The Gutter Cold Roll Forming Machine Revolutionizing Gutter Production

In the world of construction and building materials, the demand for high-quality roofing systems is ever-increasing. Among the essential components of a roofing system are gutters, which efficiently channel rainwater away from buildings, preventing water damage and structural issues. The manufacturing process of gutters has seen significant advancements, particularly with the introduction of the gutter cold roll forming machine. This innovative piece of equipment is transforming the way gutters are produced, making the process more efficient and cost-effective.

Understanding Cold Roll Forming

Cold roll forming is a manufacturing process that involves shaping metal sheets into specific profiles at room temperature without the need for heating. This technique offers various advantages, including improved strength, uniformity, and reduced waste. The gutter cold roll forming machine utilizes this process to create gutters of various sizes and shapes, catering to the diverse needs of construction projects.

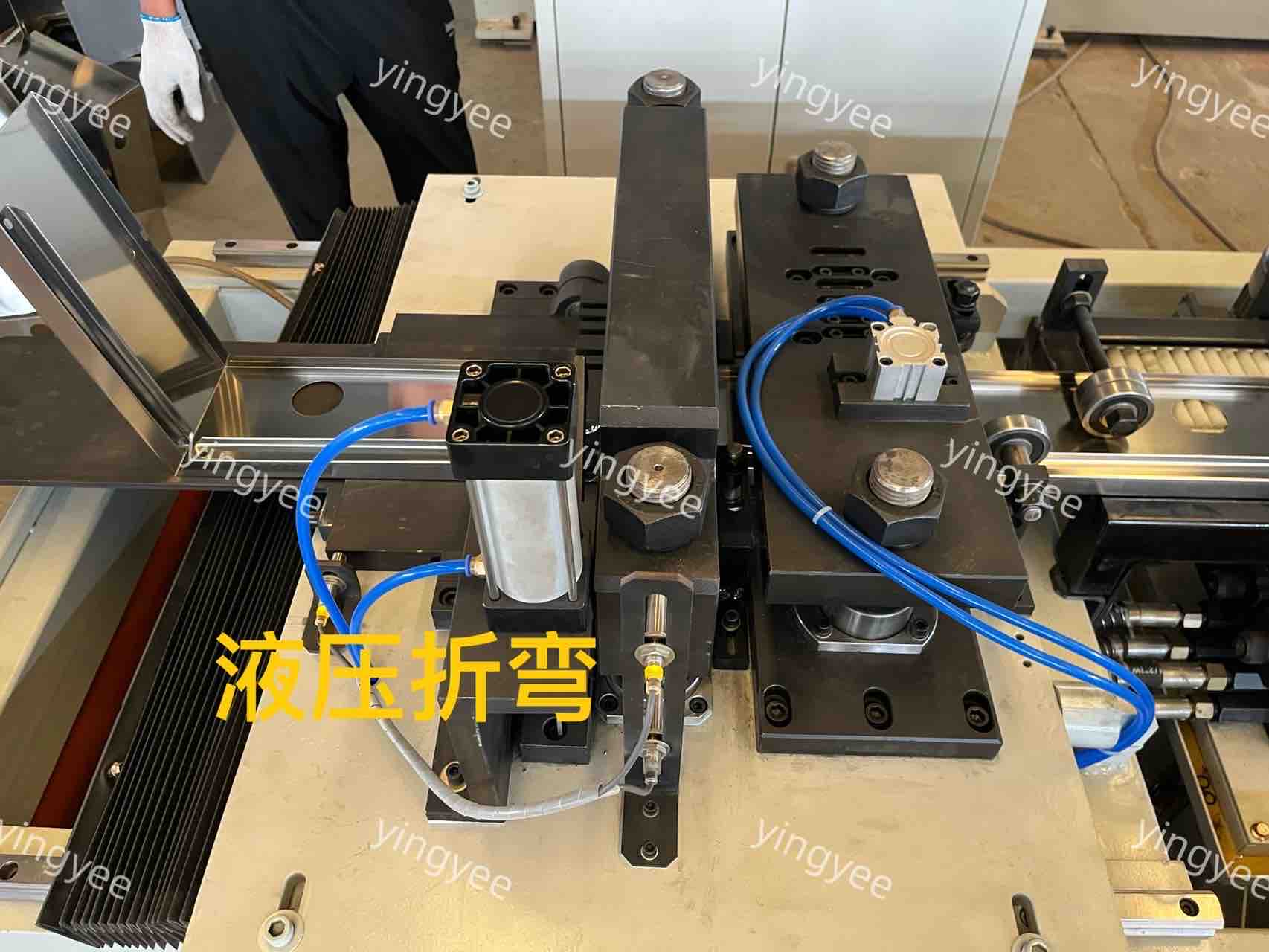

The machine operates by feeding metal coils, typically made of galvanized steel, aluminum, or other corrosion-resistant materials, through a series of rollers. These rollers gradually shape the metal into the desired gutter profile. The precision of these machines allows for consistent production, meaning that every length of gutter produced will meet specific design criteria and industry standards.

Advantages of Gutter Cold Roll Forming Machines

1. Efficiency and Speed One of the primary benefits of using a gutter cold roll forming machine is its ability to produce large quantities of gutters swiftly. Automated features and high-speed operation minimize production time, allowing manufacturers to fulfill large orders quickly.

2. Cost-Effectiveness The use of a cold roll forming machine can significantly reduce material costs. The precision of the manufacturing process minimizes waste, ensuring that virtually every inch of the metal used contributes to the final product. Additionally, the durability of the formed gutters means less frequent replacement and maintenance for end-users, offering long-term savings.

3. Customization Gutter cold roll forming machines provide the flexibility to create customized profiles. Depending on a project's specific requirements, manufacturers can adjust the machine settings to produce different shapes, sizes, and finishes. This level of customization is not only beneficial for aesthetic purposes but also enhances functionality in managing water runoff.

4. Quality Control With advancements in technology, modern gutter cold roll forming machines often come equipped with sophisticated monitoring systems that ensure quality control throughout the manufacturing process. This mitigates defects and ensures that each gutter meets required standards.

5. Sustainability Many manufacturers are increasingly conscious of the environmental impact of their processes. Cold roll forming is considered a sustainable manufacturing technique as it generates less waste and often uses recyclable materials. Investing in a gutter cold roll forming machine aligns production practices with growing sustainability goals in the construction industry.

Applications of Gutter Cold Roll Forming Machines

Gutter cold roll forming machines are not just limited to the production of gutters for residential buildings; they are widely used in commercial and industrial applications as well. From simple residential systems to complex commercial rainwater management solutions, these machines can accommodate a wide range of uses.

Moreover, as building codes become more stringent regarding rainwater management and environmental considerations, having the ability to produce high-quality, customized gutters has become increasingly crucial for manufacturers. The gutter cold roll forming machine plays a pivotal role in ensuring that businesses can adapt to these evolving demands efficiently.

Conclusion

The gutter cold roll forming machine represents a significant evolution in the way gutters are manufactured. By combining efficiency, customization, and sustainability, this technology is setting new standards in the industry. Manufacturers equipped with such machines can better meet market demands while contributing to improved construction practices. As the need for effective water management solutions continues to grow, so too will the importance of innovative manufacturing technologies like the gutter cold roll forming machine.