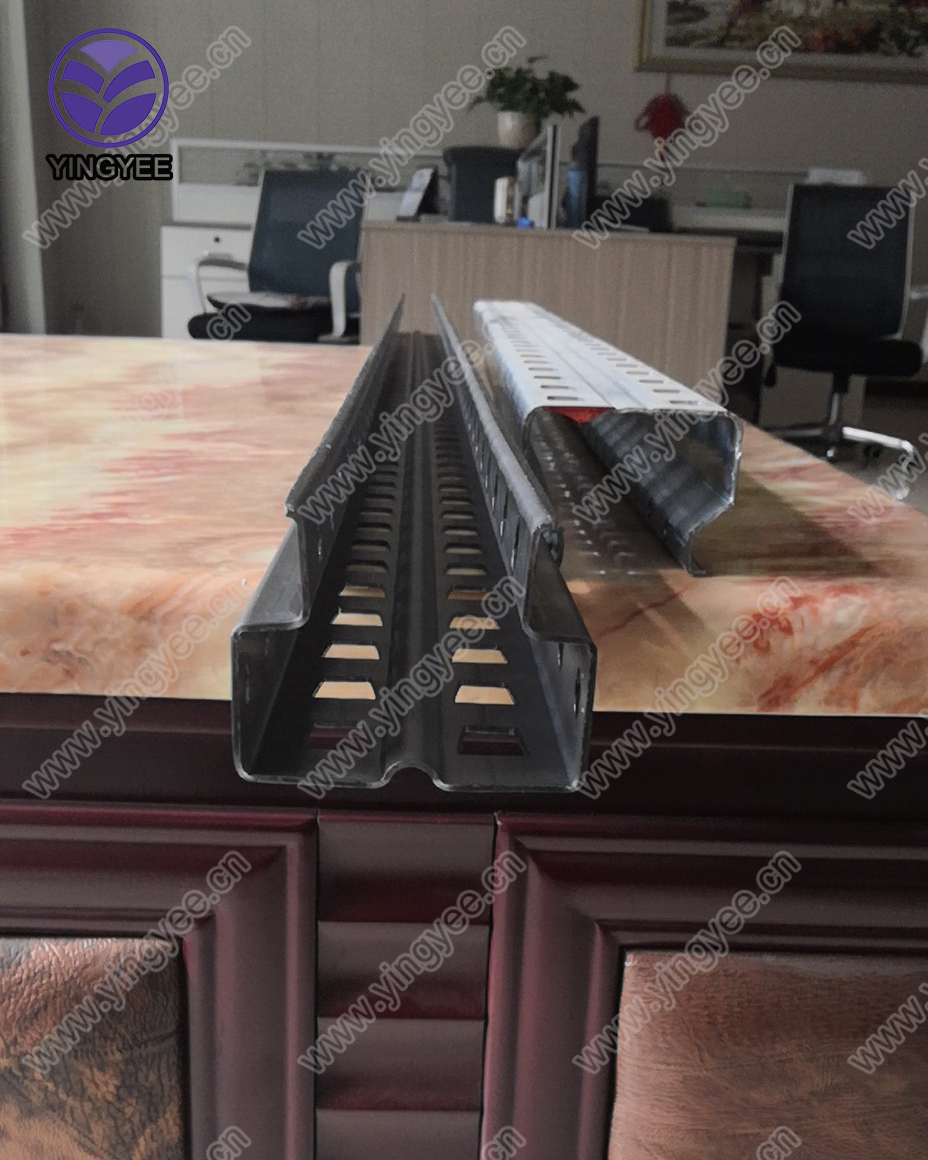

From an expertise standpoint, developing and maintaining high precision straightening machine leveling technology requires an extensive understanding of both mechanical engineering principles and material science. The machines are engineered to exert exactly controlled force over specific areas of a metal component to reshape it without causing undue stress or damage. They utilize advanced sensor technology to monitor and adjust pressure levels in real-time, a feature that distinguishes them from less precise leveling equipment. This precision ultimately assists manufacturers in meeting the rising demands for accuracy in component production.

Authority in the field of metal leveling technology is demonstrated by manufacturers who invest particularly in research and development to hone this machinery. Their continuous improvements in machine design underscore an authoritative grasp over machining precision, contributing significantly to reducing the time and labor costs associated with traditional straightening processes. Leading manufacturers collaborate with top-tier industry experts and clients to ensure that their machines not only meet but exceed current industrial standards, setting benchmarks for the entire industry.

high precision straightening machine leveling machine

Trustworthiness is another cornerstone of the high precision straightening machine leveling market, as users rely heavily on these tools to ensure the structural integrity of their products. Trust is earned through reliable performance, ease of use, and the provision of robust support and maintenance services. Mainstay companies offer comprehensive training and support to operators, ensuring that the machines are used to their fullest potential and that production delays due to technical issues are minimized. Such commitment to performance reliability and operator safety fosters a sense of trust that solidifies long-term client relationships.

For businesses contemplating the inclusion of high precision straightening machines in their manufacturing arsenal, careful consideration of machine capabilities, customization options, and post-purchase support is critical. Future technological advancements may introduce capabilities such as IoT integration and more sophisticated AI-driven adjustments, further enhancing the precision and efficiency of these machines. Staying informed about technological trends and industry innovations will be key for businesses aiming to maintain their competitive edge.

In conclusion, the high precision straightening machine leveling machine is indispensable in modern manufacturing, proving its value through enhanced production quality, reduced waste, and cost-effective operations. Its development and use embody pinnacle examples of industrial expertise, authority, and trustworthiness, ensuring paramount compliance with quality standards and fostering a stronger foundation for future advancements in manufacturing technology. As industries continue to demand ever-greater precision, these machines will only grow in prominence, aiding manufacturers in meeting the exacting expectations of the global market.