Understanding Gutter Cold Roll Forming Machines

In the construction and manufacturing industries, the importance of efficient and precise machinery cannot be overstated. One such machine that has garnered significant attention is the gutter cold roll forming machine. This specialized equipment is designed to produce gutters, downspouts, and other related components essential for water management in buildings and infrastructure.

What is a Gutter Cold Roll Forming Machine?

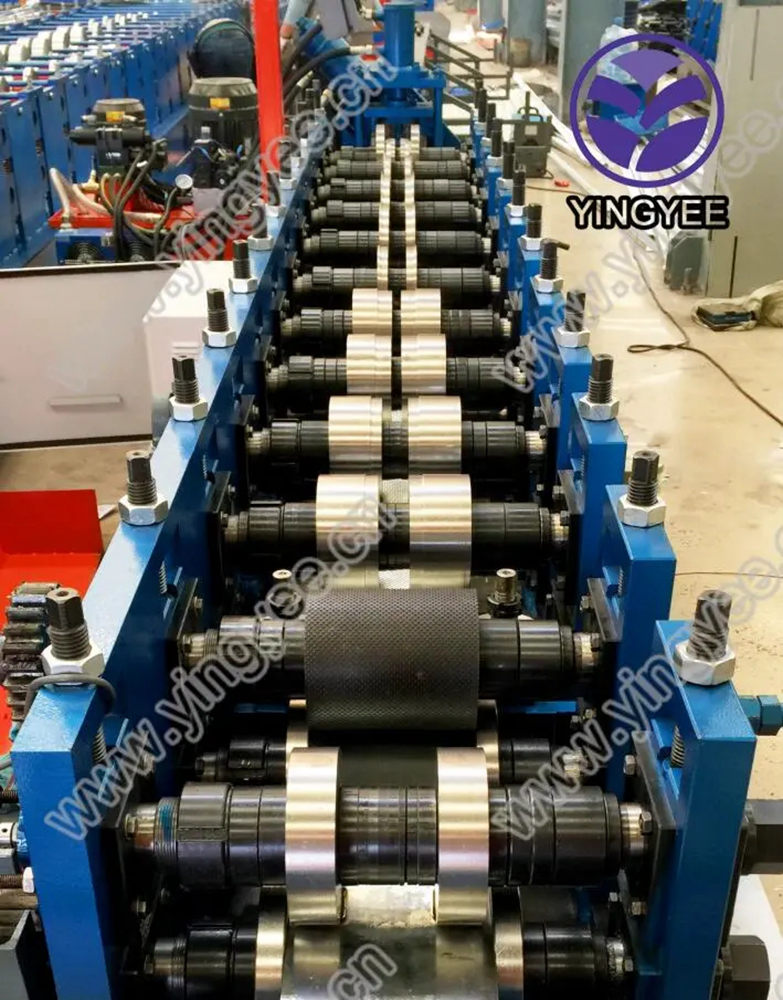

A gutter cold roll forming machine is a type of machinery that converts flat steel coils into pre-shaped gutters. The process is called “cold” rolling because it shapes the material at room temperature, which allows for the preservation of its mechanical properties. By employing a series of rollers and dies, the machine progressively bends and shapes the coil into the desired profile.

These machines can produce various designs and sizes of gutters, catering to diverse construction requirements. The final product is not only durable and weather-resistant but also aesthetically pleasing, which is crucial for architectural coherence in residential and commercial constructions.

The Roll Forming Process

The roll forming process consists of several stages. Initially, a coil of sheet metal is fed into the machine, where it is uncoiled. The material is then guided through a series of rollers, each designed to make incremental bends until the desired gutter shape is achieved. The precision of this process is paramount; each bend must be consistent to ensure proper fit and function during installation.

Once the roll forming is complete, additional processes may follow, such as cutting the formed gutters to specified lengths and adding features like seams or openings for drainage. The result is a high-quality product that meets the stringent demands of modern construction.

Applications of Gutter Cold Roll Forming Machines

Gutter cold roll forming machines are essential in various applications. Primarily, they are used for manufacturing gutters and downspouts that play a crucial role in directing rainwater away from buildings, preventing water damage and flooding. Properly installed gutter systems are vital for maintaining the integrity of roofs and foundations.

Moreover, these machines are also utilized in the production of fascia boards, soffits, and other related components. This versatility makes them valuable in both residential and commercial markets. They can handle different materials as well, including galvanized steel, aluminum, and stainless steel, further broadening their application scope.

Benefits of Using Gutter Cold Roll Forming Machines

One of the primary benefits of using gutter cold roll forming machines is the efficiency of production. The automation and speed of the process allow manufacturers to produce large quantities of products in a short period. This is particularly advantageous in large construction projects where time is of the essence.

Additionally, the precision offered by roll forming machines minimizes waste. Material is utilized efficiently, reducing costs and promoting sustainability. The consistent quality of the gutters produced ensures fewer defects and reworks, which can significantly enhance overall profitability.

Furthermore, the durability of the products made from these machines translates to longevity in the market. Well-formed gutters can withstand harsh weather conditions, thus providing value to builders and end-users alike.

Conclusion

In summary, gutter cold roll forming machines represent a vital component of modern manufacturing in the construction industry. They offer efficiency, precision, and versatility in producing high-quality gutter systems essential for effective water management. As technology continues to advance, these machines are likely to evolve further, incorporating innovations that enhance production capabilities and product quality.

Investing in a gutter cold roll forming machine can significantly benefit manufacturers by improving production speed, reducing waste, and ensuring the delivery of superior products. With their increasing importance, these machines are set to play a pivotal role in shaping the future of construction and infrastructure development.