Understanding Z Purlin Machines A Key Component in Modern Construction

In the realm of modern construction, structural efficiency and durability play pivotal roles in the design and implementation of buildings and infrastructures. One of the remarkable innovations that have changed the landscape of construction is the Z purlin machine. This machine is specifically designed to manufacture Z purlins, which are essential for providing structural support in various applications.

What are Z Purlins?

Z purlins are horizontal structural components extensively used in metal building systems, especially in the construction of warehouses, storage buildings, and commercial complexes. They are named for their unique Z shape, which provides the necessary support and stability for roof and wall systems. Unlike traditional purlins, which can be less efficient in terms of load-bearing capabilities, Z purlins deliver improved strength-to-weight ratios, making them a preferred choice for architects and engineers.

The Role of the Z Purlin Machine

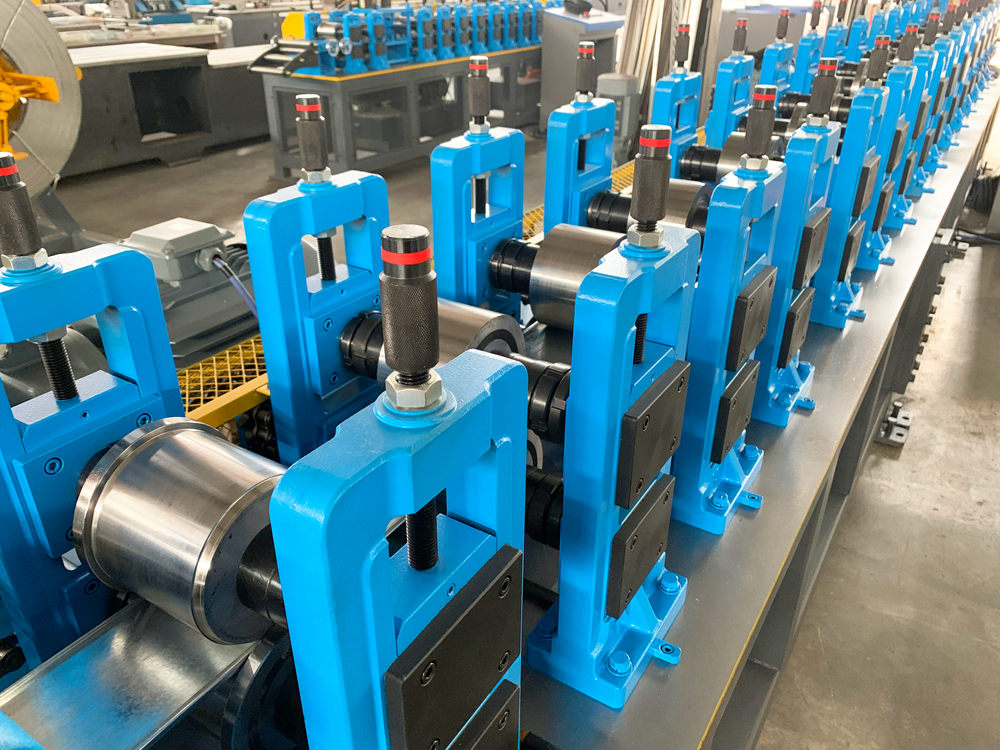

The Z purlin machine is an automated piece of equipment that fabricates Z purlins from flat steel sheets. These machines typically use advanced technology to achieve precision in dimensions and produce purlins at high speed. The process begins with feeding flat steel coils into the machine, where they undergo a series of operations, including roll forming, cutting, and punching.

1. Roll Forming This is the initial step where the machine shapes the steel into a Z configuration through a series of rollers. The roll forming process is continuous and allows for high production rates, making it ideal for large-scale construction projects.

2. Cutting and Punching Once the Z purlins are formed, they are cut to the desired length and may undergo punching to create holes for bolts and other fastening methods. This ensures that the purlins can be easily assembled on-site, enhancing the efficiency of the construction process.

Advantages of Z Purlin Machines

The use of Z purlin machines offers several advantages

- Efficiency Automated production drastically reduces the time required to manufacture Z purlins compared to manual methods. This speed enables construction teams to adhere to tight project timelines.

- Consistency Machines can produce purlins with high precision and consistency, leading to fewer defects and a higher quality end product.

- Cost-Effectiveness While the initial investment in a Z purlin machine may seem significant, the long-term savings in reduced labor costs and material waste can be substantial.

- Versatility Z purlin machines can be adjusted to manufacture purlins of various sizes and specifications, making them adaptable to different project requirements.

Applications in Construction

Z purlins are widely used in various structures, including

- Roofing Systems They provide essential support for roof panels, ensuring that the roof remains stable and secure under different weather conditions.

- Wall Framing In addition to roofs, Z purlins are also used as wall supports, contributing to the overall stability of buildings.

- Industrial Applications Many manufacturing and storage facilities utilize Z purlins due to their robust construction capabilities, allowing them to hold heavy loads.

Conclusion

The Z purlin machine stands as a testament to the advancements in construction technology, offering solutions that enhance efficiency, quality, and cost-effectiveness. As the construction industry continues to evolve, machines like these will play an increasingly vital role in delivering modern infrastructures that meet the demands of today and tomorrow. The ongoing development of such technologies promises a future where construction is not only faster but also more sustainable and resilient.