High Precision Straightening Machine The Future of Leveling Technology

In today’s fast-paced industrial environment, the demand for precision and efficiency in manufacturing processes has never been higher. At the heart of this demand lies the high precision straightening machine, a groundbreaking innovation that is revolutionizing the way materials are leveled and processed. This sophisticated equipment plays a pivotal role in ensuring the quality and performance of various industrial products, making it an indispensable asset across many sectors.

A high precision straightening machine specializes in aligning and leveling metallic components that may have become warped or distorted during production. These machines utilize advanced technology and engineering to achieve remarkable levels of accuracy, often within microns. This high degree of precision is vital, as even the slightest imperfection in a product can lead to significant issues in functionality and longevity.

One of the primary advantages of high precision straightening machines is their ability to enhance product quality. By ensuring that materials are perfectly leveled, these machines minimize the risk of defects that can compromise the integrity of the final product. In industries such as automotive manufacturing, aerospace, and construction, where tolerances are exceedingly tight, the ability to produce flawlessly straight components is crucial. Manufacturers that employ high precision straightening technology can experience lower rejection rates, reduced rework, and overall improved efficiency.

The operation of a high precision straightening machine is built on a combination of mechanical design and computerized control systems. Modern models are equipped with sophisticated sensors that continuously monitor the straightening process, providing real-time feedback and adjustments to ensure optimal performance. This level of automation not only enhances precision but also allows for greater consistency in production, reducing the variability that often plagues manual processes.

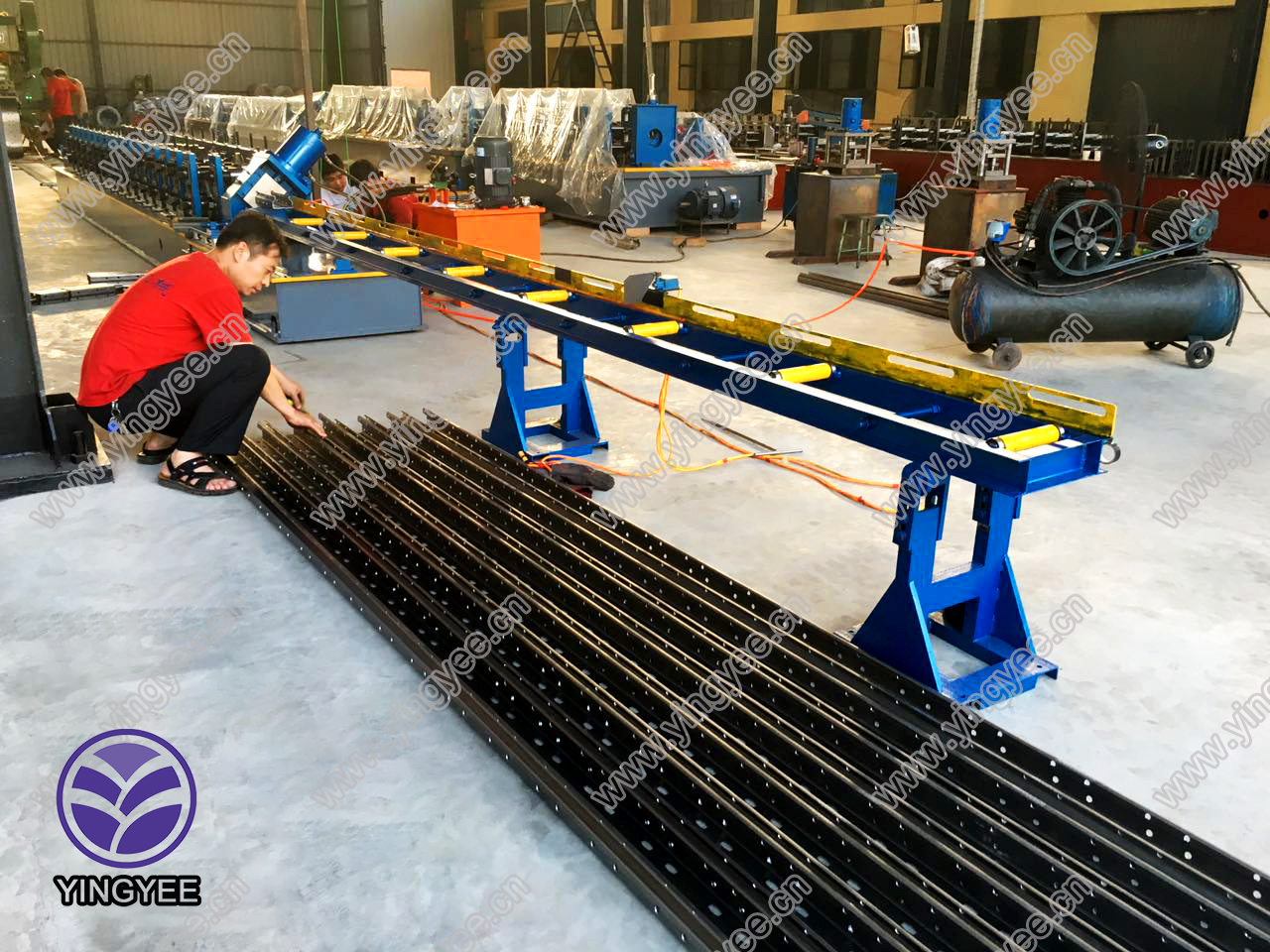

Moreover, high precision straightening machines can be custom-designed to handle a wide range of materials and component shapes, making them versatile tools in any manufacturing facility. Whether straightening rods, plates, or complex geometries, these machines can be adapted to suit various applications, further expanding their utility across different industries.

Efficiency is another critical advantage. High precision straightening machines are designed for rapid operation, allowing manufacturers to process large volumes of materials swiftly. This capability is particularly important in high-demand environments where time is of the essence. As a result, companies can meet production deadlines and respond more effectively to market changes, maintaining a competitive edge in their respective fields.

Energy efficiency is also a growing concern in manufacturing, and high precision straightening machines are increasingly being designed with this in mind. By incorporating energy-saving technologies and optimizing operational processes, manufacturers can significantly reduce their carbon footprint while also cutting operational costs.

In conclusion, the high precision straightening machine is transforming the landscape of industrial leveling and alignment. With its ability to deliver exceptional precision, enhance product quality, and improve operational efficiency, this innovative equipment is essential for modern manufacturing. As industries continue to evolve and demand for higher standards rises, investing in high precision straightening technology will undoubtedly remain a focal point for businesses looking to stay ahead of the curve. The future of manufacturing is bright, and high precision straightening machines are at the forefront of this technological revolution, ensuring that quality and efficiency are never compromised.