The Importance of Guardrail Forming Machines in Modern Infrastructure

In the realm of modern infrastructure development, safety takes precedence as one of the primary considerations. With increasing vehicular traffic and the continuous expansion of road networks, the need for effective traffic management solutions has become more critical than ever. One such solution is the installation of guardrails, which play a vital role in preventing accidents and ensuring the safety of both drivers and pedestrians. At the heart of this vital component of road safety lies the innovative guardrail forming machine.

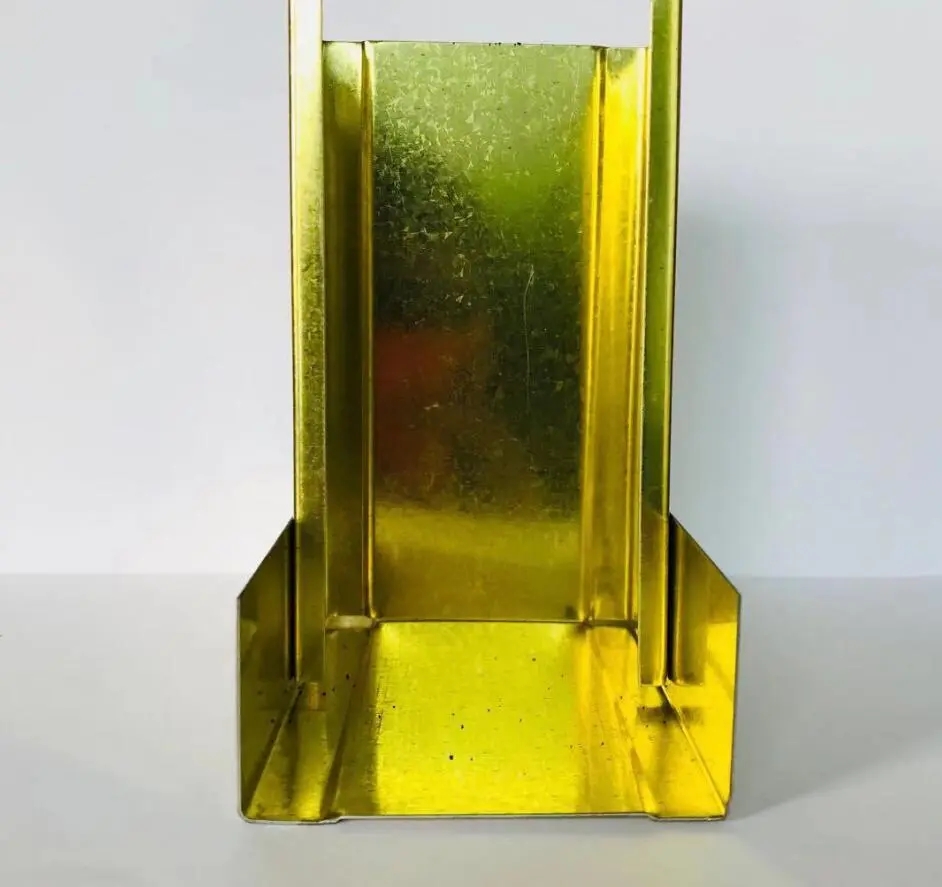

What is a Guardrail Forming Machine?

A guardrail forming machine is a specialized piece of equipment designed to fabricate guardrails efficiently and with precision. These machines utilize advanced technology and engineering methods to create guardrails that meet stringent safety standards and specifications. They can manufacture various types of guardrails, including the W-beam, thrie-beam, and other custom designs, ensuring that the guardrails can withstand the impacts of vehicles and effectively protect occupants and infrastructure.

How Does It Work?

The operation of a guardrail forming machine is both fascinating and complex. Typically, the process begins with the loading of raw materials, usually sheets of steel, into the machine. The machine then undergoes several stages, including cutting, bending, and punching. Through a series of rollers and forming devices, the steel is shaped into the desired guardrail design. This process is not only automated but also highly efficient, allowing manufacturers to produce large quantities of guardrails in a relatively short time.

Additionally, advanced guardrail forming machines incorporate computer numerical control (CNC) technology, enabling precise cuts and bends that adhere to the specifications required for safety and durability

. This technological integration significantly reduces human error and enhances the overall quality of the final product.The Benefits of Using Guardrail Forming Machines

The use of guardrail forming machines offers numerous advantages that are essential for manufacturers and infrastructure developers. Firstly, these machines increase production efficiency, allowing for quicker turnaround times on projects. With the ability to produce a large volume of guardrails, companies can meet the rising demands of infrastructure development without compromising on quality.

Secondly, guardrail forming machines ensure consistency in the quality of the guardrails produced. The precision of CNC technology results in uniformity, which is crucial in maintaining safety standards across different installations. Consistent quality also fosters increased trust and reliability among clients and contractors.

Moreover, the incorporation of automation in guardrail production helps reduce labor costs, as fewer workers are required to operate these machines compared to manual manufacturing methods. This efficiency translates into cost savings for companies and ultimately benefits taxpayers, as public infrastructure projects can be completed more economically.

The Role of Sustainability

In recent years, there has been a growing focus on sustainability within the manufacturing sector. Guardrail forming machines can be an environmentally friendly choice, particularly when they utilize recycled materials in their production process. This reduces the need for raw resources and minimizes waste, aligning with global efforts to promote sustainable practices in construction and infrastructure.

Conclusion

As the demand for safer roads continues to rise, guardrail forming machines will play an increasingly vital role in the manufacturing of this essential component of traffic management systems. The advanced technology and efficiency these machines offer not only support infrastructure development but also contribute to overall road safety, saving lives and reducing accidents. By investing in guardrail forming machines, manufacturers can ensure that they are meeting the growing needs of modern society while prioritizing safety and sustainability.