The Glazed Sheet Forming Machine Revolutionizing Roof Sheet Production

In the world of construction and roofing, the demand for high-quality materials continues to rise, fueled by the need for durability, aesthetics, and energy efficiency. Among the various solutions available, the glazed sheet forming machine stands out as a prominent innovation that has significantly transformed the production of roof sheets.

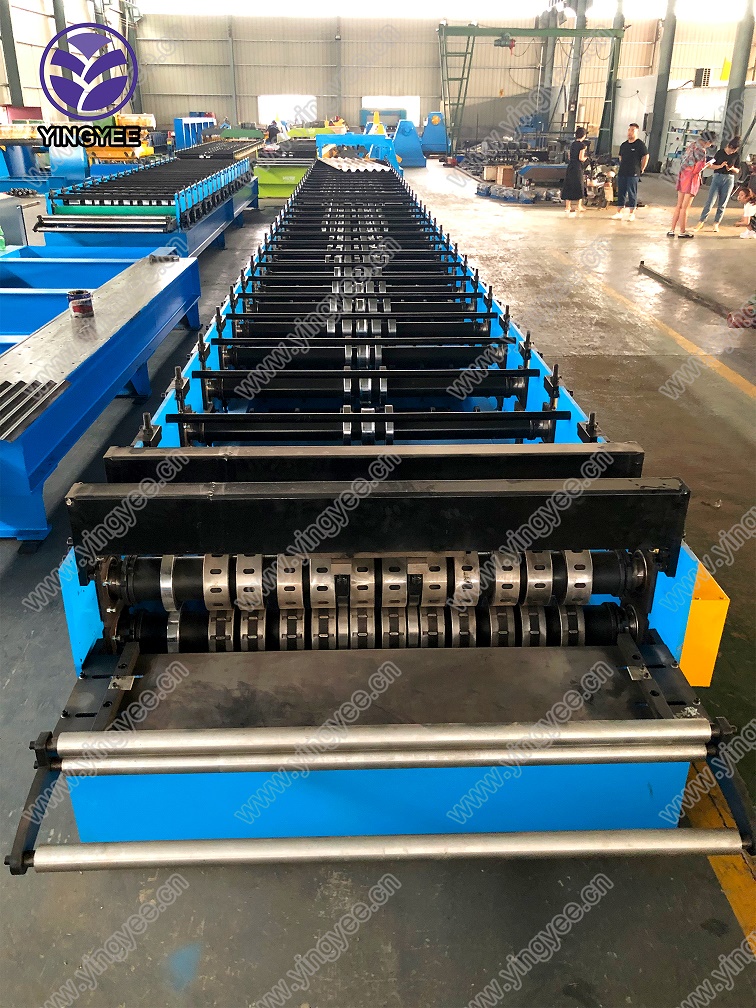

Understanding the Glazed Sheet Forming Machine

The glazed sheet forming machine is a specialized piece of machinery designed to produce roofing sheets with a glossy finish, often referred to as glazed sheets. These machines utilize advanced technology to shape, cut, and profile metal or polymer materials into sheets that are not only visually appealing but also highly functional. The glazed finish enhances the sheets' resistance to corrosion and weathering, making them suitable for various environments.

Advantages of Glazed Sheets

1. Aesthetic Appeal One of the primary advantages of glazed roofing sheets is their aesthetic value. The glossy surface reflects light and adds a modern touch to any structure. This feature is particularly appealing for residential homes, commercial buildings, and industrial facilities, where the roof's appearance plays a crucial role in overall design.

2. Durability Glazed sheets are made from high-quality materials that offer excellent durability. They are typically resistant to UV rays, making them less prone to fading and degradation over time. Furthermore, their smooth surface reduces the accumulation of dirt and debris, which can enhance their longevity.

3. Energy Efficiency Modern glazed sheets can be manufactured with energy-efficient properties. Reflective glazed sheets can help maintain cooler indoor temperatures by reflecting sunlight, which is especially beneficial in warmer climates. This feature can lead to lower energy costs and a reduced carbon footprint.

4. Ease of Installation The installation of glazed roofing sheets is generally straightforward, thanks to their lightweight nature and interlocking profiles. This ease of handling reduces labor costs and installation times, making them a favored choice among contractors.

Technological Innovations

The advancements in manufacturing technology have significantly improved the efficiency and capabilities of glazed sheet forming machines. With automated systems, these machines can produce sheets at a higher speed and with greater precision. Additionally, computer numerical control (CNC) technology allows for customizable designs, meeting the varied demands of builders and architects.

Modern glazed sheet forming machines often feature multi-functional capabilities, enabling them to produce different profiles in one continuous process. This versatility not only saves time but also minimizes waste, exemplifying a move towards sustainable manufacturing practices.

Applications of Glazed Sheets

Glazed roofing sheets have a wide range of applications. They are commonly used in residential roofing, industrial warehouses, commercial buildings, and agricultural structures. Their ability to provide an attractive yet functional roofing solution makes them a go-to option for many construction projects.

Moreover, the growing trend of eco-friendly building materials has further propelled the popularity of glazed sheets. With their energy-efficient properties and long lifespan, they contribute to sustainable building practices, which is becoming an essential consideration for many builders and homeowners.

Conclusion

The glazed sheet forming machine is more than just a tool; it represents a significant leap forward in roofing technology. As the construction industry continues to evolve, the demand for high-quality, aesthetically pleasing, and energy-efficient roofing materials will likely grow. The glazed sheet forming machine meets these needs, providing a reliable solution for manufacturers and builders alike. With ongoing technological advancements, the future of glazed roofing sheets appears bright, promising even greater innovations and applications in the years to come.