Glazed Tile Steel Roofing Making Machine Revolutionizing Construction Industry

In the ever-evolving world of construction, the materials and technology used play a crucial role in ensuring sustainability, efficiency, and durability. One of the most significant advancements in this realm is the development of the glazed tile steel roofing making machine. This innovative equipment is not only transforming the way roofs are manufactured but is also enhancing the overall quality and appeal of modern buildings.

Understanding Glazed Tile Steel Roofing

Before delving into the specifics of the roofing making machine, it's essential to grasp what glazed tile steel roofing entails. This type of roofing combines the aesthetic appeal of traditional tiles with the durability and strength of steel sheets. Glazed tiles, typically coated with a layer of glossy finish, provide an attractive appearance while ensuring resistance to weather elements, corrosion, and UV rays. These roofs are increasingly adopted in residential, commercial, and industrial sectors due to their excellent performance and long lifespan.

The Functionality of the Roofing Making Machine

The glazed tile steel roofing making machine is fundamentally a production line that automates the entire process of creating roofing tiles. It encompasses various stages, including sheet metal rolling, profiling, cutting, and glazing. Here’s a closer look at its functionality

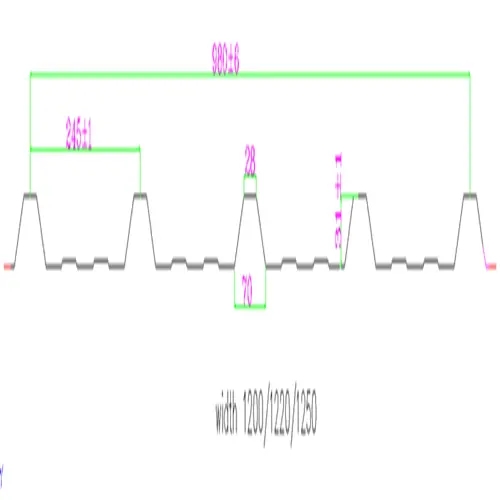

1. Material Preparation The process begins with high-quality steel coils. The machine rolls and shapes these coils into desired tile profiles, ensuring precision in dimensions and design.

2. Forming and Profiling Once rolled, the steel is formed into tile shapes that mimic traditional rooftops. Advanced dies and molds are used to achieve various styles and patterns, providing flexibility in design.

3. Glazing Process The unique aspect of this machine is its glazing capability. After profiling, the tiles are subjected to a glazing process that involves applying a protective and aesthetic layer. This step is crucial as it enhances the visual appeal and provides additional protection against the elements.

4. Cutting and Finishing After glazing, the tiles are cut to specific lengths and undergo quality checks to ensure that they meet the industry standards. This quality assurance is vital for customer satisfaction and longevity.

5. Automatic Control Systems Modern machines are equipped with advanced control systems that allow for precise adjustments in the manufacturing process. Operators can easily customize settings according to specific project requirements, improving efficiency and reducing waste.

Advantages of Using Glazed Tile Steel Roofing Making Machines

The adoption of glazed tile steel roofing making machines offers numerous advantages for manufacturers, builders, and homeowners alike

- Efficiency These machines drastically reduce production time compared to manual methods, allowing manufacturers to meet high demands swiftly.

- Quality Consistency Automation ensures that each tile produced is uniform in quality and appearance, which is crucial for large construction projects.

- Durability Glazed steel roofs made using this equipment are known for their strength and resistance, providing long-term protection against harsh weather conditions.

- Cost-Effectiveness Although the initial investment in a roofing making machine may be considerable, the reduction in labor costs and increased production efficiency leads to significant long-term savings.

- Sustainable Manufacturing Many machines are designed to minimize waste and energy consumption, aligning with the growing emphasis on sustainable construction practices.

Future of Roofing Production

As the construction industry continues to advance, glazed tile steel roofing making machines are expected to evolve further. Innovations such as enhanced automation, improved glazing techniques, and environmentally friendly materials will likely drive the next phase of development. Additionally, as design trends shift towards more customizable and visually appealing structures, the demand for such machinery will only increase.

In conclusion, the glazed tile steel roofing making machine plays a pivotal role in modern construction, bridging the gap between traditional aesthetics and contemporary durability. Its ability to produce high-quality, visually appealing roofs efficiently and sustainably represents a significant leap forward for the industry. As builders and homeowners continue to seek innovative solutions for their roofing needs, this technology will undoubtedly remain at the forefront of construction advancements.