Heavy Duty Cable Tray Forming Machine Revolutionizing the Cable Management Industry

In today's rapidly evolving industrial landscape, efficient cable management is of paramount importance. As power and communication networks expand, the demand for reliable cable management solutions grows. One standout innovation in this realm is the heavy-duty cable tray forming machine. This advanced equipment revolutionizes the manufacturing process of cable trays, which are essential for organizing and protecting electrical and communication cables.

Understanding Heavy Duty Cable Trays

Cable trays are structural systems used to support insulated electrical cables and facilitate their organization and safety. Unlike traditional methods of managing cables, such as conduits or raceways, cable trays allow for easier access and better airflow. Heavy-duty cable trays are specifically designed to handle heavy and numerous cables, ensuring they remain secure and protected in various environments, including commercial buildings, industrial facilities, and outdoor setups.

The Functionality of Cable Tray Forming Machines

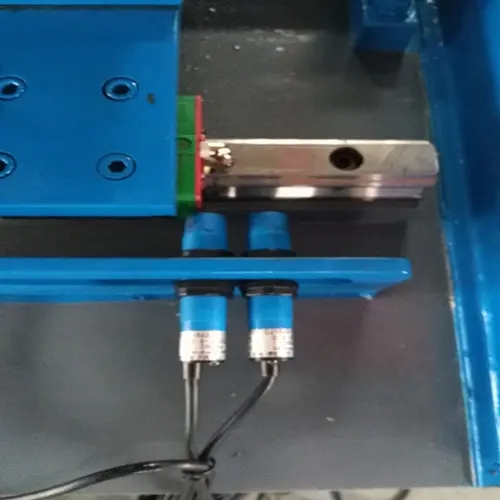

A heavy-duty cable tray forming machine automates the production of these essential fixtures, streamlining the manufacturing process. The machine is equipped with advanced technologies that enable it to cut, bend, and shape metal sheets, typically made of steel or aluminum, into various configurations of cable trays. The process ensures a high level of precision and consistency, essential for maintaining the structural integrity and aesthetic appeal of the finished product.

These machines can produce various types of cable trays, including perforated, ladder, and solid-bottom trays. The flexibility of modern cable tray forming machines allows manufacturers to meet specific client requirements, producing customized trays that align with unique project parameters.

Advantages of Heavy Duty Cable Tray Forming Machines

1. Increased Efficiency Automation significantly reduces production time. Traditional methods require manual labor, which can be slower and error-prone. By contrast, a forming machine can operate continuously, rapidly producing large quantities of trays without compromising quality.

2. Cost-Effectiveness While the initial investment in a heavy-duty cable tray forming machine can be substantial, the long-term savings are notable. Higher production rates, reduced labor costs, and minimized waste contribute to an overall decrease in manufacturing expenses.

3. Enhanced Quality Control Modern machines come equipped with computer numerical control (CNC) technology, ensuring high precision in cutting and shaping. This level of accuracy reduces the likelihood of defects and increases overall product quality, which is crucial in industries where safety and compliance are non-negotiable.

4. Versatility The ability to produce multiple tray styles from a single machine is a significant advantage. Manufacturers can adapt to market demands quickly, producing various products without the need for extensive retooling or changes to the production line.

5. Sustainability Many heavy-duty cable tray forming machines are designed to minimize waste and energy consumption, aligning with the increasing industry focus on sustainable practices. These machines can efficiently work with recycled materials, appealing to environmentally conscious businesses.

Conclusion

The heavy-duty cable tray forming machine represents a pivotal development in the cable management industry. By combining efficiency, precision, and versatility, these machines enable manufacturers to produce high-quality cable trays that meet the evolving demands of modern infrastructure. As industries continue to grow and develop, the role of such innovative machinery will undoubtedly become more critical, ensuring that companies can achieve reliability and organization in their electrical and communication networks. Investing in a heavy-duty cable tray forming machine is not merely a decision for the present; it is a strategic move towards a more efficient and sustainable future in cable management.