Gutter Downspout Roll Forming Machine Revolutionizing Rainwater Management

In modern construction and architecture, effective rainwater management systems are crucial for maintaining the durability and longevity of buildings. Among the key components of these systems are gutters and downspouts, which facilitate the safe drainage of rainwater from rooftops. One of the most innovative solutions that has emerged in recent years to streamline the production of these vital components is the gutter downspout roll forming machine.

What is a Gutter Downspout Roll Forming Machine?

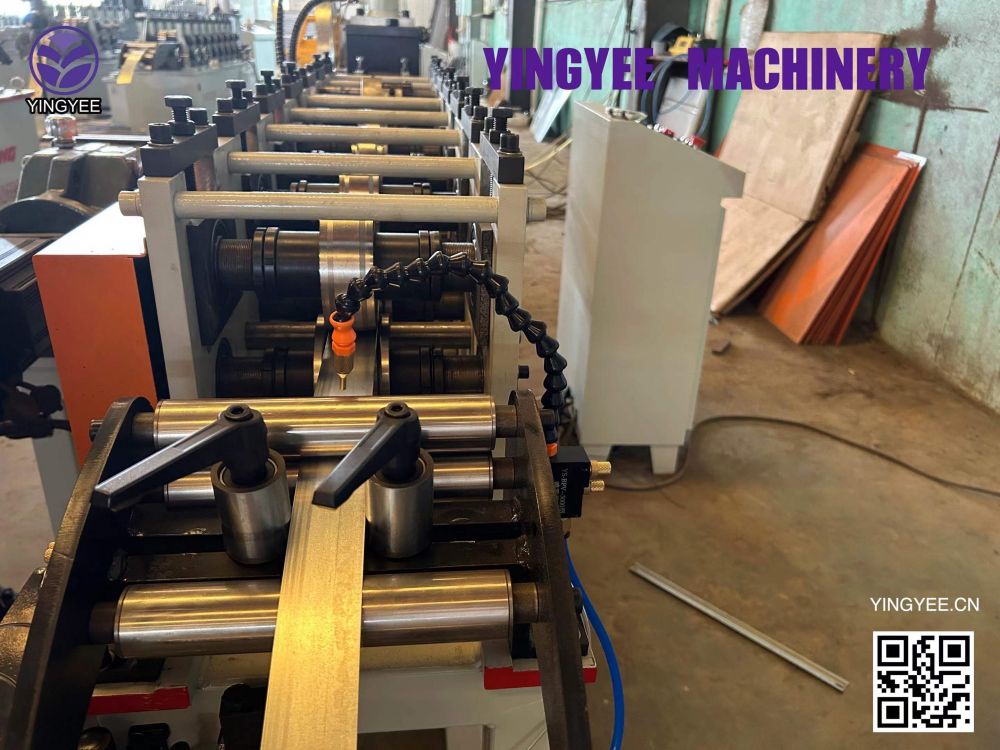

A gutter downspout roll forming machine is a specialized piece of machinery designed to produce seamless metal gutters and downspouts efficiently. The machine operates by feeding coils of metal, typically galvanized steel or aluminum, through a series of rollers that shape the material into the desired profile. This automated process not only minimizes waste but also ensures uniformity in design and dimensions, making it an essential tool for manufacturers focused on high-quality output.

Key Features and Benefits

1. Precision Engineering One of the standout features of a gutter downspout roll forming machine is its precision. The rollers are engineered to create exact shapes and sizes according to specifications, which helps to maintain the consistency of products being produced. This precision is particularly important in applications where accurate fitting is required.

2. Speed and Efficiency The roll forming process is significantly quicker than traditional methods of gutter and downspout manufacturing. Once set up, these machines can produce long strips of gutter or downspout material continuously. This high-speed production capability translates to reduced labor costs and faster turnaround times for projects.

3. Custom Profiles Many modern roll forming machines can be easily adjusted to create different profiles, allowing manufacturers to meet diverse client needs without requiring new machinery. This adaptability makes it easier for businesses to cater to the growing demand for custom gutters and downspouts.

4. Reduced Material Waste The roll forming process utilizes continuous strips of metal, which means there are minimal off-cuts and waste materials. This not only lowers production costs but also makes it a more environmentally friendly manufacturing option compared to other methods, such as stamping.

5. Durability The materials produced by gutter downspout roll forming machines are typically much more robust than their counterparts. The process itself enhances the structural integrity of the gutters and downspouts, ensuring they can withstand harsh weather conditions and last for years without significant degradation.

Applications in the Construction Industry

Gutters and downspouts manufactured using these machines are crucial in a variety of construction applications. They manage rainwater by directing it away from the foundation of buildings and preventing water damage, erosion, and mold growth. Furthermore, attractive and functional gutters enhance the aesthetic appeal of residential and commercial structures, contributing to their overall value.

Additionally, the rise of green building practices has increased the demand for efficient rainwater harvesting systems. Gutter downspout roll forming machines can accommodate these needs by producing components that integrate seamlessly with sustainable building designs.

Conclusion

As the construction industry continues to evolve, the importance of efficient and reliable rainwater management systems cannot be overstated. The gutter downspout roll forming machine is a game-changer, providing manufacturers with the tools they need to produce high-quality products quickly, efficiently, and at a lower cost. By investing in this technology, manufacturers can not only meet the diverse needs of their clients but also contribute to more sustainable construction practices. In a world where environmental considerations are becoming increasingly critical, the roll forming machine stands out as an innovative solution for the future of gutter and downspout manufacturing.