Heavy-Duty Cable Tray Roll Forming Machine The Backbone of Modern Electrical Infrastructure

In today's rapidly advancing technological landscape, the demand for reliable and durable electrical infrastructure is paramount. One of the key components that support this infrastructure is the heavy-duty cable tray system, designed to organize and protect electrical cables in commercial and industrial settings. At the heart of this system lies the heavy-duty cable tray roll forming machine, an essential piece of equipment that streamlines the manufacturing process.

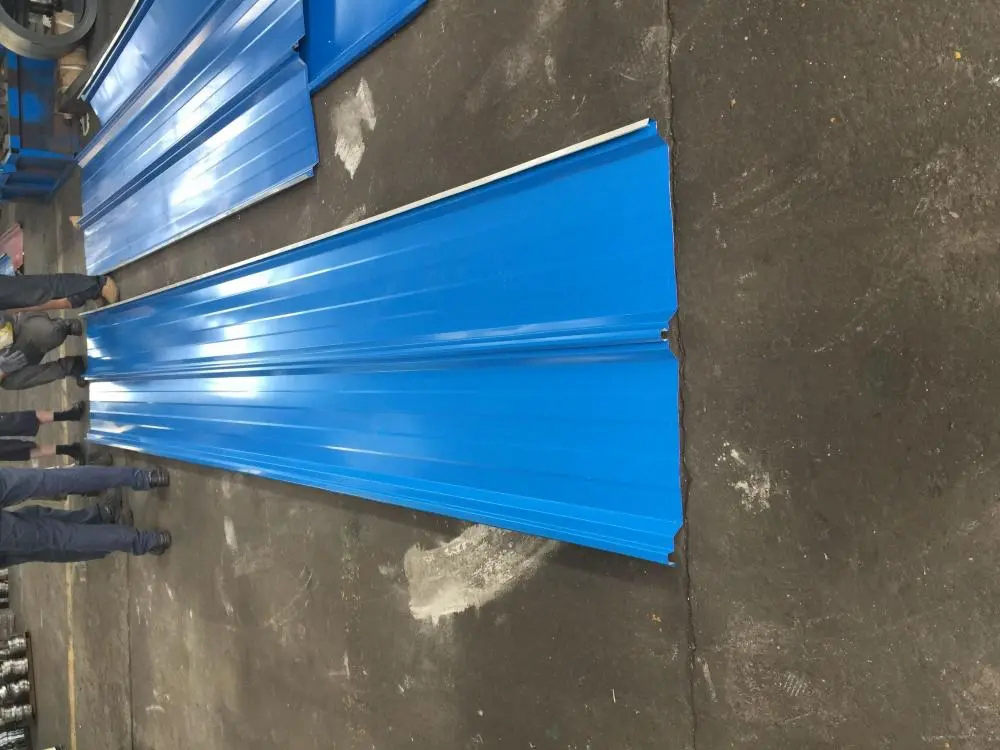

A heavy-duty cable tray roll forming machine is specifically engineered to produce cable trays that can withstand significant loads and harsh environmental conditions. These machines utilize advanced roll forming technology, allowing for the continuous bending of steel sheets into precise tray shapes. The process involves feeding flat strips of metal into the machine, which then forms them into the desired profile through a series of rollers.

One of the standout features of modern cable tray roll forming machines is their versatility. They can produce various tray sizes and designs, catering to the diverse needs of different industries, including telecommunications, construction, and data centers. Manufacturers can easily switch between different profiles by adjusting the machine settings, optimizing production efficiency and minimizing downtime.

The heavy-duty nature of these cable trays is vital for ensuring safety and reliability in electrical installations. They are designed to support heavy loads of cables, providing robust support in scenarios where multiple cables are bundled together. Additionally, many of these trays come with fire-resistant coatings and are designed to operate in extreme temperatures, further enhancing their durability.

Another significant advantage of using a roll forming machine is the reduction of material waste. The process is highly efficient, with minimal scrap generated during production. This not only contributes to cost savings but also aligns with sustainability efforts in manufacturing. Businesses are increasingly adopting eco-friendly practices, and roll forming technology helps in minimizing the environmental impact.

Furthermore, the automation capabilities of these machines allow for streamlined operations. With features such as programmable logic controllers (PLCs), manufacturers can achieve high levels of precision and consistency in their products. This automation also leads to higher production speeds, ensuring that businesses can meet market demands swiftly.

In conclusion, the heavy-duty cable tray roll forming machine plays a crucial role in supporting modern electrical infrastructure. By enabling the efficient production of robust cable management systems, these machines not only enhance safety and reliability but also promote sustainability in manufacturing processes. As industries continue to evolve, the significance of such machines will only grow, solidifying their place as indispensable tools in electrical installations.