Glazed Tile Sheet Forming Machine Revolutionizing Tile Production

In the ever-evolving construction and manufacturing industries, the introduction of advanced machinery has significantly enhanced production efficiency and quality. One such innovation is the glazed tile sheet forming machine, a pivotal equipment for manufacturers involved in tile production. This machine not only streamlines the manufacturing process but also ensures that the end product meets the aesthetic and functional demands of modern architecture.

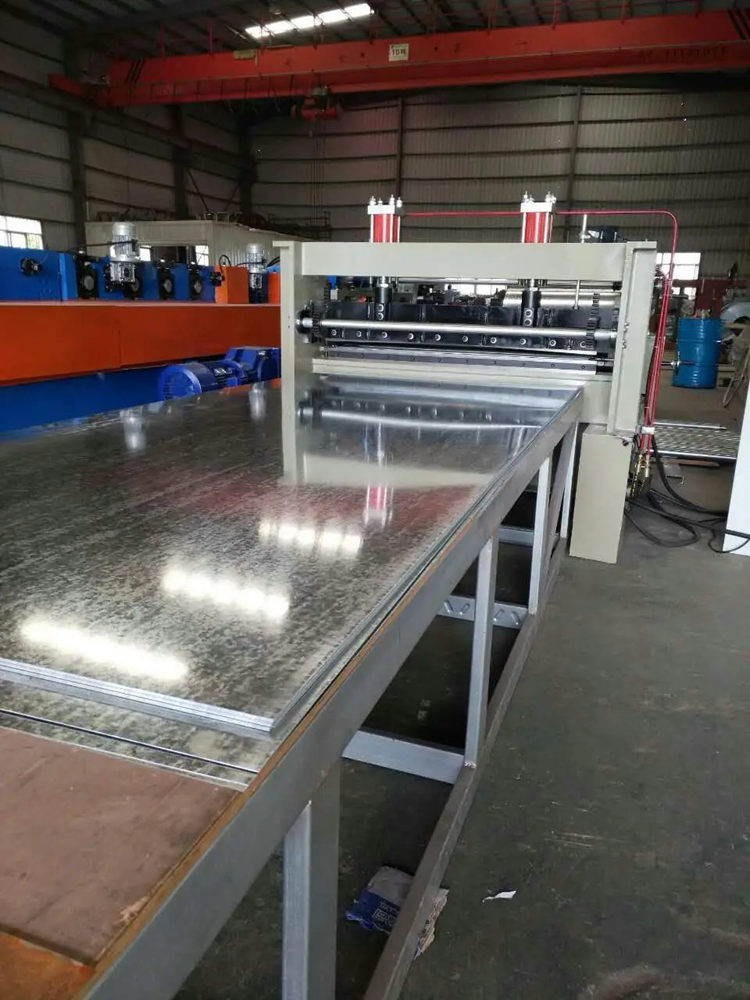

The glazed tile sheet forming machine is designed to produce high-quality glazed tiles widely used for flooring, wall cladding, and roofing. These tiles are known for their durability, water resistance, and ease of maintenance, making them a popular choice among builders and homeowners alike. The machine operates on a continuous process that involves mixing raw materials, forming sheets, applying glaze, and then firing the tiles in a kiln.

The first step in the operation of a glazed tile sheet forming machine is the preparation of the raw materials. Typically, this includes a mixture of clay, sand, and other additives that enhance the properties of the tiles. The precision in the mixture is crucial, as it directly affects the quality of the final product. Once the materials are thoroughly mixed, they are fed into the forming section of the machine. This section utilizes advanced molding techniques to create uniform sheets of tile, ensuring consistency in size and thickness.

After the tiles are formed, they move to the glazing station, where a liquid glaze is applied. This glaze not only enhances the aesthetic appeal of the tiles by providing a shiny finish but also adds a layer of protection against environmental factors. The application of glaze is a critical stage, as it determines the overall look and feel of the tiles. Automated systems within the machine ensure precise and uniform coating, reducing the chances of defects.

The final step in the process is firing the glazed tile sheets in a high-temperature kiln. This stage is essential for strengthening the tiles and ensuring that the glaze adheres properly. The kiln’s temperature and firing duration are carefully controlled to achieve optimal results, resulting in tiles that are not only visually appealing but also durable and resistant to wear and tear.

Another significant advantage of using a glazed tile sheet forming machine is the reduction of labor costs and production time. Automation in tile manufacturing allows for higher output and consistent quality, making it an attractive investment for tile manufacturers looking to enhance their production capabilities. Moreover, the increased efficiency brought about by such machines can lead to a reduction in the overall environmental impact, as less energy is consumed per unit of product.

In conclusion, the glazed tile sheet forming machine is a game changer in the tile manufacturing industry. By combining efficiency, quality, and aesthetic appeal, this machine supports the growing demand for durable and attractive tiles in contemporary construction. As technology continues to advance, we can anticipate further innovations that will enhance the capabilities of such machines, paving the way for even more sustainable and efficient production processes in the future.