The heavy duty storage rack rolling machine is an innovative piece of equipment transforming how industries manage storage solutions. In warehouses and industrial sectors, where every square foot signifies potential revenue, optimizing storage space is crucial. This machine does more than offer storage solutions; it optimizes efficiency, enhances safety, and significantly impacts productivity.

Imagine a vast warehouse where each product must be readily accessible and securely stored. The heavy duty storage rack rolling machine plays a pivotal role in these settings, engineered to handle substantial loads with precision and ease. Built from robust materials, it ensures durability, withstanding the rigors of heavy use over time. Its design caters to industries requiring dependable and efficient storage solutions, making it an indispensable asset.

Users report a marked improvement in operational flow after integrating the rack rolling machine. Tony Harper, a warehouse manager with over a decade of experience, shared insights into his facility's transformation. Before implementing this system, we faced constant challenges with space and accessibility. Since incorporating the rolling racks, our storage capability has increased by nearly 40%. It's a game changer, not just in space utilization but also in our daily operations, he notes.

Expertise in the design of these machines emphasizes their adaptability. They are engineered to accommodate various storage needs, featuring adjustable shelving and customizable dimensions. This flexibility permits an array of industrial applications, from storing heavy machinery parts to organizing large inventories of palletized goods. The machine's rolling mechanism facilitates easy movement and reorganization, making it advantageous for dynamic environments that require frequent layout changes.

Authoritativeness is a critical aspect of manufacturing and implementing the heavy duty storage rack rolling machine. Leading experts in industrial engineering, like Dr. Susan Blake, have acknowledged the machine’s contribution to modern storage solutions. The innovation behind these machines is not merely structural. It incorporates mechanized features that enhance both user safety and equipment longevity, Dr. Blake emphasizes. Her research has highlighted significant reductions in workplace accidents due to these machines, further underscoring their value in enhancing operational safety standards.

