Gutter Cutting Machines Revolutionizing Water Management in Construction

In the construction and civil engineering sectors, water management is a crucial component, especially when it comes to maintaining the integrity of structures and minimizing water-related damages. One essential tool that has gained substantial attention in recent years is the gutter cutting machine. This innovation is designed specifically for creating channels that direct rainwater away from foundations and other vulnerable areas, thus playing an important role in enhancing drainage efficiency.

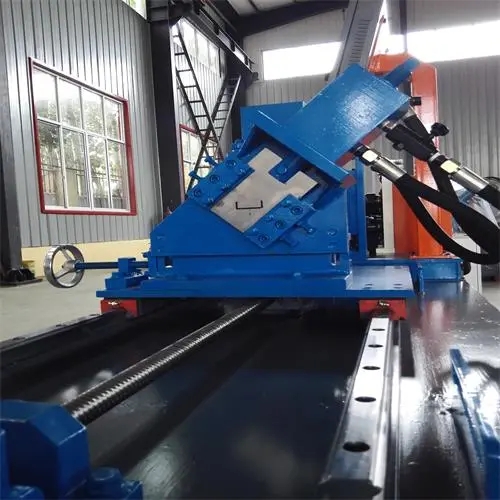

Understanding Gutter Cutting Machines

Gutter cutting machines are specialized equipment used to create gutters or channels in various surfaces, primarily concrete and asphalt. These machines are engineered to enable precise cuts facilitating the installation of drainage systems in commercial, residential, and infrastructural projects. The primary objective of these machines is to divert rainwater away from structures, preventing erosion, flooding, and potential damage.

Most gutter cutting machines are equipped with advanced features such as high-precision blades that can adjust to different depths and widths, reversing capabilities for ease of operation, and robust engines that ensure efficiency. They come in various designs, from manual machines suited for small projects to heavy-duty models capable of cutting large areas rapidly.

The Benefits of Gutter Cutting Machines

1. Efficiency One of the standout advantages of gutter cutting machines is their ability to significantly reduce labor time and effort. Traditional methods of creating gutters were labor-intensive and often required multiple workers and tools. With these machines, a single operator can execute the task with precision and speed.

2. Precision Engineering Gutter cutting machines provide precise cuts that are essential for effective water management. Incorrectly cut gutters can lead to water pooling, which diminishes the efficiency of drainage systems and can lead to structural damage over time. These machines minimize human error by ensuring consistent depth and width with every cut.

3. Versatility These machines are designed for various applications, making them suitable for different types of projects. Whether it involves cutting gutters for roads, parking lots, or residential driveways, gutter cutting machines can handle diverse materials and surface conditions.

4. Cost-Effectiveness By reducing labor costs and increasing the speed of project completion, gutter cutting machines can lead to significant savings for contractors and project managers. This can free up resources for allocating to other vital project areas.

5. Improved Safety Safety is a priority on any job site. The use of gutter cutting machines helps to minimize the risk of injuries associated with manual cutting methods. The design of these machines allows for operator safety while efficiently performing the task, contributing to safer work environments.

The Future of Gutter Cutting Technology

As technology continues to evolve, so does the development of gutter cutting machines. Future innovations may include automated features that allow for programmable cutting patterns, remote control operations, and integration with advanced drainage systems that monitor water flow. Additionally, manufacturers are likely to focus on producing more eco-friendly machines, utilizing electric power sources instead of traditional fuel, thus reducing the carbon footprint associated with construction activities.

Moreover, as municipalities and governments become increasingly aware of the importance of effective water management, the demand for gutter cutting systems is expected to rise. This need will consequently spur innovation, leading to even more efficient and specialized equipment.

Conclusion

In conclusion, gutter cutting machines symbolize a significant advancement in the construction industry, enabling more efficient and precise water management solutions. Their role in preventing water-related issues cannot be overstated, as they contribute to the longevity and durability of buildings and infrastructure. By investing in quality gutter cutting equipment, contractors can not only streamline their operations but also provide enhanced solutions to the pressing challenges of water management. As we move forward, the integration of smart technology and sustainability will further refine these machines, ushering in a new era of construction efficiency and environmental responsibility.