In the world of manufacturing and metal processing, achieving the highest level of precision and flatness is crucial for quality and functionality. The high precision straightening machine leveling machine is a technologically advanced solution designed to meet these stringent demands. For industries such as aerospace, automotive, electronics, and construction, where component precision can significantly influence performance, this machine becomes an indispensable tool.

Understanding the intricate workings of a high precision straightening machine begins with its sophisticated design. Engineered for excellence, these machines employ advanced control systems that utilize state-of-the-art sensors and feedback loops. This ensures that every material passing through the machine is leveled to the tightest tolerances possible. For operators, this means that even the most demanding specifications can be achieved consistently, providing peace of mind and reliability to stakeholders.

The expertise involved in operating a high precision straightening machine cannot be understated. Technicians are required to have a deep understanding of metallurgical properties and behavior under stress. Training includes mastering the use of digital interfaces through which parameters are set and monitored. This expertise not only enhances operational efficiency but also ensures the safety and longevity of equipment. Thus, only skilled personnel should be tasked with operation and maintenance to maintain the authoritativeness of the machine’s capabilities.

Authoritativeness in the production process is further asserted by the machine's versatility. It can cater to a wide range of materials, from steel and aluminum to specialized alloys and composites. This flexibility allows manufacturers to streamline operations and reduce downtime associated with changing machinery for different materials. The high precision straightening machine, with its universal applicability, thereby becomes an authoritative fixture in any modern production line.

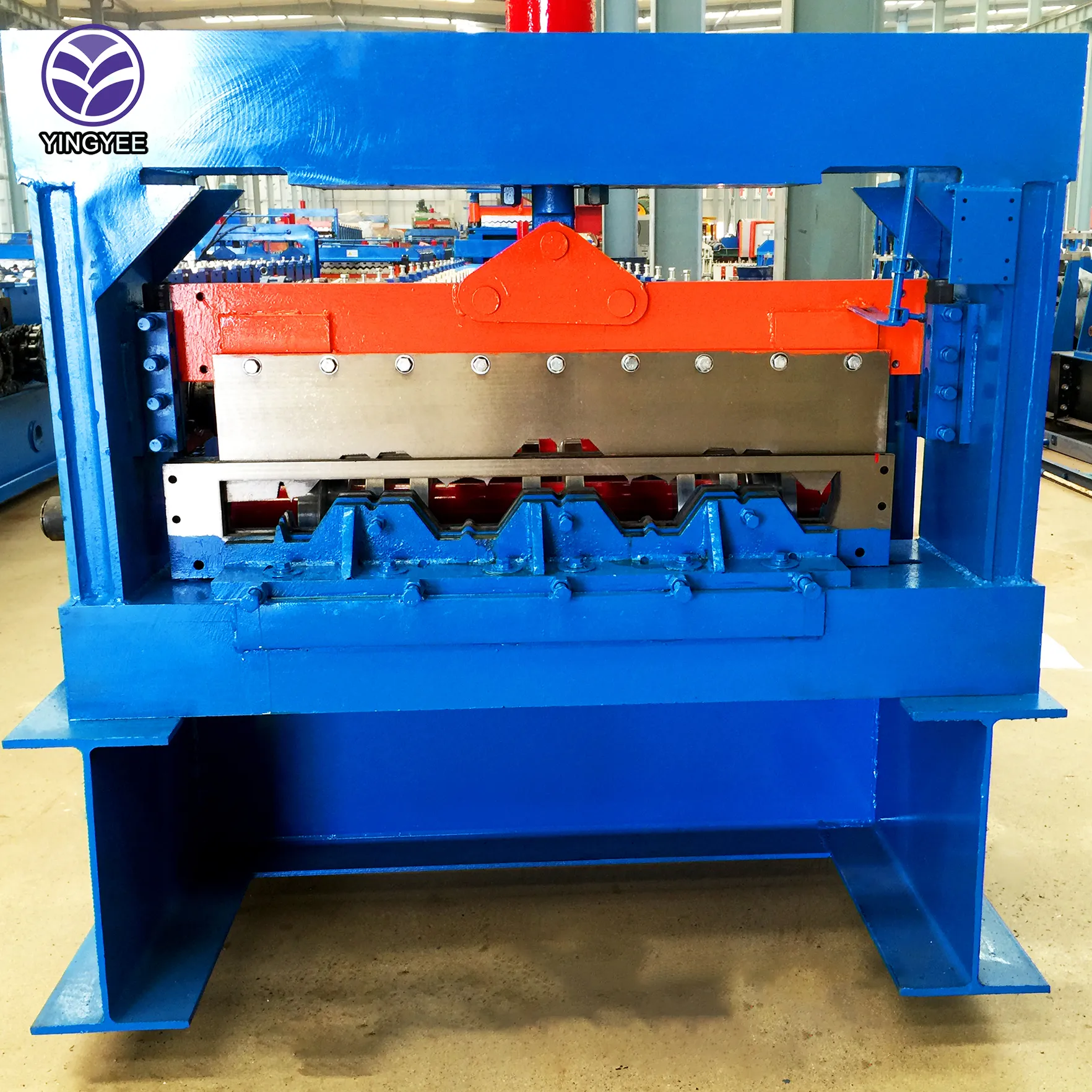

high precision straightening machine leveling machine

Trustworthiness of the results produced by this machine is corroborated through extensive testing and industry benchmarking. With certifications from recognized standard bodies and testimonials from leading manufacturing entities, stakeholders can trust the machine to deliver consistent, top-tier results. This trust is paramount in an industry where even the slightest deviation can lead to critical failures.

From a technical perspective, the machine's precision is achieved through several innovative features. One notable aspect is the roller configuration, designed to exert uniform pressure across the material surface. Coupled with high-resolution sensors that detect the minutest deviations, the machine adjusts in real-time, ensuring that output is impeccably level. Such features exemplify the machine's commitment to excellence and underline its status as a cornerstone of precision engineering.

The incorporation of IoT technologies further elevates the machine's operational capabilities, offering predictive maintenance insights and remote monitoring to anticipate issues before they disrupt production. This integration of technology aligns the machine with Industry 4.0 standards, marking it as a future-ready asset in any manufacturing repertoire.

In conclusion, the high precision straightening machine leveling machine stands at the crossroads of traditional craftsmanship and modern innovation. Its design and functionality reflect a deep understanding of material science and engineering principles. For businesses aiming to scale their output without compromising on quality, investing in this machine represents a strategic decision that promises long-term benefits and sustained competitive advantage. The machine not only redefines precision but also embodies the future of metal processing, reinforcing its irreplaceable role in today’s manufacturing landscape.