The Roof Sheet Machine Revolutionizing Glazed Sheet Forming

In recent years, the roofing industry has witnessed significant advancements in technology, particularly with the introduction of specialized machines designed for glazed sheet forming. The roof sheet machine, specifically engineered for this purpose, has become a staple in both commercial and residential construction due to its efficiency, precision, and versatility.

Understanding the Roof Sheet Machine

A roof sheet machine is a type of equipment used to produce glazed sheets that are employed as roofing materials. These machines can form various types of profiles, catering to a wide range of architectural styles and structural requirements. The primary function of a roof sheet forming machine is to convert metal coils into finished glazed sheets, which are then used for roofing applications, effectively combining aesthetics with functionality.

The Process of Glazed Sheet Forming

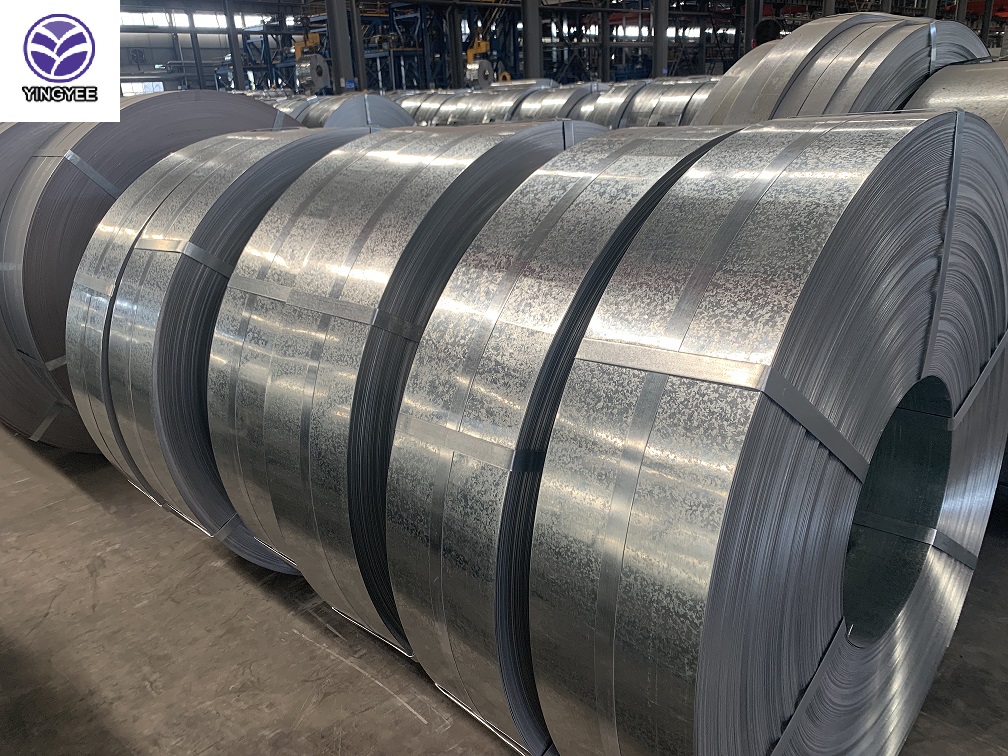

The production process begins with feeding a metal coil into the machine. This coil is typically made of galvanized steel or aluminum, known for their durability and weather resistance. Once fed into the machine, the coil undergoes a series of processes, including uncoiling, leveling, and feeding. The sheet is then shaped through a series of roller stations that progressively form the desired profile.

A key feature of the roof sheet machine is its ability to create glazings—thin, reflective surfaces that provide enhanced durability and aesthetic appeal. The forming process can also include additional features such as embossed patterns or varying thicknesses to meet specific design requirements. After shaping, the glazed sheets are cut to the desired length.

Benefits of Using Roof Sheet Machines

1. Efficiency Roof sheet machines operate at high speeds, significantly reducing production time compared to manual methods. This efficiency not only saves time but also lowers labor costs, making it a cost-effective solution for manufacturers.

2. Quality and Consistency Automated machinery ensures high accuracy in dimensions and uniformity in product quality. This consistency is crucial for projects that demand precision, such as large commercial developments or bespoke residential buildings.

3. Versatility Roof sheet machines can be adjusted to produce various profiles and thicknesses, making them suitable for a wide range of applications. This versatility allows manufacturers to cater to diverse client needs, from simple garden sheds to complex industrial buildings.

4. Sustainability Many modern roof sheet machines are designed with energy efficiency in mind, utilizing advanced technology that minimizes waste material. Additionally, the use of recycled materials in metal coils promotes sustainability within the industry.

Challenges and Considerations

Despite the numerous benefits, there are some challenges associated with roof sheet machines. Initial investment costs can be high, especially for advanced models with numerous features. Additionally, operators require training to effectively manage and maintain the machinery, ensuring that safety standards are met.

Moreover, as the demand for environmentally friendly construction materials grows, manufacturers must adapt by exploring eco-friendly options and practices. Employing machines that support the production of sustainable materials can provide a competitive edge in the market.

Conclusion

The roof sheet machine represents a remarkable advancement in the roofing industry, offering benefits that range from enhanced efficiency to superior product quality. As construction methods continue to evolve, these machines will undoubtedly play a crucial role in shaping the future of architectural design and building practices. Investing in such technology not only meets the current demands of the market but also prepares manufacturers for the challenges and innovations yet to come.