The Gutter Downspout Roll Forming Machine Enhancing Efficiency in Construction

In the construction and roofing industry, the efficiency and quality of rainwater management systems are paramount. One essential component of these systems is the downspout, which directs rainwater from the gutters to the ground or drainage systems. The manufacturing of downspouts can be considerably streamlined with the use of a gutter downspout roll forming machine. This advanced piece of machinery not only enhances production efficiency but also ensures high-quality products.

What is a Gutter Downspout Roll Forming Machine?

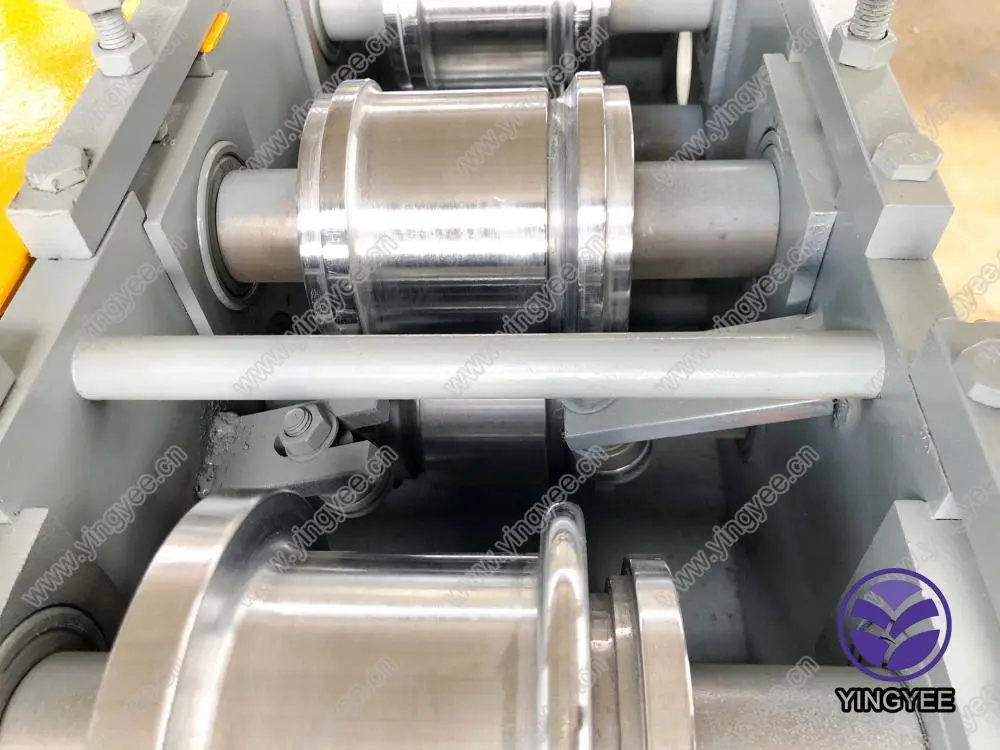

A gutter downspout roll forming machine is a piece of equipment specifically designed to create downspouts from metal sheets, typically aluminum or galvanized steel. The process begins with flat metal coils that are fed into the machine. Through a series of rollers, the machine gradually shapes the flat material into a continuous downspout profile. It can produce various sizes and shapes of downspouts, including rectangular, square, and round forms, catering to different building designs and water drainage requirements.

Advantages of Using a Roll Forming Machine

1. Efficiency and Speed Traditional methods of manufacturing downspouts often involve cutting and bending metal sheets, which can be labor-intensive and time-consuming. In contrast, roll forming is a continuous process. The machine can produce multiple lengths of downspouts in a fraction of the time, significantly increasing output.

2. Precision and Consistency Roll forming machines are engineered for precision. They ensure that each downspout is manufactured to exact specifications, reducing errors and the need for rework. This consistency in production not only saves time but also contributes to better quality control.

3. Cost-Effectiveness While the initial investment in a gutter downspout roll forming machine may be substantial, the long-term savings it offers are noteworthy. With reduced labor costs, minimized material waste, and faster production times, businesses can achieve a higher return on investment.

4. Customization Another advantage of roll forming is the ability to customize downspout profiles according to specific project requirements. The flexibility of the machine allows manufacturers to switch between different profiles quickly, accommodating various architectural styles and customer preferences.

5. Durability of Products The machines can work with high-quality materials that enhance the durability of the downspouts. When properly manufactured, these downspouts are resilient against weather conditions, ensuring longevity and reliability in drainage systems.

Applications in the Construction Industry

The gutter downspout roll forming machine plays a critical role in both residential and commercial construction projects. It is particularly beneficial in areas with heavy rainfall, where proper drainage systems are essential to prevent water damage to structures. Homes, office buildings, warehouses, and industrial facilities alike require efficiently manufactured downspouts for effective rainwater management.

Conclusion

The gutter downspout roll forming machine has revolutionized the way downspouts are manufactured, offering unmatched efficiency, precision, and customization. As the construction industry continues to prioritize sustainable practices and quality, investing in advanced machinery like the roll forming machine becomes increasingly important. With the ability to produce durable and reliable rainwater management solutions, this technology is not just a tool—it's a vital asset for modern construction practices. By embracing these innovations, manufacturers can improve their operations and provide better products that meet the demands of today’s construction landscape.