High Precision Straightening Machines Revolutionizing Metalworking

In the ever-evolving world of manufacturing, precision and efficiency are pivotal to maintaining competitive advantage. Among the technological advancements that have gained significant traction is the high precision straightening machine, a crucial tool for ensuring the accuracy and quality of metal components. These machines play an essential role in leveling deformed materials, enabling manufacturers to achieve superior precision in their production processes.

High precision straightening machines are designed to correct the distortions and imperfections that can occur during the manufacturing process, particularly in metalworking. Various factors, such as rolling, welding, and heat treatment, can lead to warping or bending in materials. These discrepancies can affect the performance and functionality of the final product, making straightening an essential step in the fabricating process.

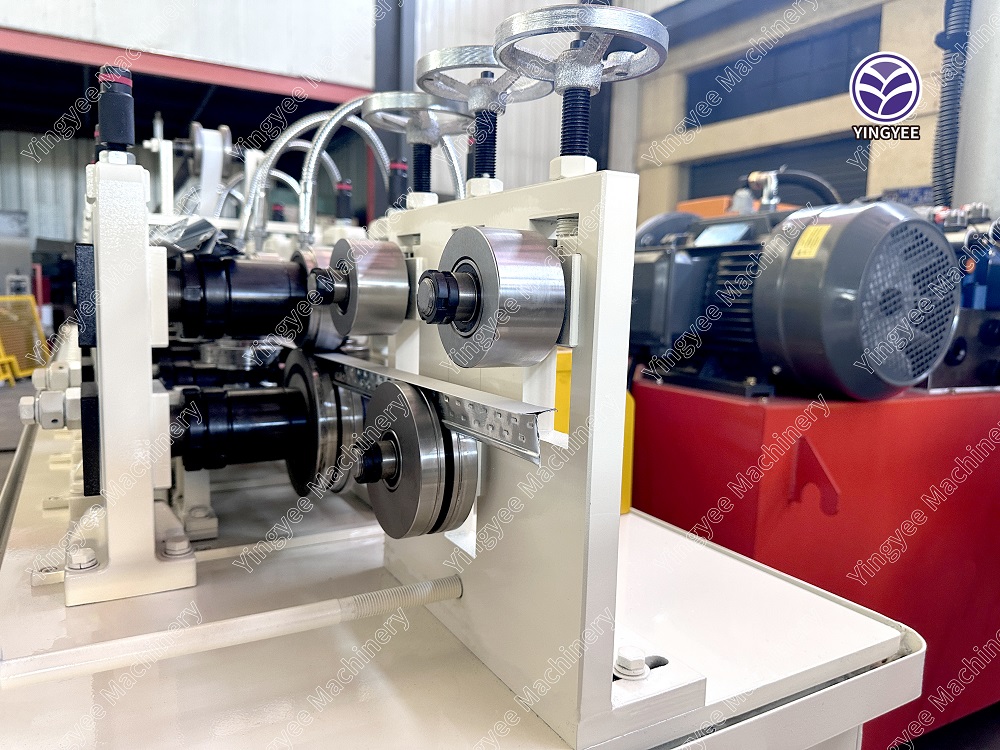

The technology employed in these machines has advanced significantly over the years. Modern straightening machines utilize sophisticated hydraulic principles and computer-controlled systems to apply consistent and even pressure across the material being leveled. This ensures that the straightening process is not only effective but also gentle enough to prevent further damage to the metal. The result is a high degree of flatness and straightness, which is crucial for subsequent machining operations.

One of the notable advantages of high precision straightening machines is their ability to work with a variety of materials, including steel, aluminum, and other alloys. This versatility makes them indispensable in industries ranging from automotive and aerospace to construction and fabrication. Manufacturers can obtain accurate and straight components, which leads to reduced waste, minimized rework, and ultimately, cost savings.

Moreover, the integration of automation and real-time monitoring systems has further enhanced the capability of these machines. Operators can now track the straightening process closely, ensuring that each component meets the specified tolerances. The data collected during the operation can also be analyzed to optimize performance and predict maintenance needs, thereby improving efficiency and uptime.

Furthermore, high precision straightening machines contribute significantly to sustainability in manufacturing. By ensuring that materials are straightened correctly, manufacturers can avoid the need to discard deformed parts, thus reducing material waste. This not only leads to cost-effectiveness but also supports environmentally friendly production practices.

In conclusion, high precision straightening machines represent a transformative force in the metalworking industry. Their ability to deliver superior precision, coupled with advancements in technology and automation, has made them vital in maintaining the quality and integrity of manufactured products. As industries continue to demand higher standards and lower costs, the role of these machines will be increasingly indispensable. Their impact on reducing waste and enhancing operational efficiency aligns with modern manufacturers’ goals of sustainability and continuous improvement. Embracing high precision straightening technology is essential for any forward-thinking business aiming to excel in today’s competitive market.