Gutter Elbow Machine for Sale A Comprehensive Guide

When it comes to the roofing and drainage industry, one of the crucial components is the gutter system. Properly functioning gutters are essential for protecting a building's foundation and preventing water damage. As an indispensable part of this system, gutter elbows play a significant role in redirecting water flow. For businesses involved in gutter manufacturing, finding the right gutter elbow machine can be a game-changer. In this article, we will explore the importance of gutter elbow machines, their features, and what to consider when looking for one for sale.

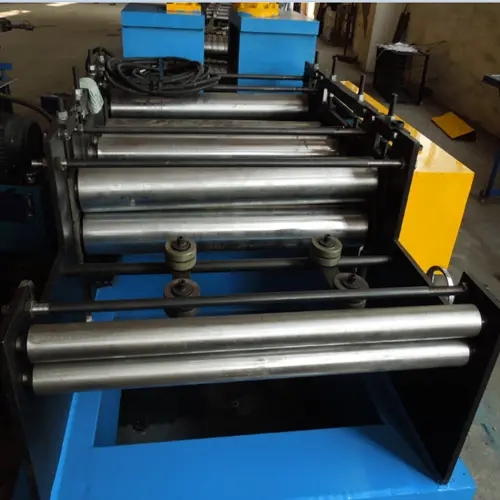

Understanding Gutter Elbow Machines

Gutter elbow machines are specialized equipment used in the production of elbow segments that connect straight gutter runs. These machines can bend metal and create precise angles, typically at 45 or 90 degrees, allowing for the smooth transition of water down the gutter system. The production process is essential for ensuring that gutters fit seamlessly into a building’s design and effectively channel water away from its structure.

Types of Gutter Elbow Machines

There are various types of gutter elbow machines available in the market, each designed to serve different needs

1. Manual Machines These are suitable for small-scale operations or businesses just starting. They require hands-on operation, making them less expensive but also less efficient.

2. Semi-Automatic Machines These machines bridge the gap between manual and fully automated processes. They reduce labor costs while maintaining control over the bending process.

3. Fully Automatic Machines Designed for high-volume production, these machines are equipped with advanced technology that enables the automatic feeding of materials, processing, and even quality control. They are perfect for large manufacturing facilities looking to maximize efficiency and output.

Key Features to Look For

When considering a gutter elbow machine for sale, it’s vital to evaluate certain features that can impact productivity and output quality

- Material Compatibility The machine should accommodate various types of metals commonly used in gutter production, such as aluminum, steel, and copper.

- Precision and Accuracy Look for machines that provide high precision in bending, allowing for consistent product quality and fit.

- User-Friendly Interface A machine with an intuitive control system will help operators reduce training time and minimize errors during production

.

- Speed and Efficiency Consider the throughput capabilities of the machine. Higher production speeds can significantly impact overall profit margins.

- Durability and Maintenance A well-built machine will endure the rigors of manufacturing. Additionally, easy maintenance features can help minimize downtime.

Pricing and Market Trends

The price of gutter elbow machines can vary widely based on features, capacity, and brand. Manual machines may cost a few thousand dollars, while fully automated systems can go upwards of $100,000. It is crucial to evaluate your business's needs and budget before making a purchase.

As the demand for new construction and renovations continues to grow, so does the market for gutter systems. This trend highlights the importance of investing in quality gutter elbow machines. The right equipment not only enhances production efficiency but also meets the increasing market demands for high-quality gutter systems.

Where to Buy

When looking for a gutter elbow machine for sale, consider the following places

- Manufacturers Buying directly from manufacturers may provide benefits such as warranties, customer support, and the ability to customize machines.

- Industry Expos Attending industry trade shows can give you hands-on experience with different machines and the opportunity to speak directly with suppliers.

- Online Marketplaces Numerous websites specialize in the sale of industrial machinery, often with user reviews and competitive pricing.

- Local Suppliers Developing relationships with local suppliers can provide ongoing support and immediate access to parts and service.

Conclusion

Investing in a gutter elbow machine is a significant decision that can enhance the efficiency and quality of gutter production. By understanding the types of machines available, their key features, and the market trends, businesses can make informed choices that align with their operational goals. Whether you are a startup or an established manufacturer, having reliable machine technology at your disposal can ensure that your products stand out in the competitive construction landscape.