The Importance of Gutter Downpipe Roll Forming Machines in Modern Construction

In the realm of modern construction and building maintenance, efficient drainage systems are crucial to ensure the longevity and integrity of structures. This is where gutter downpipe roll forming machines come into play. These machines have revolutionized how gutters and downpipes are manufactured, providing speed, efficiency, and precision in the production process.

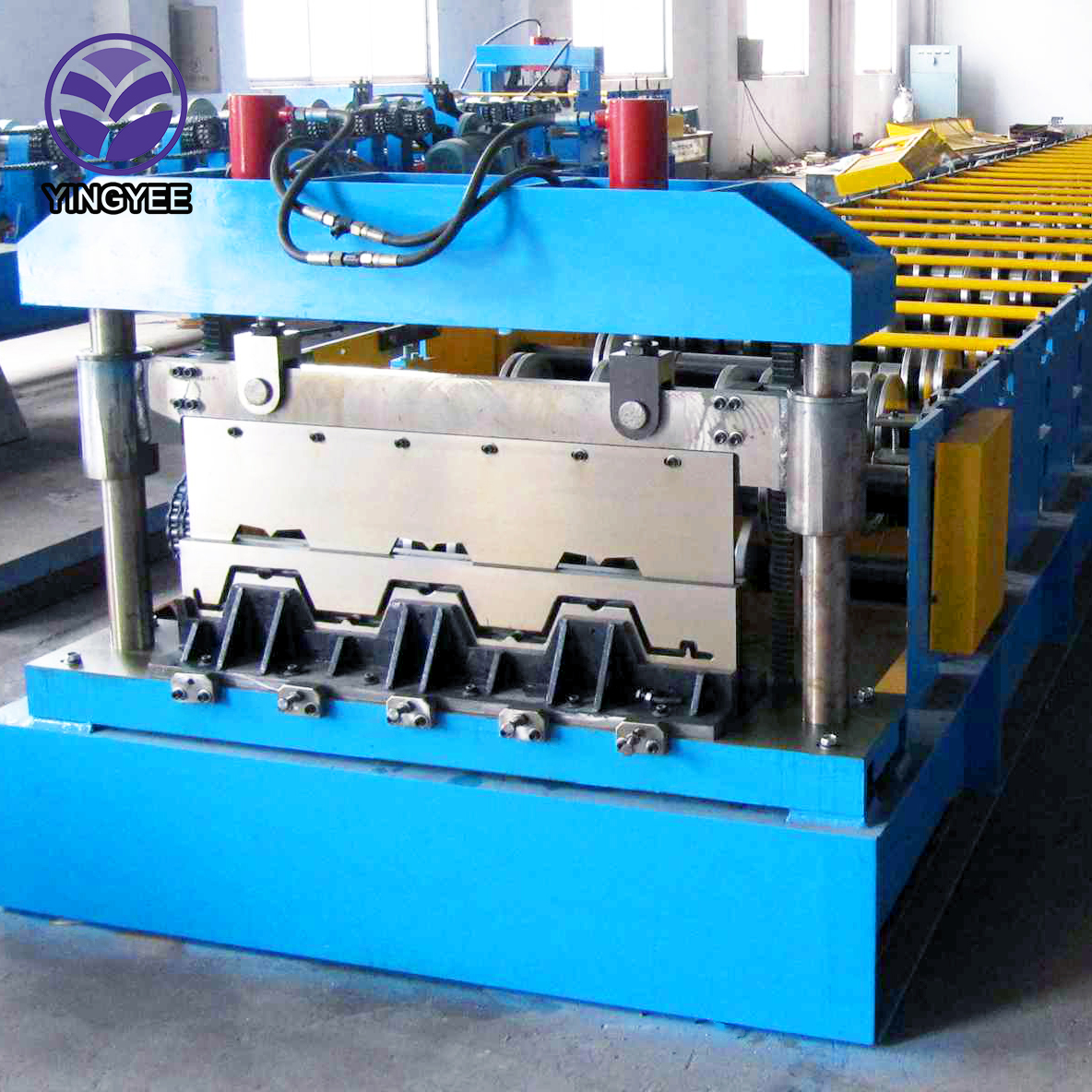

Understanding Roll Forming Technology

Roll forming is a continuous bending process that shapes metal sheets into specific profiles by passing them through a series of rollers. This technique is particularly advantageous for producing gutter and downpipe systems, as it allows for long lengths of consistent profiles and minimizes waste. The gutter downpipe roll forming machine takes steel or aluminum sheets and processes them into the desired shape, typically a U or L-shaped profile, which is essential for effective drainage.

Efficiency and Customization

One of the primary benefits of using a gutter downpipe roll forming machine is efficiency. Traditional manufacturing methods can be slow and labor-intensive, often resulting in higher production costs. However, roll forming machines can produce large volumes of products in a shorter time frame, significantly reducing labor costs. Moreover, these machines can be easily adjusted to create different profiles and dimensions, allowing manufacturers to cater to a wide range of customer needs and preferences. This flexibility is vital in today’s market, where customization is increasingly demanded.

Precision Engineering for Quality Products

The accuracy of manufacturing is another critical advantage offered by gutter downpipe roll forming machines. With advanced computer controls and feedback systems, modern roll formers ensure that every piece produced meets strict specifications. This precision is not only essential for the functionality of the gutters and downpipes but also for aesthetic considerations in architectural design. High-quality products minimize the risk of leaks and structural damage, ensuring that buildings maintain their performance over time.

Material Versatility and Sustainability

Gutter downpipe roll forming machines typically work with a variety of materials, including galvanized steel, aluminum, and stainless steel. This versatility allows manufacturers to choose materials that best suit their specific application while considering factors such as climate, cost, and durability. Moreover, by utilizing materials that are recyclable and sustainable, the industry can contribute positively to environmental conservation efforts.

Conclusion

As urbanization continues to expand and demands for commercial and residential construction increase, the importance of efficient drainage solutions becomes even more apparent. Gutter downpipe roll forming machines stand at the forefront of this evolution, providing an essential service in producing effective drainage systems. Their efficiency, precision, and ability to customize products are vital in meeting both market demands and the growing need for sustainable building practices.

In summary, gutter downpipe roll forming machines are not just a technological advancement; they represent a shift towards smarter, more efficient manufacturing in the construction industry. As we move forward, these machines will play a crucial role in ensuring that buildings remain durable and functional, safeguarding structures against the relentless forces of nature. In light of all these factors, it is clear that investing in gutter downpipe roll forming technology is a strategic choice for manufacturers looking to thrive in the competitive construction landscape.