Understanding Gutter Roll Formers A Key Innovation in Metal Fabrication

In the realm of metal fabrication, the gutter roll former stands out as a crucial piece of machinery. This equipment is specifically designed to create seamless and efficient gutters that are vital for effective rainwater management in both residential and commercial buildings. With the growing emphasis on stormwater management and sustainable architecture, the gutter roll former is becoming increasingly significant in construction and renovation projects.

What is a Gutter Roll Former?

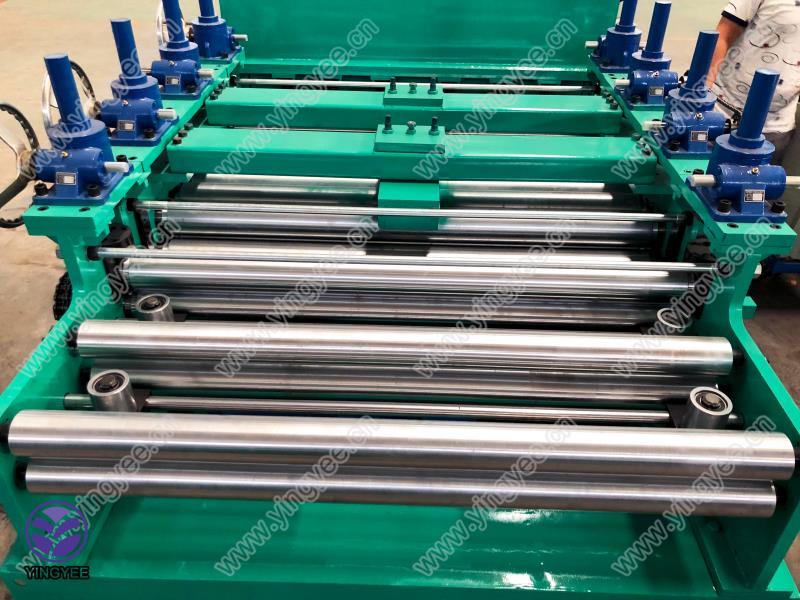

A gutter roll former is a specialized machine that takes flat strips of metal, typically galvanized steel, aluminum, or other durable materials, and converts them into the shape of a gutter through a series of rollers. The process involves feeding the metal strip through a series of forming rollers, each progressively shaping the material until it reaches the desired profile. The final product is a continuous length of gutter that can be cut to specified sizes for installation.

The Manufacturing Process

The manufacturing process of gutters using a roll former is efficient and cost-effective. Initially, the raw material is uncoiled and fed into the machine. As the metal passes through multiple rollers, it is gradually shaped into the desired gutter profile. During this process, careful adjustments can be made to ensure that the final product meets specific dimensions and strength requirements.

Once the gutter reaches the end of the rolling line, it can be cut into manageable lengths, ready for shipping or immediate installation. The ability to create long runs of seamless gutters minimizes the need for joints and reduces the risk of leaks, a common issue in traditional gutter systems.

Advantages of Gutter Roll Formers

2. Customization Many gutter roll formers offer adjustable settings, enabling producers to create gutters in various profiles and sizes to suit different architectural needs.

3. Material Versatility Gutter roll formers can work with a variety of materials, which allows for design flexibility according to aesthetic and functional requirements.

4. Reduced Waste Since the creation of gutters can be done in continuous lengths, material wastage is minimized compared to traditional cutting methods.

5. Durability The gutters produced by roll formers are typically stronger and more resilient than their counterparts, offering long-lasting performance in various weather conditions.

Applications in Construction

The gutters produced by gutter roll formers play a crucial role in managing rainwater and preventing water damage to buildings. Efficient gutter systems are essential for directing rainwater away from roofs and foundations, thus reducing the risk of flooding and structural deterioration. Furthermore, aesthetically pleasing gutters can significantly enhance the architectural appeal of a building, making them a popular choice in both residential and commercial projects.

Conclusion

The gutter roll former represents a pivotal innovation in the field of metal fabrication. With its capabilities to produce high-quality, customized gutters efficiently, it meets the increasing demands of modern construction. As the importance of effective water management systems continues to grow, the gutter roll former is likely to remain an integral component of the construction industry. Embracing this technology not only enhances the functionality of building designs but also contributes to the sustainability of infrastructure, ensuring a safer and more efficient future for urban development.