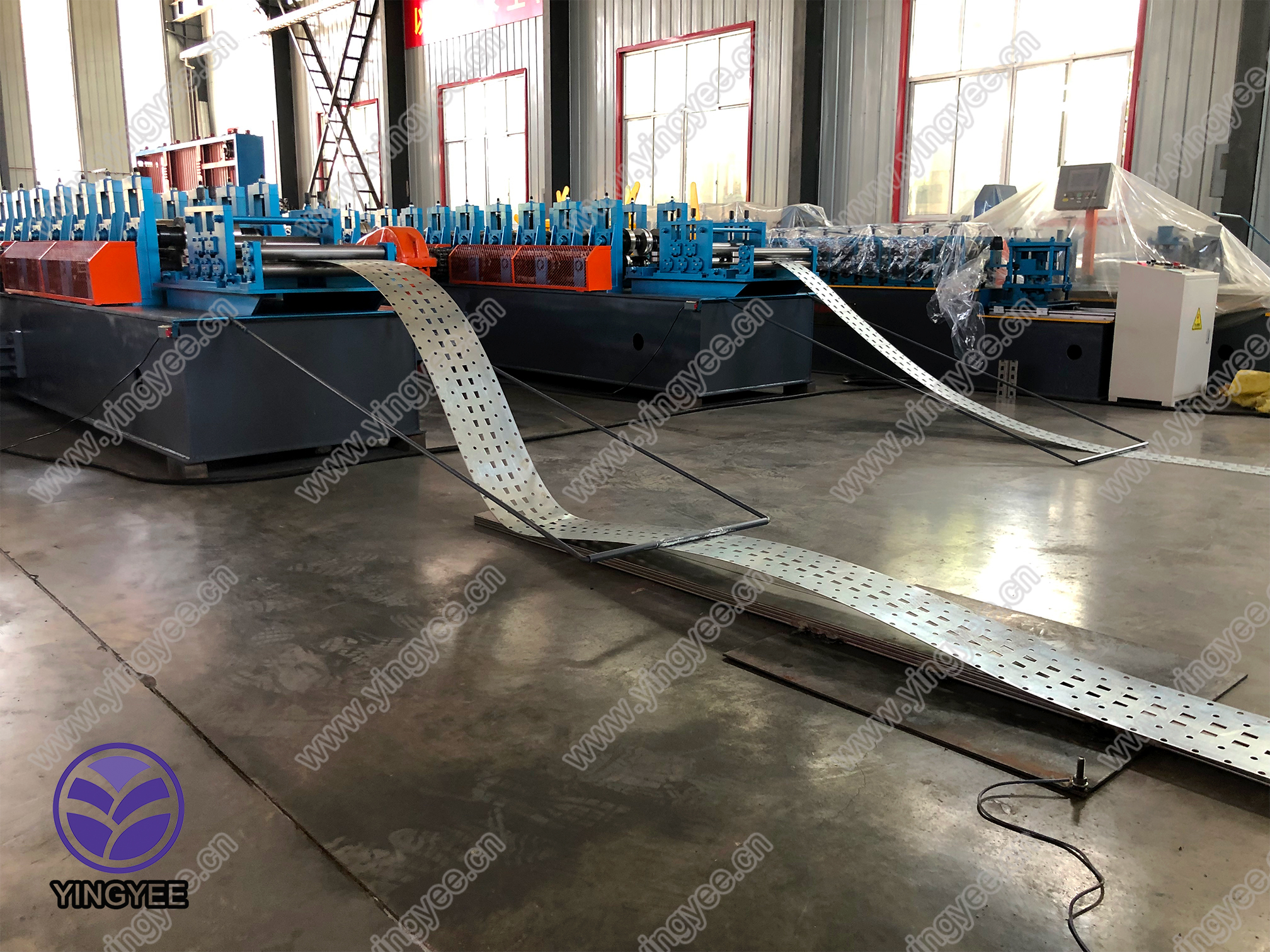

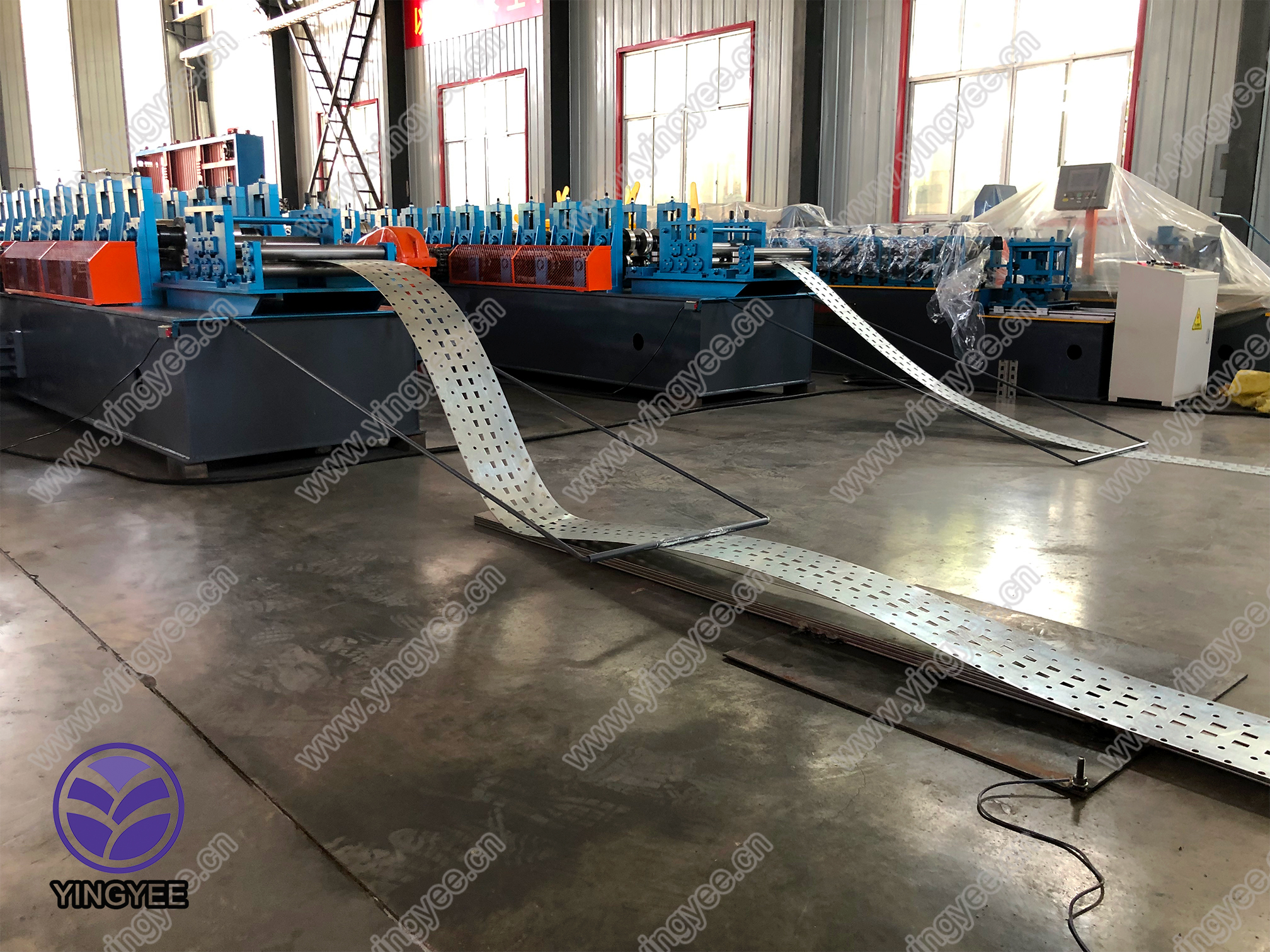

heavy duty storage rack rolling machine

Trustworthiness is assured through rigorous testing and certification processes that each machine undergoes before hitting the market. Reputable manufacturers adhere to stringent safety and quality standards, ensuring that their products not only perform effectively but also safely. Certifications from recognized industry bodies authenticate the machine's compliance with safety regulations, instilling confidence in potential buyers regarding both performance and safety.

For potential buyers, understanding the return on investment is crucial. Richard Lewis, an industrial procurement expert, advises organizations to consider the long-term benefits. The upfront cost of these machines might seem substantial, but when you factor in the increased storage capacity, improved efficiency, and reduced labor costs, the return on investment is quickly realized, Lewis explains. The enhancement in storage and operational capabilities translates directly into financial benefits, a perspective that decision-makers find compelling.

In summary, the heavy duty storage rack rolling machine is a testament to the advancement in industrial storage solutions. It exemplifies new standards in durability, adaptability, and safety. With endorsements from industry experts and testimonies from users, its value is clear. The machine has not only redefined storage capabilities but has also optimized efficiency, creating a safer and more productive work environment. For industries focused on innovation and efficiency, investing in this technology is a strategic move towards a more streamlined and cost-effective operation.

Incorporating such machines into industrial settings not only maximizes storage but also significantly impacts operational efficiency positively. This change is evidenced by increased productivity, higher safety standards, and substantial cost savings, making it a vital component for modern warehouses aiming for peak efficiency.