The Evolution and Importance of Steel Roof Roll Forming Machines

In the construction industry, efficiency and quality are paramount, particularly when it comes to roofing solutions. Over the years, the demand for durable and reliable roofing materials has driven innovations in manufacturing technologies. One notable advancement is the steel roof roll forming machine, a crucial piece of equipment that has transformed the production of metal roofing systems.

Steel roof roll forming machines are specifically designed to convert steel coils into various types of roofing profiles through a continuous process. These machines utilize a series of rolls that shape the metal into desired configurations while maintaining high precision. The benefits of using such machines are numerous, making them a staple in both commercial and residential construction projects.

Efficiency and Speed

One of the standout features of steel roof roll forming machines is their efficiency. Unlike traditional methods that often require extensive labor and time, these machines can produce roofing materials at a significantly faster rate. A roll forming machine can create long lengths of roofing sheets in a matter of minutes, which not only accelerates production times but also reduces labor costs. This efficiency is especially beneficial in large-scale projects where timely completion is critical.

Customizability

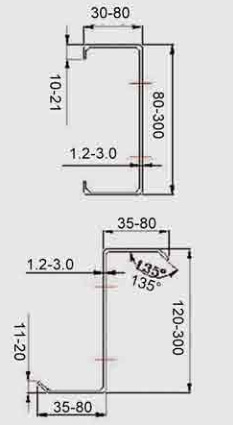

Another advantage of steel roof roll forming machines is their ability to produce customized profiles. Depending on the project requirements, operators can easily switch out roll sets to create different shapes and sizes of roofing panels. This versatility allows manufacturers to cater to a variety of architectural designs and preferences, ensuring that clients receive tailored solutions that meet their specific needs.

Quality Control

Quality is of utmost importance in construction, and steel roof roll forming machines excel in producing high-quality roofing materials. The continuous nature of the roll forming process ensures consistent thickness and dimensional accuracy across each sheet produced. Moreover, the use of galvanized or pre-painted steel increases the durability and lifespan of the roofing materials, offering excellent resistance against weather elements and corrosion. This reliability is crucial for protecting buildings and maintaining their structural integrity over time.

Cost-Effectiveness

Investing in a steel roof roll forming machine can lead to significant cost savings for manufacturers. The speed and efficiency of production enable companies to reduce operational costs while increasing output. Additionally, the durability of the finished products minimizes maintenance and replacement expenses for clients, making metal roofing solutions an attractive option in the long run. This cost-effectiveness is particularly appealing in competitive markets, where businesses are constantly seeking ways to enhance profit margins.

Environmental Considerations

In today's world, sustainability is a vital consideration across all industries, including construction. Steel roof roll forming machines contribute to environmentally friendly practices by facilitating the use of recyclable materials. Steel itself is one of the most recycled materials globally, and manufacturing it into long-lasting roofing solutions promotes a circular economy. Furthermore, the efficiency of the roll forming process minimizes waste compared to traditional production methods, aligning with sustainable development goals.

Conclusion

The steel roof roll forming machine represents a significant advancement in roofing technology, providing a blend of efficiency, customizability, quality, and cost-effectiveness. As the construction industry continues to evolve, these machines will play a pivotal role in meeting the growing demand for durable and reliable roofing solutions. With their ability to produce high-quality metal roofing quickly and sustainably, steel roof roll forming machines are set to remain an essential tool for manufacturers and builders alike.