Understanding the Z28-300% Thread Rolling Machine Parts

In the realm of manufacturing, efficient and precise machinery is the backbone of production processes, particularly when it comes to thread rolling operations. One such exemplary machine is the Z28-300% Thread Rolling Machine, known for its robust construction and high performance. Understanding its parts and their functions is crucial for optimally utilizing this equipment, ensuring longevity and reliability in operations.

Overview of the Z28-300% Thread Rolling Machine

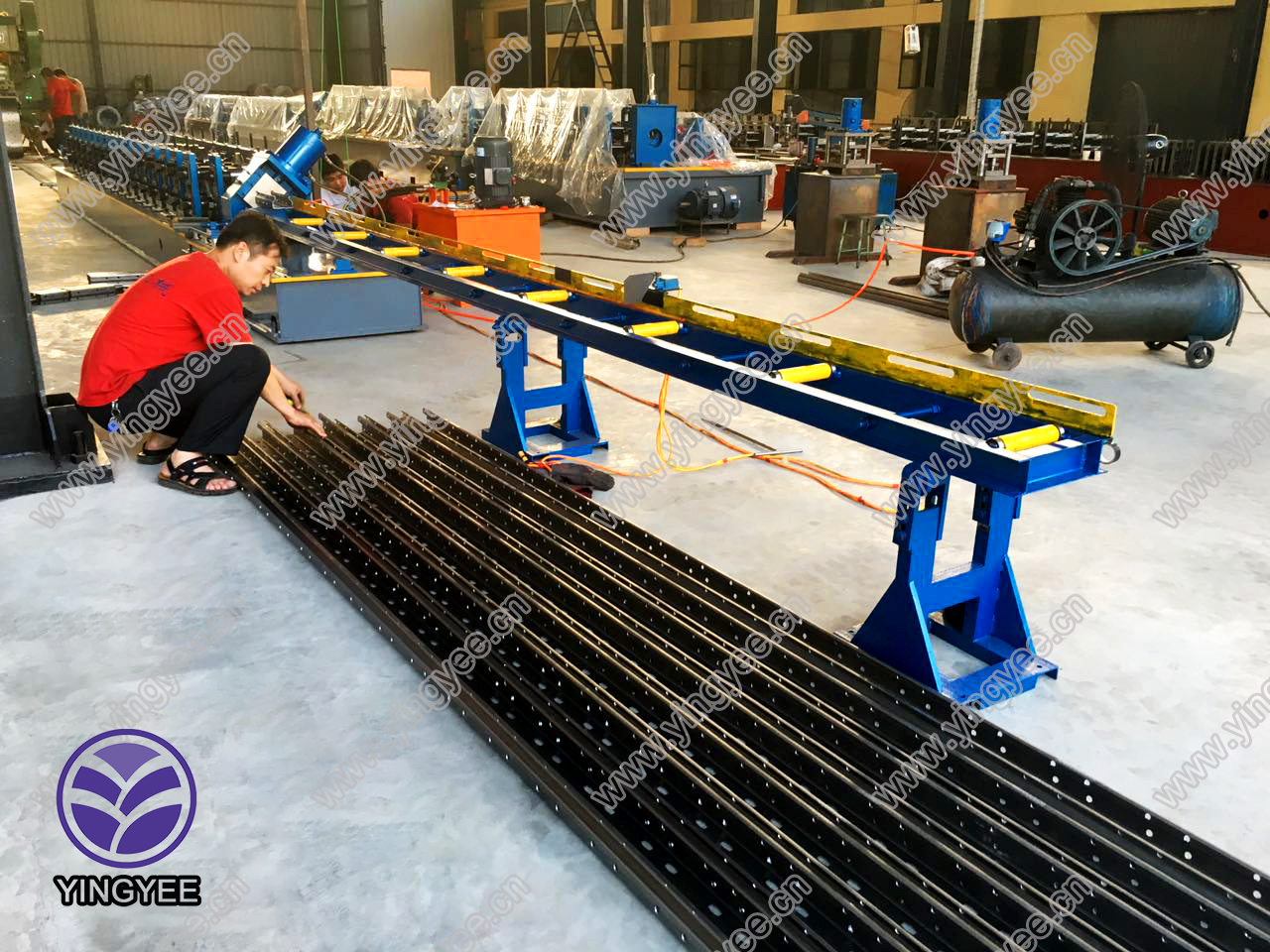

The Z28-300% Thread Rolling Machine is designed for producing various types of threads with exceptional precision and speed. It employs a rolling process that shapes metal into threads through a series of dies, eliminating the need for cutting and reducing waste. This method not only enhances the durability of the threads produced but also achieves higher production rates, making it a preferred choice in many manufacturing industries.

Key Components of the Z28-300% Thread Rolling Machine

1. Rolling Dies The rolling dies are among the most critical components of the Z28-300%. They come in different profiles and shapes tailored to produce specific thread types. High-quality alloys are typically used to manufacture these dies, ensuring they withstand the considerable forces involved during the rolling process.

2. Main Drive System The main drive system consists of a motor and a series of gears that provide the necessary torque and rotation speed. The efficiency of the drive system directly impacts the machine’s overall performance. Z28-300% features a high-efficiency motor that allows for adjustable speed settings, catering to various thread rolling requirements.

3. Feed Mechanism The feed mechanism is responsible for moving the workpiece into position for rolling. It includes elements like feed rollers and guides that ensure accurate placement and consistent motion, thereby enhancing the quality of the threaded product.

4. Control System Modern Z28-300% machines are equipped with advanced control systems that allow for precise adjustments and automation. These systems enable operators to program specific thread dimensions, speeds, and other parameters, ensuring a high level of consistency and repeatability in production.

5. Frame and Body The frame of the machine provides structural integrity and stability. It is designed to withstand the high pressures and stresses associated with the rolling process. The robust construction minimizes vibrations, ensuring that the thread rolling is smooth and efficient.

6. Lubrication System An effective lubrication system is essential for reducing friction between moving parts, minimizing wear and tear, and preventing overheating. The Z28-300% incorporates advanced lubrication technologies that automatically dispense oil or grease to critical areas, prolonging the lifespan of the machine components.

7. Safety Features Safety is paramount in any industrial setting. The Z28-300% includes various safety features such as emergency stop buttons, safety guards, and sensors that detect anomalies in machine operation. These features protect both the operator and the machine from potential hazards.

Conclusion

The Z28-300% Thread Rolling Machine is a sophisticated piece of equipment that plays a vital role in modern manufacturing. Its various parts work in harmony to produce high-quality threaded components efficiently. A thorough understanding of each component, from rolling dies to control systems, is essential for operators to maximize the machine's potential and maintain its performance over time. As technology continues to evolve, so too will the features and capabilities of machines like the Z28-300%, further enhancing the manufacturing landscape.