In the realm of construction and building materials, innovation drives efficiency and quality, particularly when it comes to tile production. The IBR tile making machine has emerged as a pivotal player in this niche, backed by its solid reputation for precision and productivity. Here, we delve into the nuances of this machinery, anchored in real-world experience and technical expertise, to uncover its transformative role in tile manufacturing.

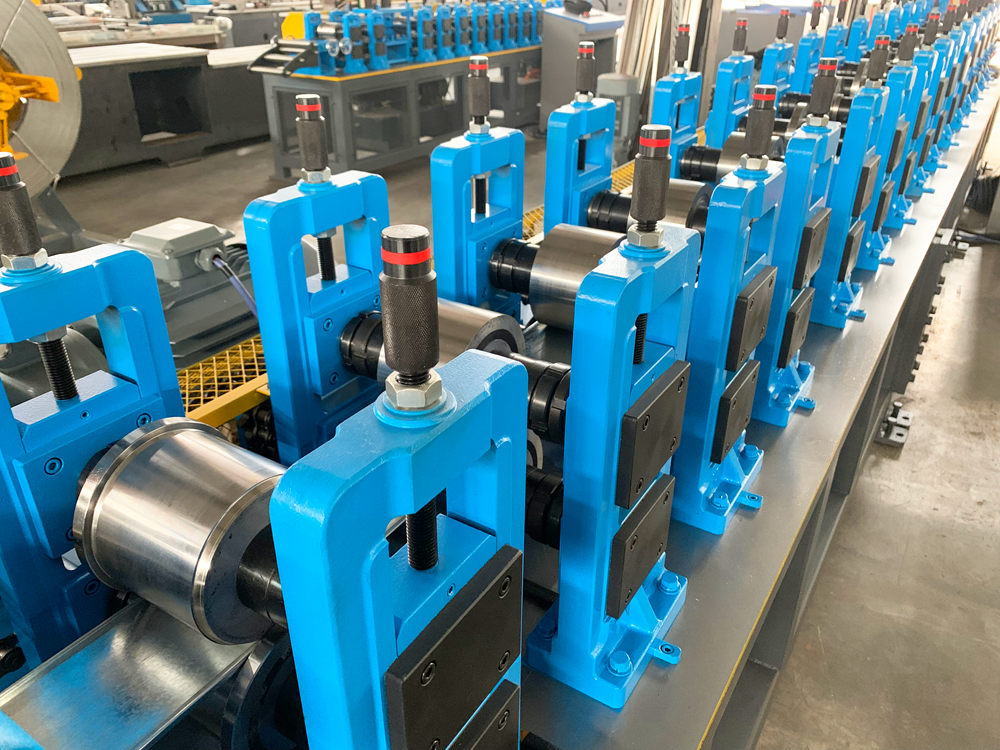

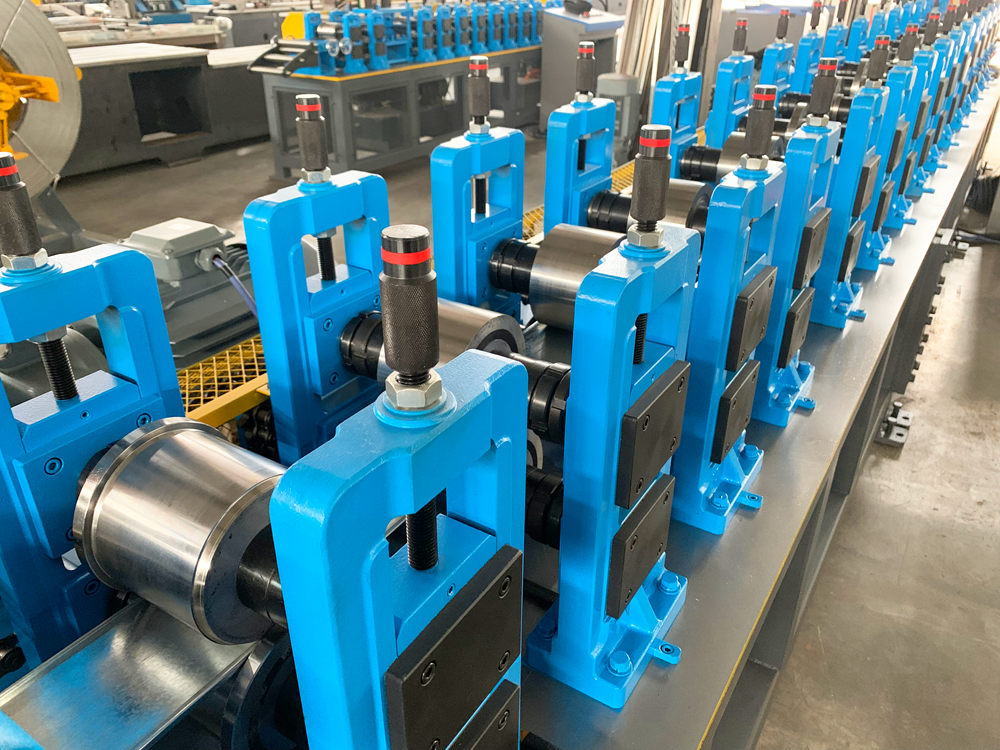

The unique efficiency of the IBR tile making machine is grounded in specialized engineering. Its design, which often integrates advanced automation technologies, allows for seamless operation and minimal manual intervention. By optimizing the production process, this machine significantly reduces the time from raw material input to finished product output, enabling manufacturers to meet tight deadlines without compromising on quality. Those familiar with traditional tile making processes will appreciate how this automation not only speeds up production but also reduces error, leading to uniformity and consistency across batches.

Experts in the tile manufacturing sector highlight the IBR tile machine's adaptability to various materials and design specifications. This flexibility is crucial in an industry that frequently demands custom solutions and diverse product offerings. The machine’s capability to adjust to different raw materials such as concrete, clay, or metal composites ensures that manufacturers can expand their product lines to meet consumer demand, without the need for additional machinery investments. This adaptability is not just a convenience but a testament to the machine’s engineering excellence.

Authoritativeness in the IBR tile making arena is exemplified by its adoption in leading construction firms globally. Trusted by industry giants, these machines have proven their reliability through rigorous field testing and continuous operation in demanding environments. Such widespread use serves as an endorsement of their capability and an assurance to potential buyers regarding their performance longevity. Additionally, the backing from reputable manufacturers known for their innovation in machinery adds another layer of credibility.

