The Importance of Grain Storage Roll Forming Machines

In the agricultural sector, efficient storage solutions for grains are crucial for maintaining food security and enhancing farmers' profitability. One revolutionary technology that has gained prominence in recent years is the grain storage roll forming machine. This innovative equipment plays a pivotal role in the manufacturing of high-quality, durable storage structures, ensuring that grains are protected from various environmental factors.

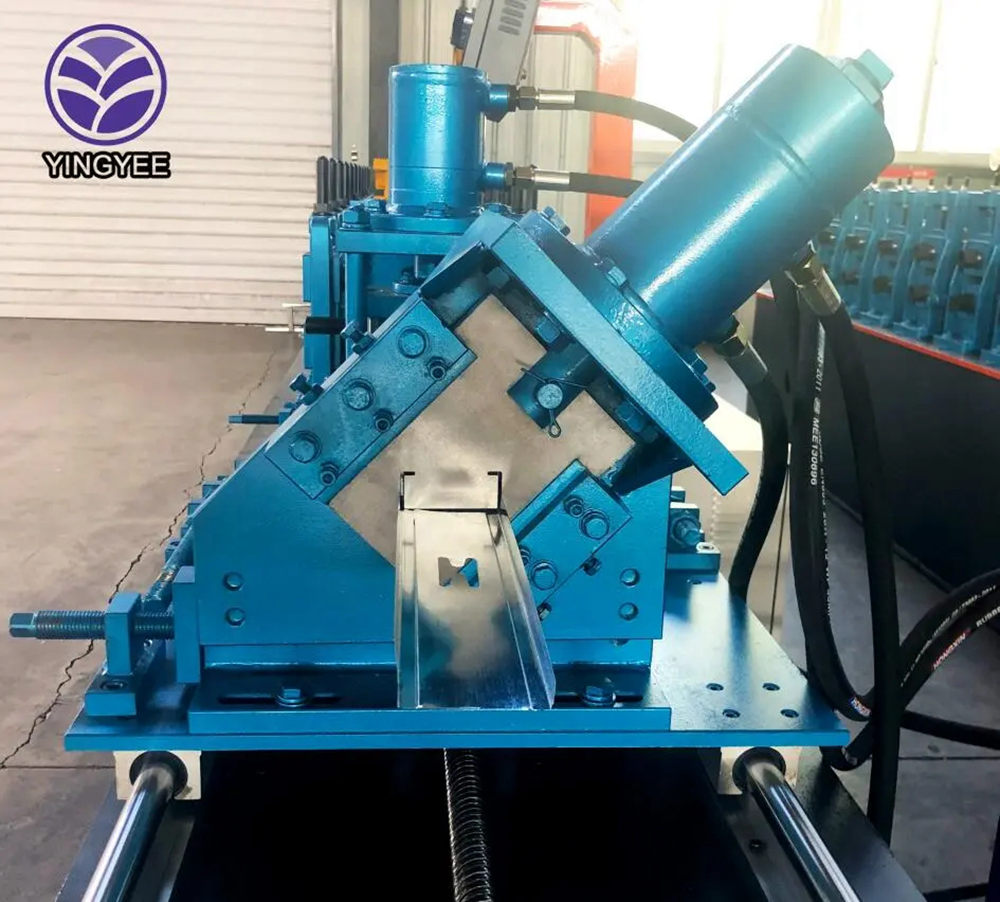

Understanding Roll Forming Technology

Roll forming is a continuous bending process in which a long strip of metal, usually coiled steel, is progressively shaped into specific configurations as it passes through a series of rollers. This technique is widely used in the production of various metal components due to its efficiency, precision, and ability to create complex shapes. When applied in grain storage, roll forming machines produce metal sheets or panels that are then used to construct silos, bins, and other storage facilities.

Key Benefits of Grain Storage Roll Forming Machines

1. Durability and Strength One of the primary advantages of using roll formed materials in grain storage is their enhanced durability. The continuous sheets produced by these machines have fewer weak points compared to welded structures, resulting in stronger and more reliable storage solutions. This is crucial for withstanding the heavy loads of grain and the pressures of storage conditions.

2. Cost-Effectiveness Roll forming is a cost-effective manufacturing process. The continuous operation minimizes waste material, and the high-speed production reduces labor costs and time. This efficiency translates to lower overall costs for grain storage manufacturers and, subsequently, for farmers who invest in these storage solutions.

3. Customization Grain storage roll forming machines can be designed to produce a variety of profiles, accommodating different storage needs. Customers can specify dimensions, thickness, and coatings based on their unique requirements. This flexibility ensures that farmers and agricultural businesses can tailor their storage solutions to meet specific demands.

4. Ease of Installation The roll formed panels produced by these machines are often lightweight and easy to handle. This characteristic simplifies the installation process, allowing for quicker setup times and reduced labor costs on-site. Efficient installation is vital, especially during peak harvest times when farmers need to safeguard their produce swiftly.

5. Sustainability As the agricultural industry increasingly focuses on sustainability, using roll forming technology aligns with these goals. The process generates less scrap material than traditional manufacturing methods, and many roll forming machines are capable of utilizing recycled materials, contributing to an eco-friendlier approach to grain storage.

Applications in the Agricultural Sector

Grain storage roll forming machines are employed in various applications, from small-scale farming operations to large commercial storage facilities. The roll-formed metal structures are particularly advantageous for grain silos, which require robust and reliable designs to protect crops from pests, moisture, and temperature fluctuations. These machines can also produce parts for accompanying systems, such as aeration and drying systems, further enhancing grain preservation.

Future of Grain Storage Solutions

As global demand for food continues to rise, the agricultural sector must adopt innovative solutions to ensure effective grain storage and management. Grain storage roll forming machines represent a significant advancement in technology, offering enhanced durability, flexibility, and sustainability. As farms strive to optimize their operations and maintain high standards for grain quality, the adoption of these machines is likely to increase.

Conclusion

The integration of grain storage roll forming machines into agricultural practices has revolutionized the way farmers store their produce. By providing durable, cost-effective, and customizable storage solutions, these machines play an essential role in ensuring food security and optimizing agricultural efficiencies. As technology continues to evolve, the future of grain storage looks promising, with roll forming machines at the forefront of innovation.