ERW Carbon Steel Tube Mill Advancements and Applications

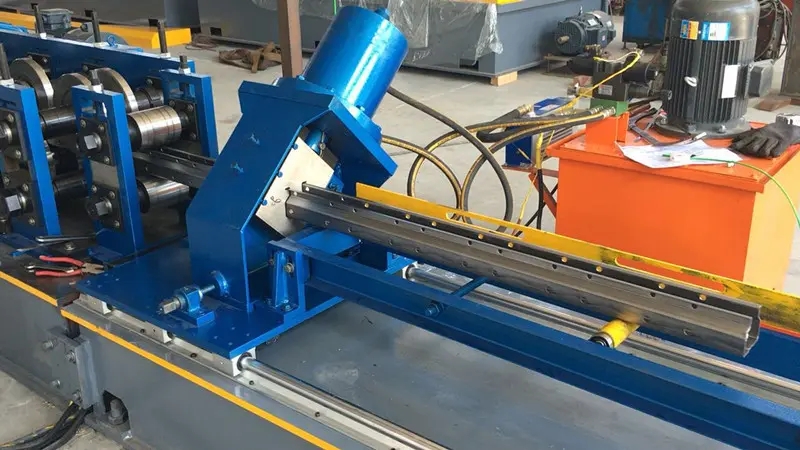

The Electric Resistance Welded (ERW) carbon steel tube mill is a significant innovation in modern manufacturing, particularly in the production of steel tubes. This technology uses a unique welding process that offers efficiency and cost-effectiveness, making it an essential component in various industries, including construction, automotive, and manufacturing.

ERW technology dates back to the mid-20th century, with advancements continually enhancing its capabilities. The process involves the use of high-frequency electric currents that heat the edges of the steel strip to the point where they can be fused together. This method not only ensures a robust weld but also minimizes steel wastage, making it an environmentally friendly option compared to other conventional methods.

ERW Carbon Steel Tube Mill Advancements and Applications

Moreover, ERW tubes exhibit excellent mechanical properties, making them ideal for applications requiring high strength and durability. The weld zones, which are typically the most vulnerable parts of welded structures, in ERW tubes are carefully monitored to meet stringent quality standards. Advanced non-destructive testing (NDT) techniques are employed to ensure the integrity of the welds, further enhancing the reliability of the final product.

In addition to their strength and versatility, ERW carbon steel tubes offer cost advantages. The high-speed production processes used in ERW tube mills reduce manufacturing costs. The efficient use of raw materials and the relatively low labor costs associated with automated systems contribute to this efficiency. As a result, businesses can benefit from reduced overheads and competitive pricing in the market.

The demand for ERW carbon steel tubes has surged in recent years, driven by the growth of various industries. In construction, these tubes are essential for building frameworks and support structures, providing the necessary strength without adding excessive weight. In the oil and gas sector, they are used for drilling and transportation, ensuring safety and reliability in challenging environments.

Furthermore, ERW carbon steel tubes have found their way into the automotive industry. Manufacturers utilize these tubes in the production of frames and chassis components, where strength-to-weight ratios are crucial. The lightweight yet strong nature of carbon steel tubes contributes to fuel efficiency in vehicles, aligning with global efforts to reduce carbon emissions.

In conclusion, the ERW carbon steel tube mill represents a vital element of modern manufacturing. Its innovative technology, combined with the ability to produce high-quality tubes at competitive prices, makes it indispensable across multiple sectors. With continued advancements in technology and increasing environmental awareness driving demand for lightweight and durable materials, the future of ERW carbon steel tube mills looks promising. As industries evolve and standards rise, these mills will remain at the forefront, providing solutions that meet the global demand for quality, efficiency, and sustainability in manufacturing.