ibr tile making machine

In terms of trustworthiness, the IBR tile making machine stands out with its robust build quality and dependable service support. Third-party reviews and user testimonials frequently highlight the machine's durability, which translates to less downtime and lower maintenance costs—an important consideration for any business seeking to maintain consistent production levels. Furthermore, comprehensive customer support, often included with the purchase, ensures that any operational hiccups are swiftly addressed, preserving the investment’s ongoing value.

For businesses keen on sustainable practices, the IBR tile machine offers several environmentally-friendly features. Its efficient use of energy resources and minimized waste production contribute to a more sustainable manufacturing process. Such attributes not only appeal to environmentally conscious companies but also align with global efforts to reduce carbon footprints across industries. By adopting such eco-friendly machinery, manufacturers can enhance their corporate image while also benefiting from cost efficiencies resulting from reduced energy consumption.

Ultimately, investing in an IBR tile making machine goes beyond a mere purchase; it is a strategic decision anchored in enhancing production capabilities while maintaining high standards of quality and sustainability. The real-world experiences of adopting this technology paint a picture of transformative operational improvements, solidifying the IBR tile machine’s status as an indispensable tool in modern tile manufacturing. Through its blend of experience-driven design, expert engineering, authoritative market standing, and reliable performance, it continues to set the benchmark for excellence in the tile production landscape.